Hydrogen gas compressor seal fitting

A compressor and nitrogen sealing technology, which is applied to pump components, mechanical equipment, variable capacity pump components, etc., can solve the problems of hydrogen molecules being difficult to seal, and achieve the effects of low power consumption, simple operation and maintenance, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

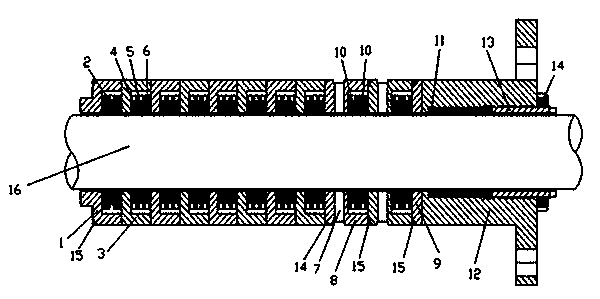

[0015] The present invention will be further described below in conjunction with accompanying drawing.

[0016] like figure 1 A sealing kit for a hydrogen compressor is shown, including a throttle ring (2), a stuffing box (3), a nitrogen seal chamber (7), an "O" ring (14), a stuffing box pressure plate (9), a stuffing pressure Cover (11), shaft seal ring (10), shaft seal compression bolt (12), shaft seal compression nut (13).

[0017] Install 1 set of throttle rings (2), 7 sets of stuffing boxes (3), packing pressing plates (9), 2 sets of nitrogen sealing chambers (7), and 2 sets of nitrogen stuffing boxes (8) on the stuffing box base (1) in sequence , Packing gland (12), multiple sets of shaft seal rings (11) are installed between the stuffing gland (12) and the piston rod (16), and then the shaft seal compression bolt (13) is installed, and the shaft seal compression nut is tightened (14).

[0018] A radial sealing ring (4), a tangential sealing ring (5) and a choke ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com