Method for preparing KNbWO6.H2O

A technology of niobium tungstate and potassium niobium tungstate, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., to achieve low reaction temperature, improved product performance, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1.0g Nb 2 o 5 Add 5.0 g of KOH to 60 ml of deionized water, and conduct a hydrothermal treatment at 180° C. for 2 days. Get 2.4ml hydrothermal reaction product in the upper layer [Nb 6 o 19 ] 8- solution (ICP test the Nb in the solution 5+ Concentration is 0.1116mol / L), then add 20ml octanol, according to the molar ratio Nb 5+ :W 6+ =1:2.5 ratio by adding 0.1673g H 2 WO 4 , and then use dilute hydrochloric acid to adjust the pH of the solution to 7.2, put it into a 40ml reaction kettle, and conduct hydrothermal treatment at 220°C for 2 days. The obtained product was washed by centrifugation with deionized water and dried.

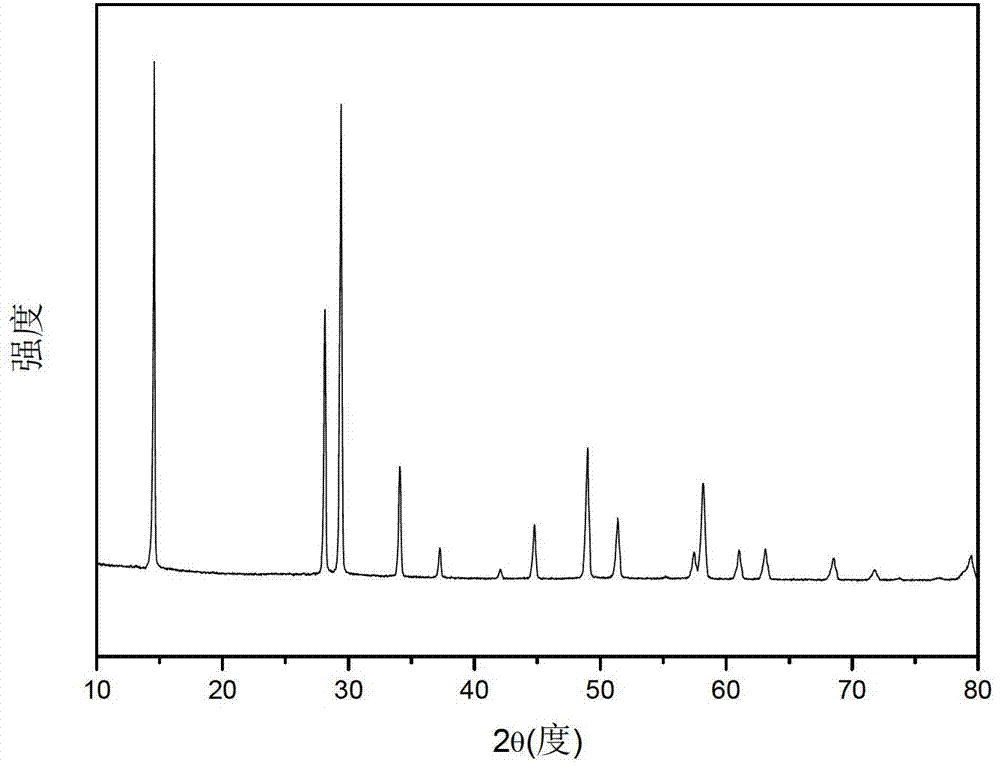

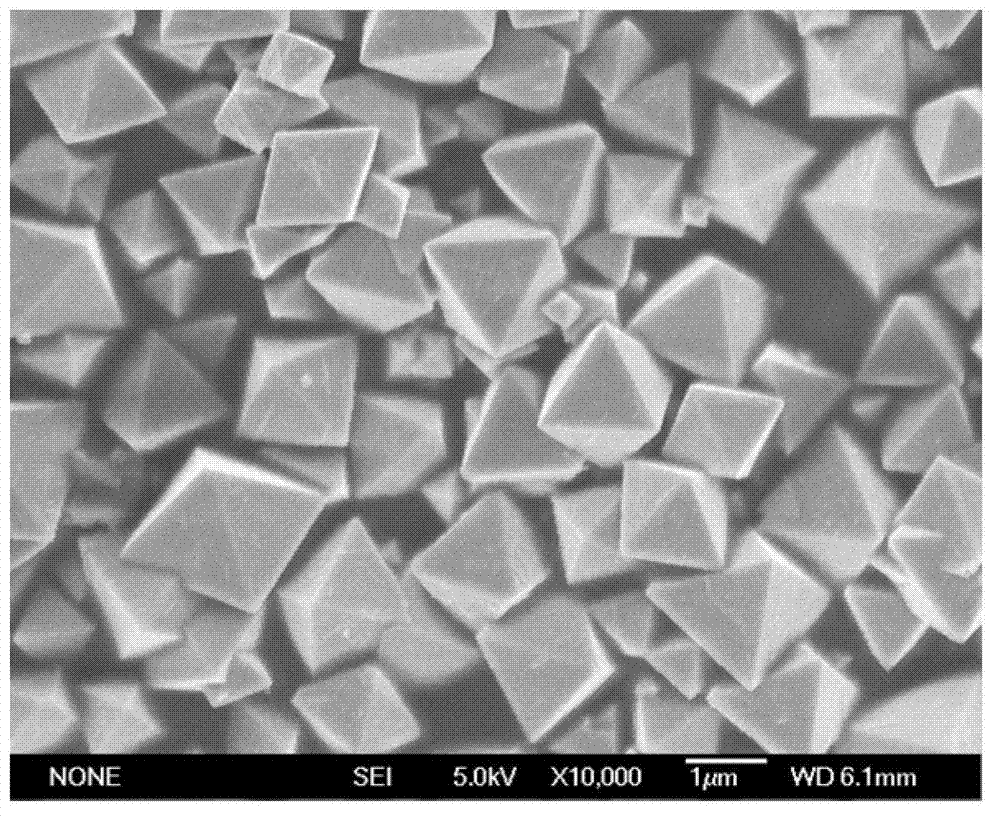

[0023] This embodiment is the best embodiment. Figure 1 ~ Figure 2 The obtained KNbWO is given respectively 6 ·H 2 XRD and SEM pictures of O.

Embodiment 2

[0025] 1.0g Nb 2 o 5 Add 5.0 g of KOH to 60 ml of deionized water, and conduct a hydrothermal treatment at 180° C. for 2 days. Get 2.4ml hydrothermal reaction product in the upper layer [Nb 6 o 19 ] 8- solution (ICP test the Nb in the solution 5+ Concentration is 0.1116mol / L), then add 20ml octanol, according to the molar ratio Nb 5+ :W 6+ =1:2.5 ratio by adding 0.1673g