Preparation method of general intermediate ECPPA of ACEI (angiotensin converting enzyme inhibitor) medicines

A technology of intermediates and puli, applied in the field of preparation of pharmaceutical intermediates, can solve the problem of high cost of precious metal catalysts, and achieve the effects of improving yield, reducing costs and reducing separation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

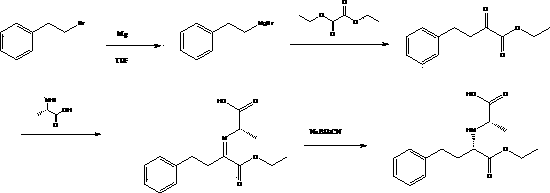

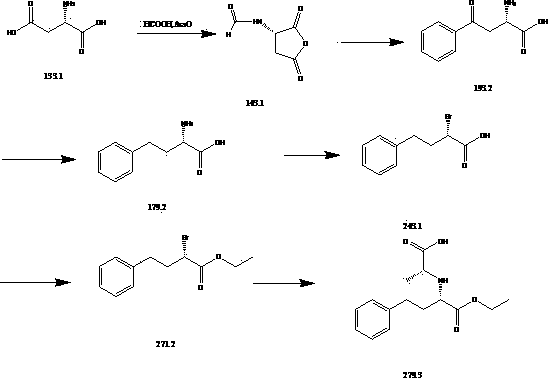

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the universal intermediate ECPPA of the pril class medicine of the present invention, the steps are as follows:

[0031]

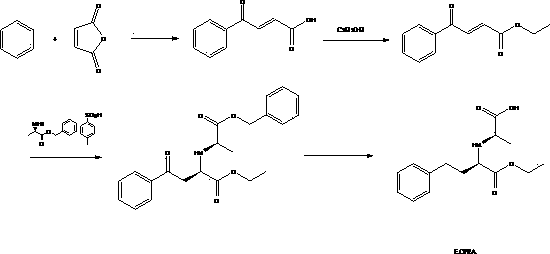

[0032] (1) Synthesis of benzoyl acrylic acid

[0033] Mix benzene and maleic anhydride, the dosage ratio of benzene and maleic anhydride is 800g: 135-143g, stir to dissolve;

[0034] Slowly add aluminum trichloride, the dosage ratio of benzene to aluminum trichloride is 800g: 555-605g, heat up and reflux for 55-65 minutes, and cool down to room temperature;

[0035] Slowly pour the reaction solution into a mixture of concentrated hydrochloric acid and crushed ice. The ratio of concentrated hydrochloric acid to crushed ice is 1-3 liters: 3kg, and the ratio of benzene to the mixture is 800g: 555-605ml; filter and dry to obtain a brown solid Granules, yield 98%, mp: 90~93℃, HPLC≥95%;

[0036] (2) Synthesis of ethyl benzoyl acrylate

[0037] Mix the benzoyl acrylic acid, ethanol, and boron trifluoride etherate complex syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com