Heat-resistant seamless lapped aviation cable and preparation method thereof

A technology of high temperature resistance and wrapping, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of loose bonding and affecting the performance of wires, etc., and achieve stable and uniform tension, precise temperature control, and fast heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

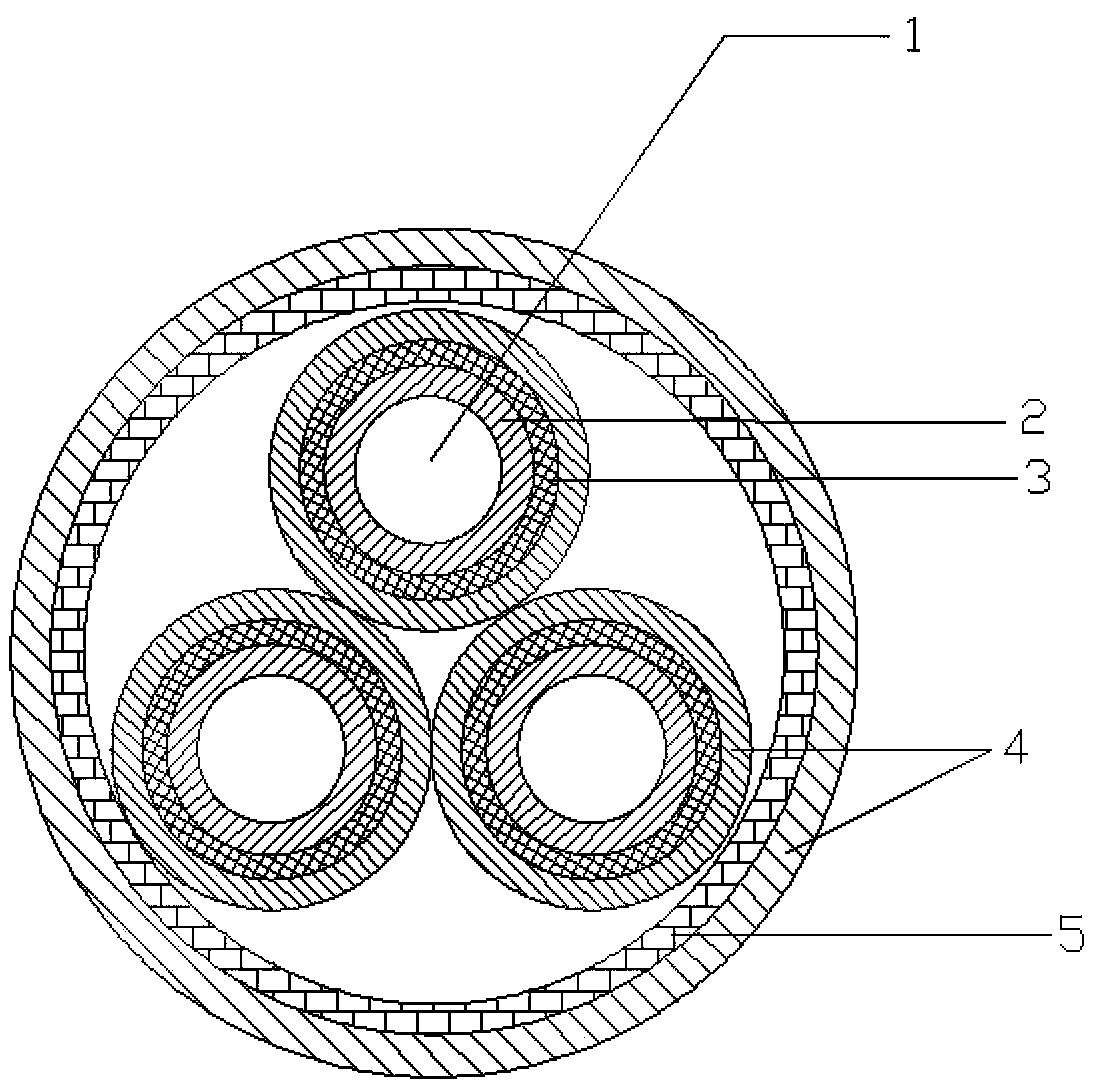

Image

Examples

Embodiment 1

[0033] Taking silver-plated copper conductor wire as an example, its preparation process is as follows:

[0034] (1) Insulation wrapping: the silver-plated copper conductor is the conductor core, and the polytetrafluoroethylene modified turning tape (Yangzhong Guyong Chemical Instrument Equipment Factory), polyimide film (Changshu Huaqiang Insulation Material Co., Ltd., FH type) and polytetrafluoroethylene raw material tape (Taixing Yongsheng Fluoroplastic Products Co., Ltd.) to wrap the conductor core. The thickness of the inner polytetrafluoroethylene modified turning tape is 0.01mm, the width is 60mm, the winding direction is to the right, the wrapping angle is 30°, and the covering rate is 55%; the thickness of the polyimide film in the middle layer is 0.05mm, The width is 50mm, the wrapping angle is 40°, the winding direction is left, and the covering rate is 50%; the thickness of the outer PTFE raw material tape is 0.5mm, the width is 30mm, the wrapping angle is 30°, and...

Embodiment 2

[0041] Taking silver-plated copper conductor wire as an example, its preparation process is as follows:

[0042](1) Insulation wrapping: the silver-plated copper conductor is the conductor core, and the polytetrafluoroethylene modified turning tape (Yangzhong Guyong Chemical Instrument Equipment Factory), polyimide film (Changshu Huaqiang Insulation Material Co., Ltd., FH type) and polytetrafluoroethylene raw material tape (Taixing Yongsheng Fluoroplastic Products Co., Ltd.) to wrap the conductor core. The thickness of the inner polytetrafluoroethylene modified turning tape is 0.05mm, the width is 8mm, the winding direction is to the right, the wrapping angle is 45°, and the covering rate is 52%; the thickness of the polyimide film in the middle layer is 0.03mm, The width is 3mm, the wrapping angle is 50°, the winding direction is left, and the covering rate is 52%; the thickness of the outer PTFE raw material tape is 0.02mm, the width is 6mm, the wrapping angle is 45°, and th...

Embodiment 3

[0048] Taking the silver-plated copper conductor cable as an example, the preparation process is as follows:

[0049] (1) Insulation wrapping: the silver-plated copper conductor is the conductor core, and the polytetrafluoroethylene modified turning tape (Yangzhong Guyong Chemical Instrument Equipment Factory), polyimide film (Changshu Huaqiang Insulation Material Co., Ltd., FH type) and polytetrafluoroethylene raw material tape (Taixing Yongsheng Fluoroplastic Products Co., Ltd.) to wrap the conductor core. The thickness of the inner polytetrafluoroethylene modified turning tape is 0.2mm, the width is 22mm, the winding direction is to the right, the wrapping angle is 60°, and the covering rate is 60%; the thickness of the polyimide film in the middle layer is 0.04mm, The width is 15mm, the wrapping angle is 60°, the winding direction is left, and the covering rate is 58%; the thickness of the outer PTFE raw material tape is 0.1mm, the width is 30mm, the wrapping angle is 60°,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com