A pickling solution for copper base material with corrosion inhibition effect

A substrate acid and corrosion inhibition technology, which is applied in the field of copper substrate pickling solution, can solve the problems of poor biodegradability, low corrosion inhibition efficiency of corrosion inhibitors, and high cost, and achieve cheap raw materials, stable corrosion inhibition performance, and applicable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

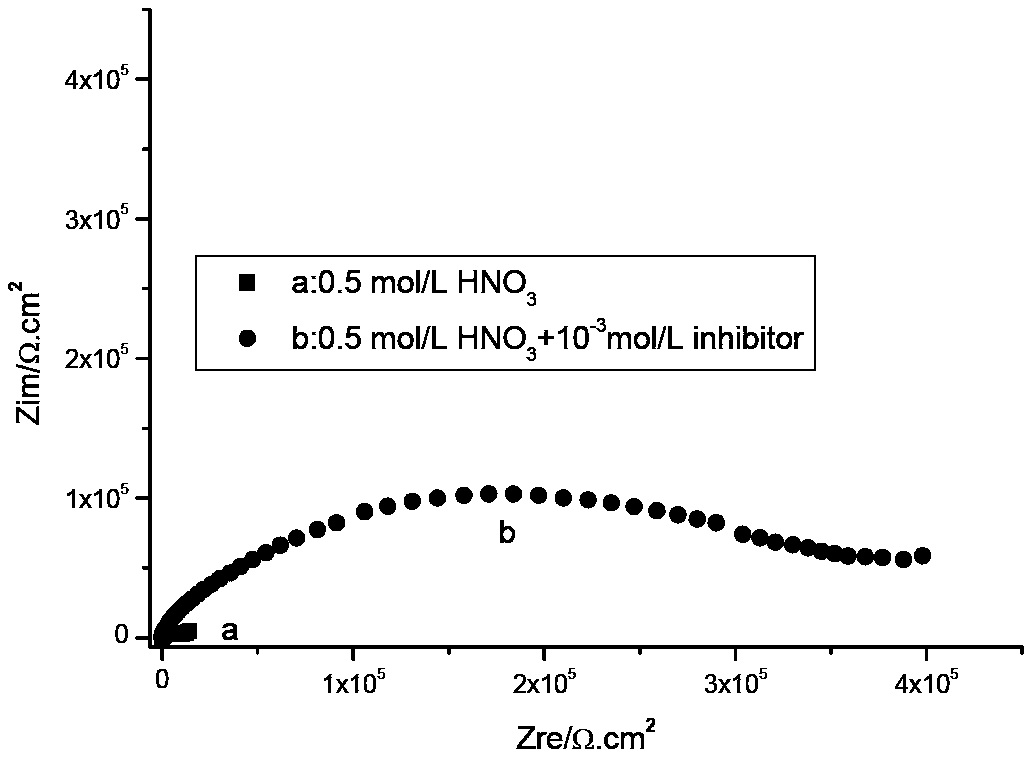

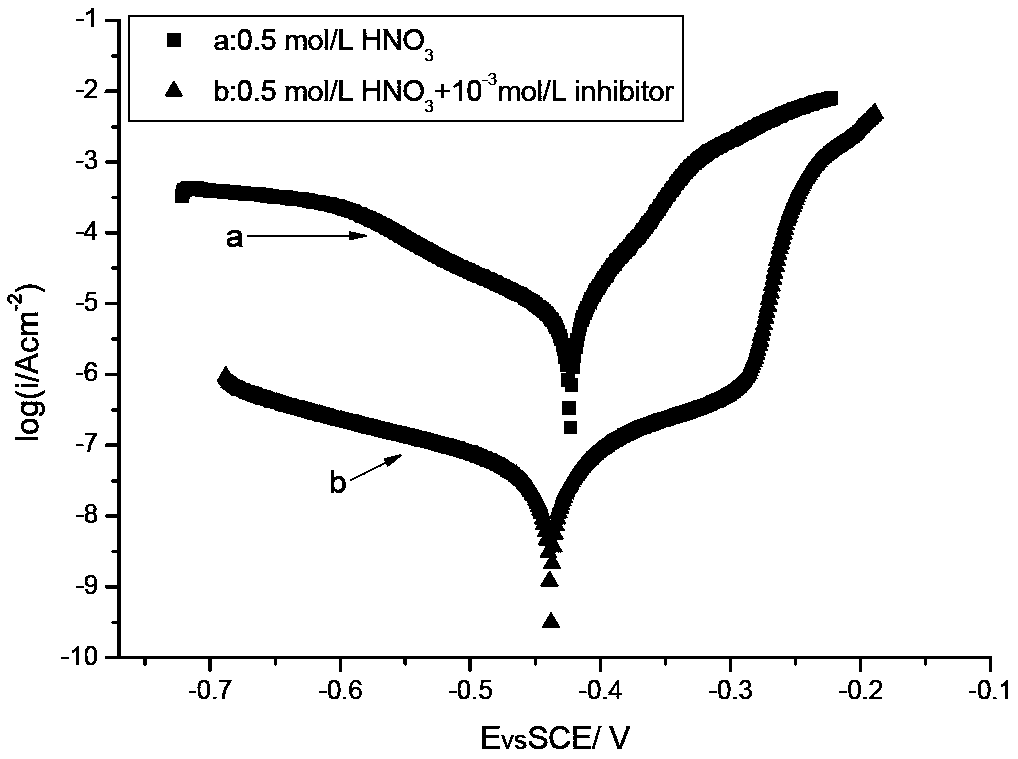

[0020] The acid solution in the pickling solution is dilute nitric acid, the concentration is 0.5mol / L, the amount of pickling solution is 1L, add 2-(4-chlorophenyl)-3-cyclopropyl-1-(1H-1,2, 4-triazol-1-yl)butan-2-ol 10 -3 mol / L, under the condition of 25°C, immerse the metal copper to be cleaned in the pickling solution for 10 days in the weight loss test; soak for 1 hour in the electrochemical test.