H 2 WO 4 , and then use dilute hydrochloric acid to adjust the pH of the solution to 7.2, put it into a 40ml reaction kettle, and conduct hydrothermal treatment at 220°C for 1 day. The obtained product was washed by centrifugation with deionized water and dried.

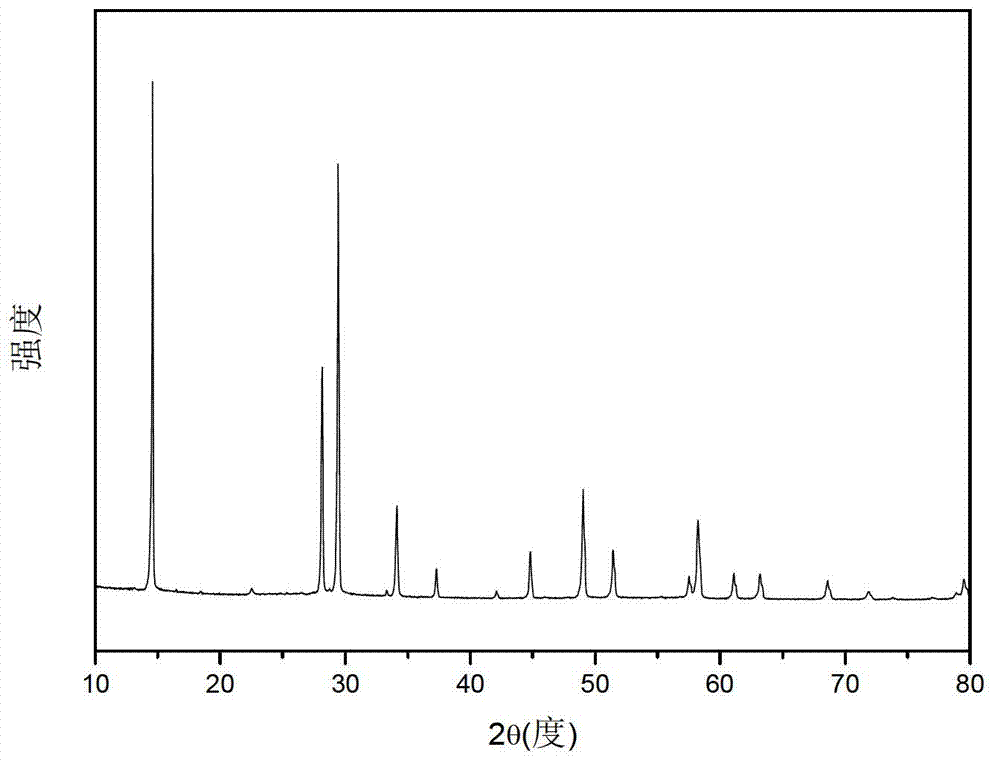

[0026] Compared with Example 1, when the reaction time was changed to 1 day, the morphology of the prepared product had no obvious change, and there was an extremely weak miscellaneous peak at 22° in the XRD spectrum observation spectrum.

Embodiment 3

[0028] 1.0g Nb 2 o 5Add 5.0 g of KOH to 60 ml of deionized water, and conduct a hydrothermal treatment at 180° C. for 2 days. Get 2.4ml hydrothermal reaction product in the upper layer [Nb 6 o 19 ] 8- solution (ICP test the Nb in the solution 5+ Concentration is 0.1116mol / L), then add 20ml octanol, according to the molar ratio Nb 5+ :W 6+ =1:2.5 ratio by adding 0.1673g H 2 WO 4 , and then use dilute hydrochloric acid to adjust the pH of the solution to 7.2, put it into a 40ml reaction kettle, and conduct hydrothermal treatment at 220°C for 5 days. The obtained product was washed by centrifugation with deionized water and dried.

[0029] Compared with Example 1, when the reaction time was extended to 5 days, the morphology of the obtained product did not change significantly, and no miscellaneous peaks were found in the XRD spectrum, but the intensity of the diffraction peak was slightly stronger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com