Rapid Quantitative Analysis Method of Anti-aging Agent in Rubber

A quantitative analysis and anti-aging agent technology, which is applied in the field of rubber and rubber formula analysis, can solve the problems of self-loss and low quantitative results, and achieve good results, convenient sample processing, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

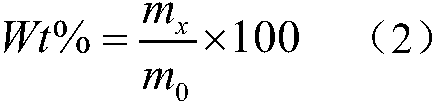

Method used

Image

Examples

Embodiment 1

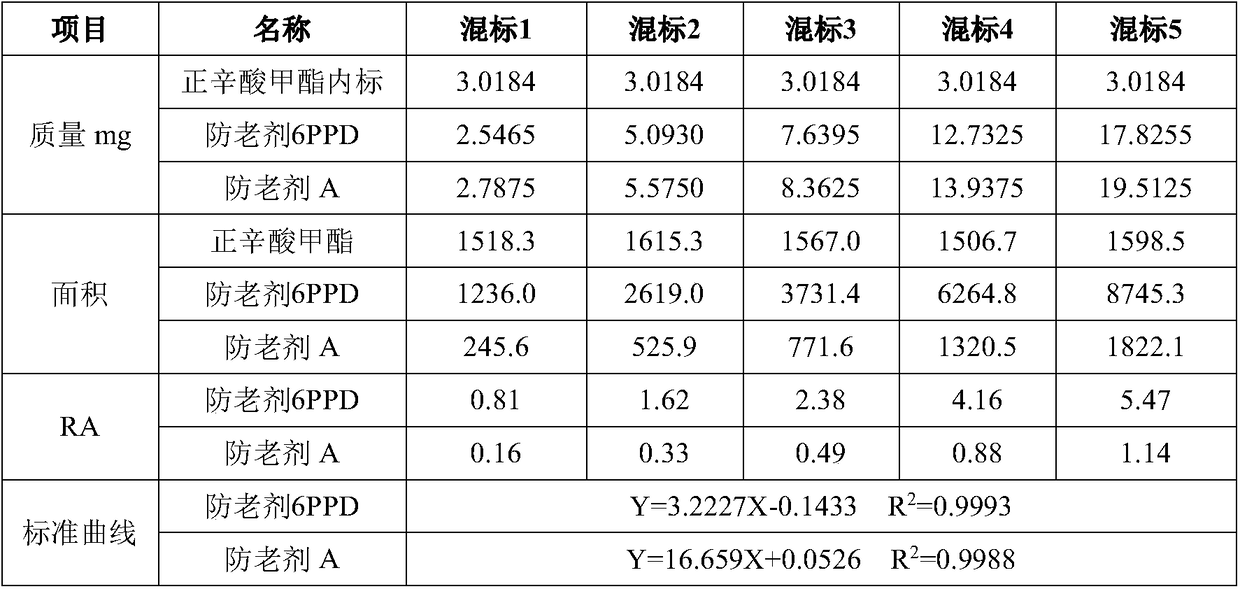

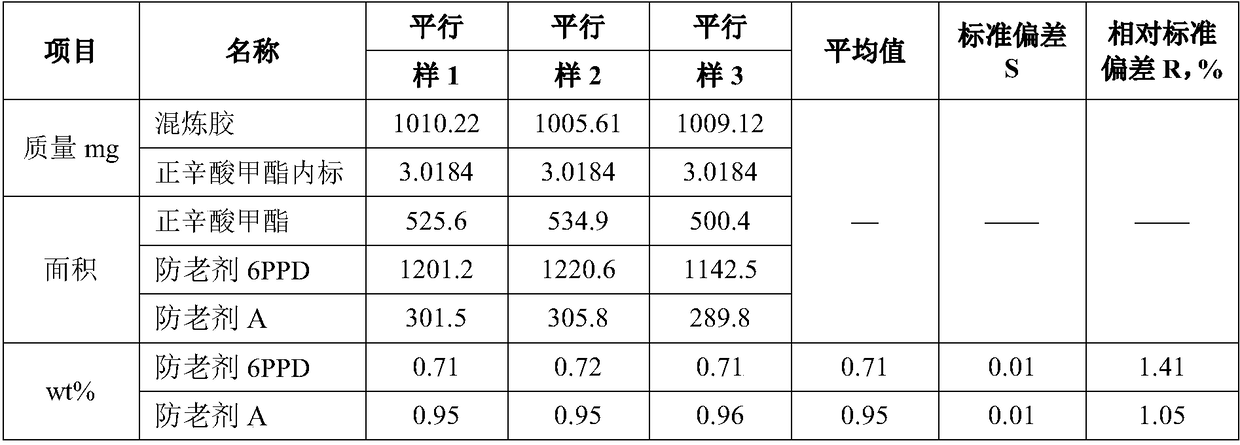

[0029] Example 1: Quantitative analysis of anti-aging agent in laboratory self-made 1# compound rubber and vulcanized rubber

[0030] The basic formula of the rubber compound is (parts by mass):

[0031] Component 1: natural rubber NR 100; carbon black N33045, silica 7000GR 40, stearic acid (industrial grade) 2.0, zinc oxide 3.5, silane coupling agent X50S 8.0, zinc stearate (laboratory self-made) 2.5, Pentaerythritol Stearate 1.0,

[0032] Component 2: Antiaging agent 6PPD 1.5, Antiaging agent A 2.0,

[0033] Component 3: Sulfur 1.8, vulcanization accelerator NS 1.5,

[0034] Preparation process: In a 1.6-liter Banbury mixer (manufactured by FARREL), add natural rubber NR and knead for 60s, then add stearic acid and zinc oxide and continue kneading for 40s, and finally add carbon black, white carbon black, silane coupling agent, zinc stearate, pentaerythritol stearate, knead to a temperature of 160°C, discharge the glue and take out the sheet, cool for later use, and obtai...

Embodiment 2

[0066] Example 2: Quantitative analysis of anti-aging agent in laboratory self-made 2# compound rubber and vulcanized rubber

[0067] The basic formula of the rubber compound is (parts by mass):

