Series-parallel vibrating screen with five degrees of freedom

A technology of vibrating screen and degree of freedom, which is applied in the direction of filter screen, solid separation, grille, etc., which can solve the problems of poor adaptability of screening objects, poor effect of sieving, and low dispersion of materials, so as to achieve convenient operation and maintenance, The equipment occupies a small space, and the quality is stable and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand and understand, the present invention will be further described below with reference to specific embodiments and illustrations.

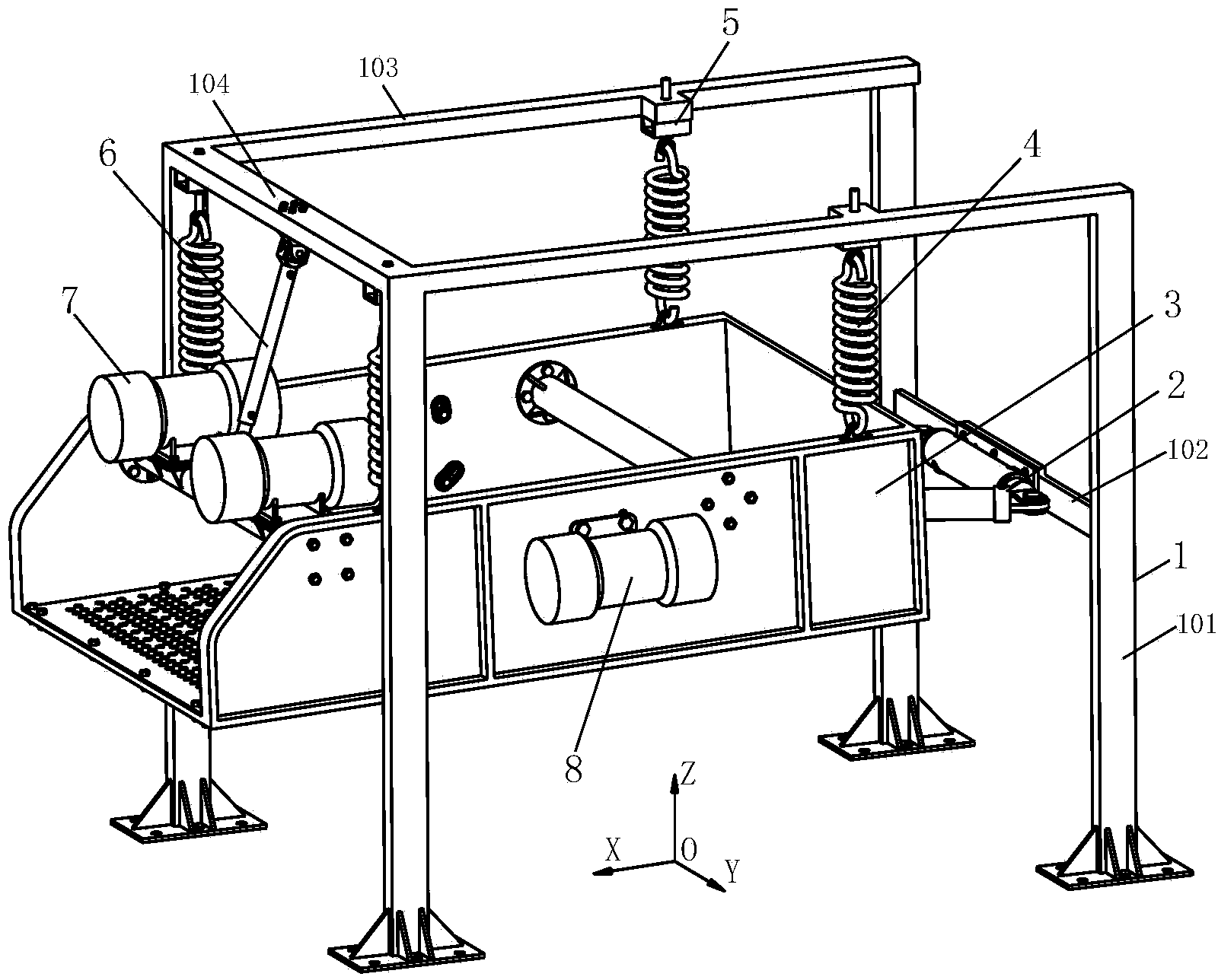

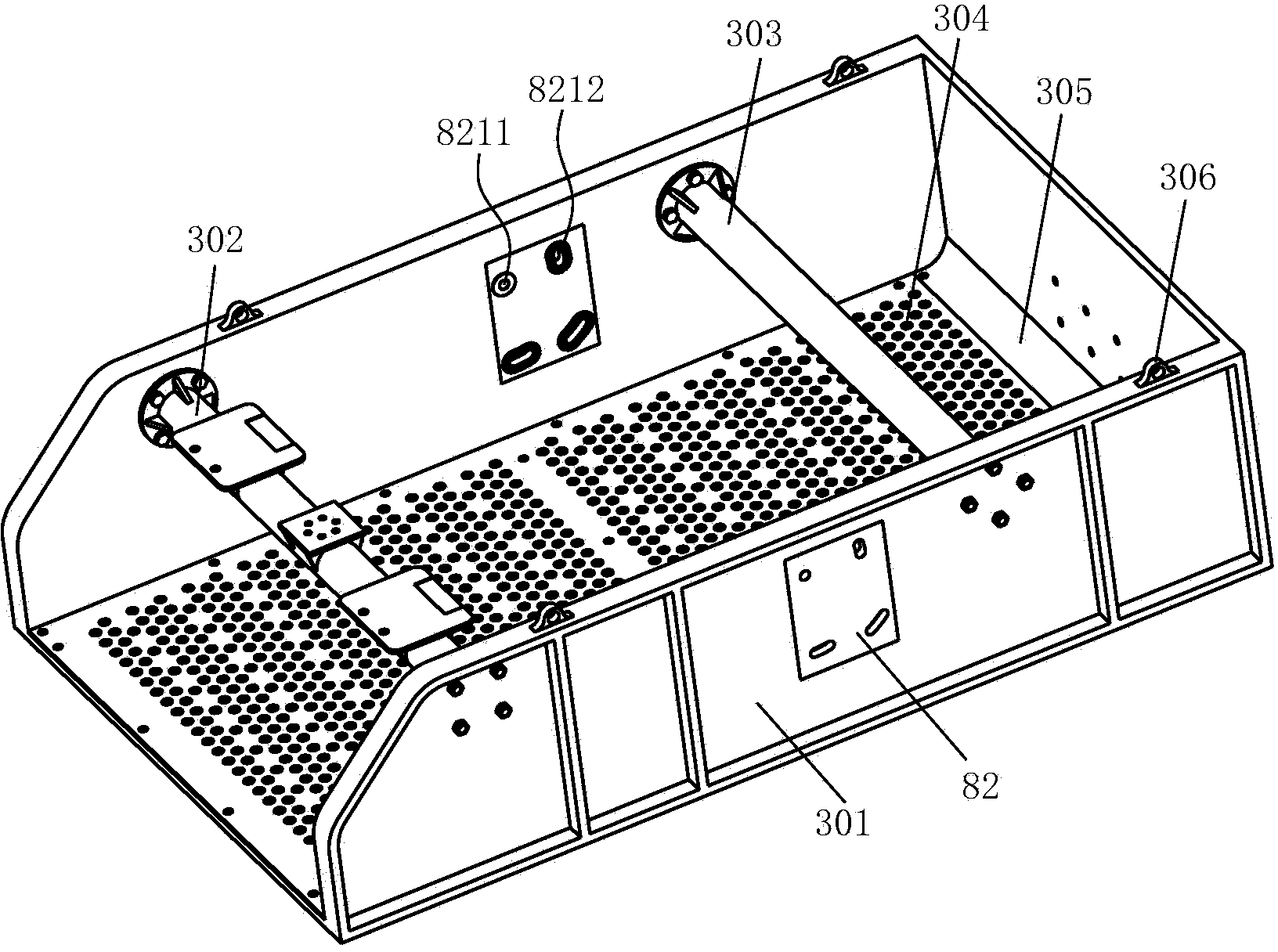

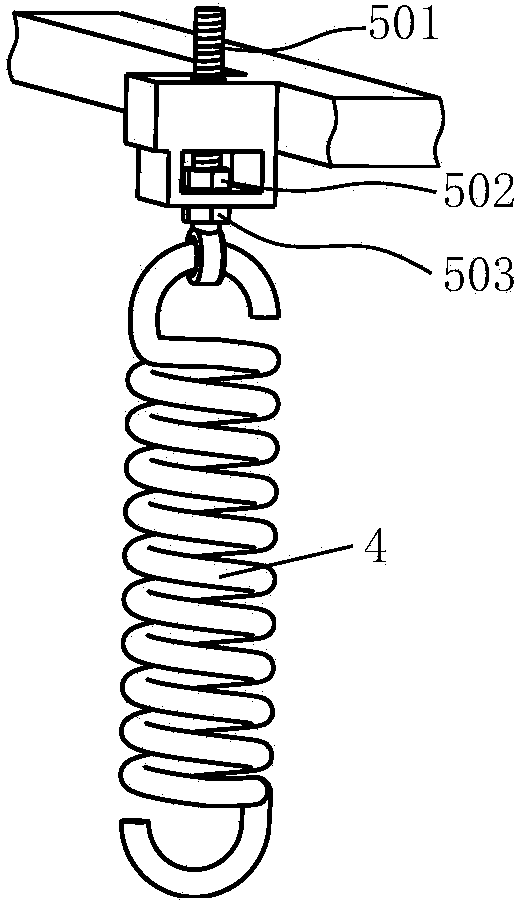

[0024] like figure 1 and figure 2As shown, a five-degree-of-freedom hybrid vibrating screen includes a support frame 1, a parallel vibration excitation device 2, a screen body 3, a spring 4, an inclination angle adjuster 5, a median vibration exciter 8, a screen tail exciter 7 and Tail balance chain 6. The support frame 1 includes a column 101, a first bearing beam 102, a top beam 103, and a tail bearing beam 104, and the bottom of the column 101 is provided with anchor bolt holes. The first bearing beam 102 and the top beam 103 Both are fixedly connected with the upright column 101, and the tail bearing beam 104 is fixedly connected with the top beam 103; the parallel excitation device 2 is located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com