An element grain boundary segregation semi-quantitative method based on a scanning electron microscope

A technology of grain boundary segregation and scanning electron microscopy, which is applied in the direction of measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve the problems of inability to define grains, quantitative analysis, and low resolution, and achieve easy operation, The effect of simple characterization process and convenient sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

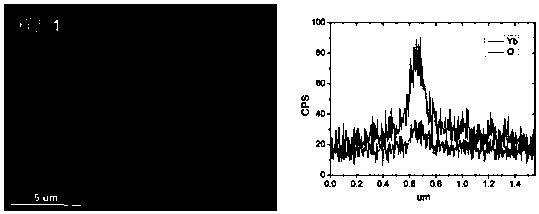

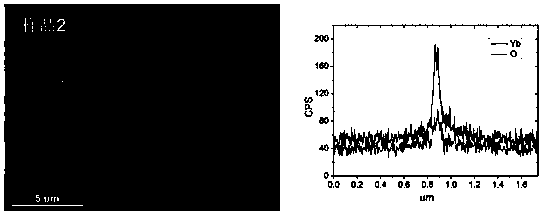

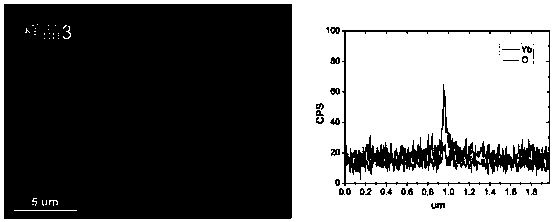

[0023] The filled-type skutterudite thermoelectric materials prepared by traditional fusion annealing combined with plasma sintering method SPS, according to the different annealing time, the samples with annealing time of 1 day, 3 days and 7 days were respectively named as sample 1, sample 2 and Sample 3, as a material sample.

[0024] In this embodiment, a semi-quantitative method for grain boundary segregation of elements based on scanning electron microscopy comprises the following steps:

[0025] a. Sample preparation: first cut the material sample into small pieces, then grind and polish the surface of the sample on diamond sandpaper with a particle size of 6 μm, 3 μm, 1 μm and 0.5 μm in turn, and finally polish it into a mirror surface, before putting it into the SEM sample chamber Perform plasma cleaning on the sample to remove the surface contamination of the material sample and obtain a clean sample;

[0026] b. Semi-quantitative analysis of the energy spectrum at t...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, especially in that:

[0056] A single crystal of quasi-skutterudite structure was prepared by flux growth method as a material sample. A scanning electron microscope-based semiquantitative method for elemental grain boundary segregation was employed. The method includes sample preparation and energy spectrum analysis at the grain boundary, according to the public The amount of segregation at the grain boundary is obtained, where the solid solution values of the segregation elements at the grain boundary and within the grain are defined respectively N r b is the bit density of the reference element, and the electron beam spot diameter d can be obtained by simulating the Monte Carlo electron trajectory with the software Casino 1 , and then according to the announcement The chemical breadth of segregated elements at grain boundaries can be obtained. The invention realizes semi-quantitative grain boundary seg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com