[0068] Component 1: natural rubber NR 100; carbon black N330 45, white carbon black 7000GR 40, stearic acid (industrial grade) 2.0, zinc oxide 3.5, silane coupling agent X50S 8.0, zinc stearate (laboratory self-made) 2.5 , Pentaerythritol Stearate 1.0,

[0069] Component 2: Antiaging agent 4010NA 2.5, Antiaging agent D 1.5,

[0070] Component 3: Sulfur 1.8, vulcanization accelerator NS 1.5,

[0071] Preparation process: In a 1.6-liter Banbury mixer (manufactured by FARREL), add natural rubber NR and knead for 60s, then add stearic acid and zinc oxide and continue kneading for 40s, and finally add carbon black, white carbon black, silane coupling agent, zinc stearate, pentaerythritol stearate, knead to a temperature of 160°C, discharge the glue and take out the sheet, cool for late...

Embodiment 3

[0091] Example 3: Quantitative analysis of anti-aging agent in the sidewall rubber of German Continental snow tire (205 / 55R16) (it has been determined that the rubber contains anti-aging agent 6PPD and anti-aging agent 4030 by other analysis means)

[0092] 3.1 Preparation of internal standard stock solution: Weigh 150.21 mg of methyl n-octanoate into a 50 mL volumetric flask, and dilute to volume with acetone.

[0093] 3.2 Preparation of mixed standard sample stock solution: Weigh 254.65mg of antiaging agent 6PPD and 246.59mg of antiaging agent 4030 into a 50mL volumetric flask, dissolve in acetone to volume.

[0094] 3.3 Preparation of standard series solutions: pipette 0.5mL, 1.0mL, 1.5mL, 2.5mL, and 3.5mL of standard sample stock solution into five 10mL volumetric flasks in sequence, add 1.0mL internal standard stock solution respectively, and dilute with acetone.

[0095] 3.4 Preparation of rubber extract: use MM400 mixed freeze grinder (manufactured by Retsch, Germany) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com