Silicon steel texture measuring method

A measurement method and texture technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as difficult to control corrosion time and thickness, small measurement range, prolong measurement time, etc., to achieve convenient and fast measurement, reliable and accurate results , the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

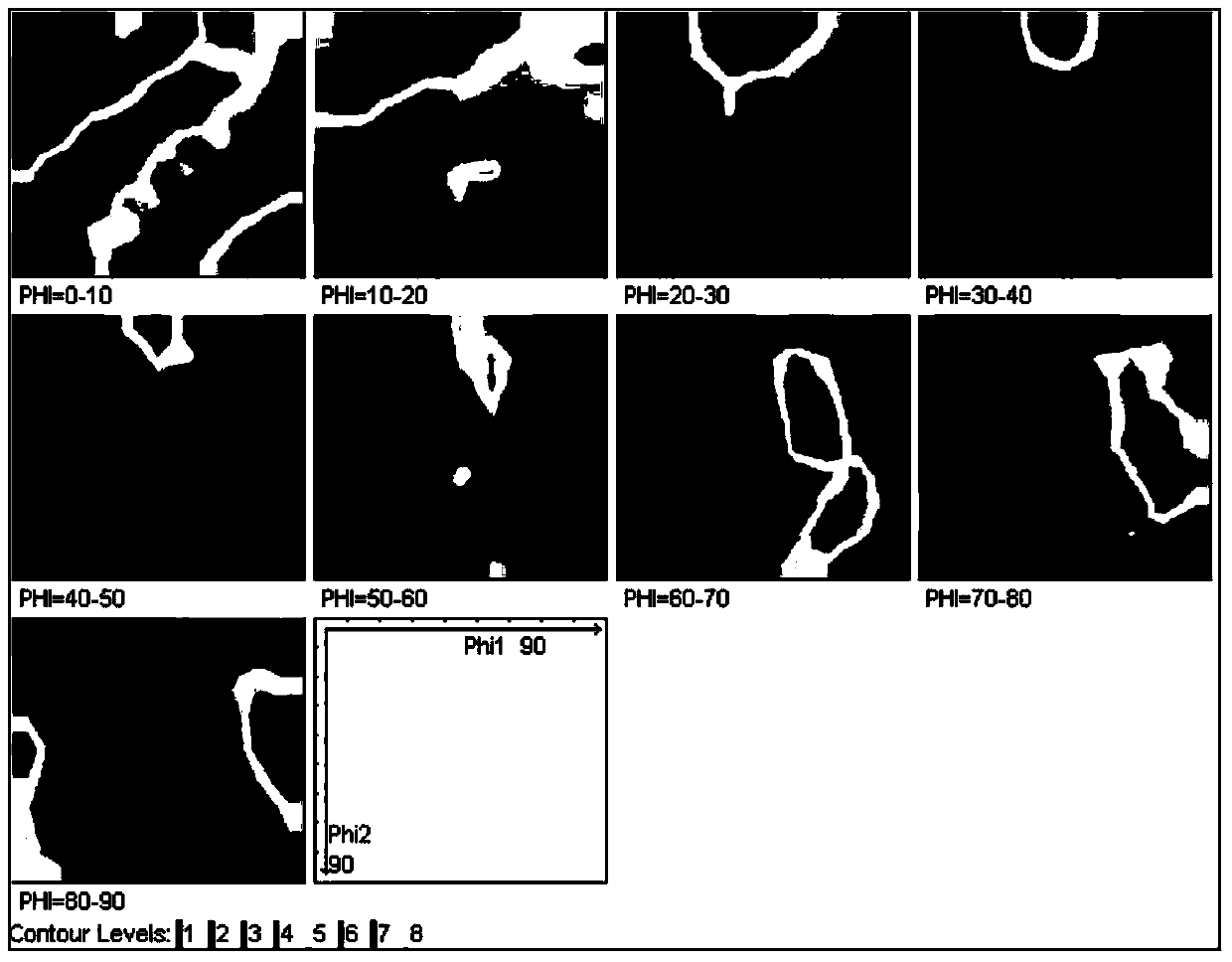

[0030] Taking the hot-rolled silicon steel sheet as an example, the method of measuring the texture along the thickness direction of the sheet is introduced. The specific steps are as follows:

[0031] A) EBSD analysis samples were prepared along the longitudinal section of the silicon steel hot-rolled plate through the following steps: sampling → inlaying → polishing (coarse grinding and fine grinding) → mechanical polishing, and finally electrolytic polishing to remove stress;

[0032] B) Use the EBSD equipment equipped with the scanning electron microscope to measure the orientation distribution diagram of the longitudinal section of the sample. The thickness ranges from the surface of the steel plate to the center of the thickness, and the orientation distribution from the surface of the hot-rolled silicon steel plate to the center of the thickness is as follows: figure 1 As shown; in order to ensure the accuracy of the measurement and reduce the error caused by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com