[0021] The highest corrosion inhibition efficiency obtained through the weight loss test is 88.7%, the electrochemical impedance spectroscopy test results show that the corrosion inhibition efficiency is 98.7%, the potentiodynamic polarization curve test results show that the corrosion inhibition efficiency is 99.7%, and the corrosion inhibition efficiency in the pickling treatment solution shown to be effective corrosion inhibitors.

Embodiment 2

[0023] The acid solution in the pickling solution is dilute nitric acid and dilute sulfuric acid, the concentration is 0.5mol / L respectively, the amount of pickling solution is 100L, add 2-(4-chlorophenyl)-3-cyclopropyl-1-(1H- The amount of 1,2,4-triazol-1-yl)butan-2-ol is 10 -3 mol / L, immerse the copper clad laminate to be cleaned in the pickling solution for 15 days at 25°C.

[0024] The highest corrosion inhibition efficiency obtained by the weight loss test is 90%, and the corrosion inhibitor in the pickling treatment solution is shown to be an efficient corrosion inhibitor.

Embodiment 3

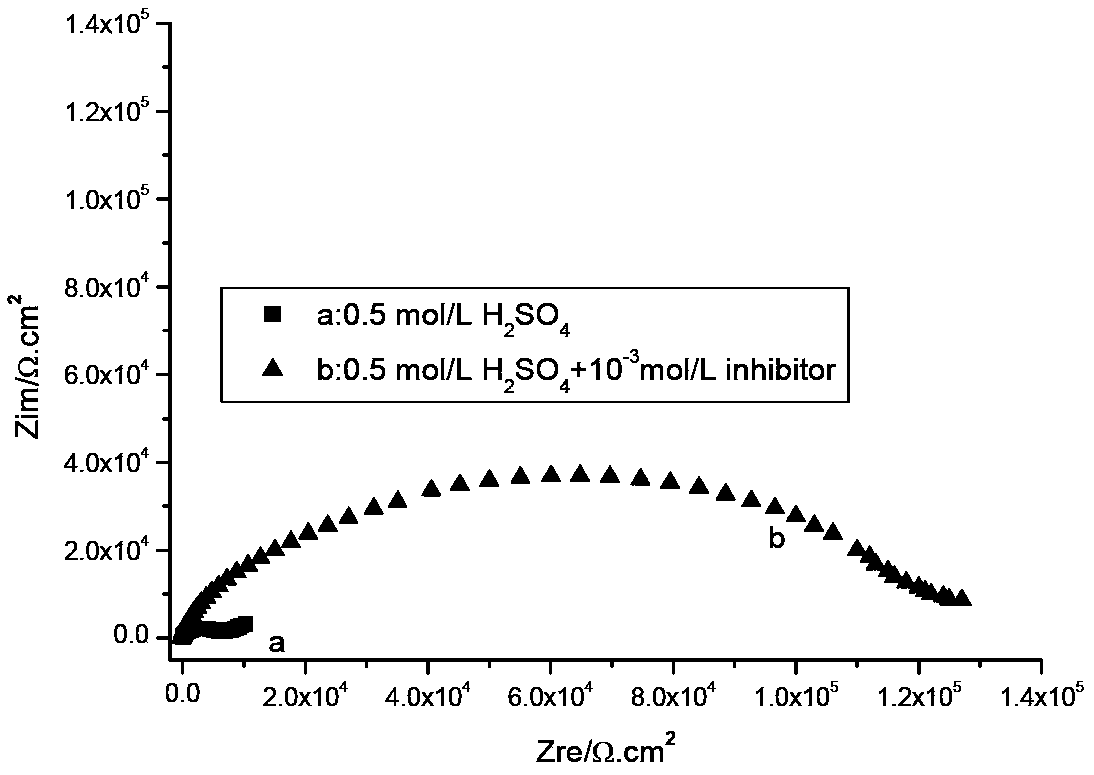

[0026] The acid liquid in the pickling liquid is dilute sulfuric acid, the concentration is 0.5mol / L, the amount of pickling liquid is 10L, add 2-(4-chlorophenyl)-3-cyclopropyl-1-(1H-1,2, The amount of 4-triazol-1-yl)butan-2-ol is 10 -3 mol / L, immerse the metal copper to be cleaned in the pickling solution for 20 days in the weight loss test at 15°C; soak for 2 hours in the electrochemical test.

[0027] The highest corrosion inhibition efficiency obtained by weight loss test is 82.1%, the electrochemical impedance spectroscopy test results show that the corrosion inhibition efficiency is 93.7%, the potentiodynamic polarization curve test results show that the corrosion inhibition efficiency is 84.1%, and the corrosion inhibition efficiency in the pickling treatment solution shown to be effective corrosion inhibitors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com