Light-reflecting coating, method for preparing same and photovoltaic module using same

A reflective coating and photovoltaic module technology, which is applied in the manufacture of electrical components, semiconductor devices, final products, etc., can solve the problems of solar module efficiency improvement, poor reflection effect, etc., achieve good reflection, increase effective light, and improve reflection performance effect

Active Publication Date: 2013-11-13

CHANGSHU CANADIAN SOLAR ELECTRIC POWER TECHCO +2

View PDF2 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In solar modules, in addition to absorbing sunlight to excite electron-hole pairs to generate photogenerated carriers, the improvement of photoelectric conversion efficiency also depends on the reflection and scattering of solar panels and backplanes, while the reflection of conventional backplanes and ribbons The effect is very poor, almost does not help the efficiency of solar modules

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0039] The preparation method of reflective coating of the present invention comprises the following steps:

[0040] First, add the dispersant, glass microspheres and titanium dioxide to the high-speed mixer and mix evenly;

[0041] Then, add the resin, xylene, solvent, leveling agent, defoamer, and antioxidant in sequence, and at the same time, stir until a uniform solution is obtained.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

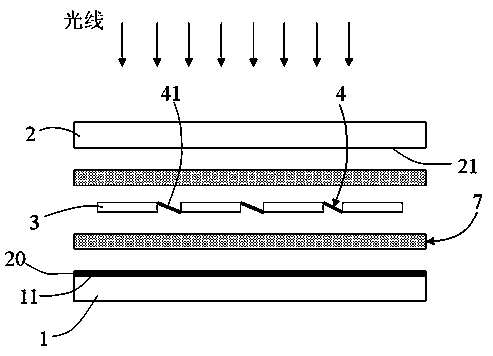

The invention provides a light-reflecting coating used for a photovoltaic module. The light-reflecting coating comprises, by weight part ratio, 40-60 parts of resin, 5-10 parts of solvent, 10-30 parts of titanium dioxide, 20-40 parts of glass beads and 5-15 parts of xylene. The light-reflecting coating is applied to a backboard of the photovoltaic module and the surface of a bus bar so as to increase effective light reflected from the bus bar and the surface of the backboard, the light can be further reflected or scattered to a battery piece, and therefore photoelectric conversion efficiency of the assembly is greatly improved. Because the titanium dioxide is added, the light-reflecting coating has excellent reflection effect and uvioresistant effect. The glass beads ensure that the coating has excellent self-cleaning and light reflecting performance.

Description

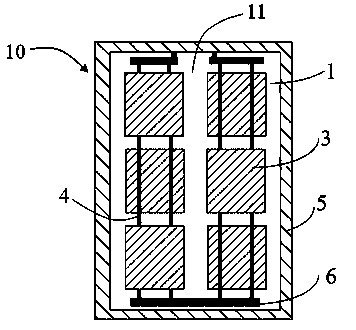

technical field [0001] The invention relates to the field of photovoltaics, in particular to a photovoltaic module with a reflective coating. Background technique [0002] Reflective and scattering coatings are very suitable for the solar processing industry due to their excellent reflection and scattering effects, especially for materials such as solder strips and backplanes. [0003] In solar modules, in addition to absorbing sunlight to excite electron-hole pairs to generate photogenerated carriers, the improvement of photoelectric conversion efficiency also depends on the reflection and scattering of solar panels and backplanes, while the reflection of conventional backplanes and ribbons The effect is very poor, and it hardly helps to improve the efficiency of solar modules. [0004] In view of this, it is necessary to provide a new reflective coating for photovoltaic modules to solve the above problems. Contents of the invention [0005] The technical problem to be ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L31/0216H01L31/18

CPCY02P70/50

Inventor 刘国丽许涛陈道远

Owner CHANGSHU CANADIAN SOLAR ELECTRIC POWER TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com