Method for preparing biodiesel by utilizing oil plant

A technology of biodiesel and plants, which is applied in the direction of biofuel, fat oil/fat production, petroleum industry, etc., can solve the problems that the yield cannot be further improved, and the reaction catalyst is difficult to recycle, so as to avoid low reaction yield and promote continuous positive To progress and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0038] The biodiesel described in the present embodiment utilizes Xanthos sorbifolium seed kernel as raw material and is prepared by the following method:

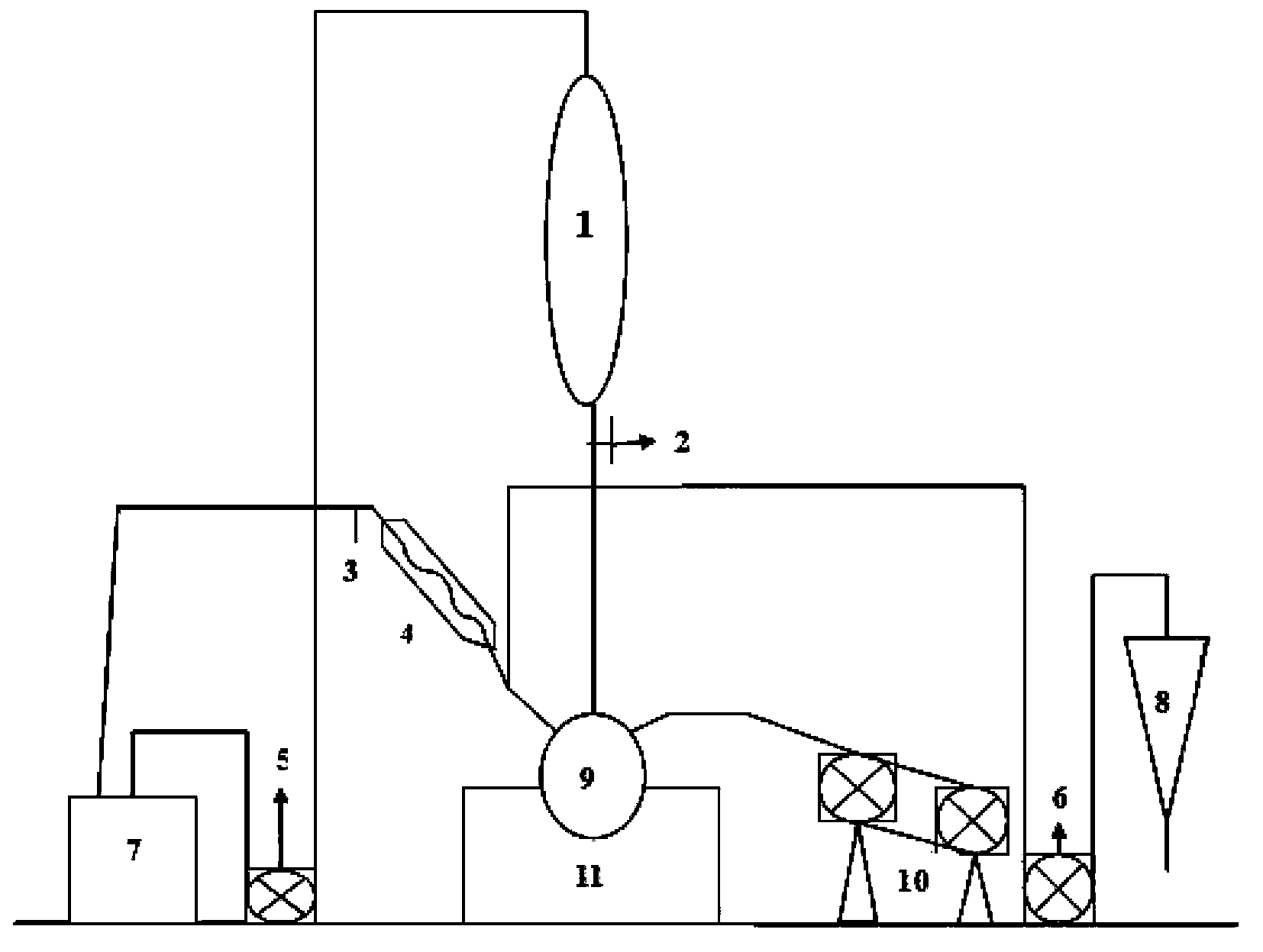

[0039] (1) Grind the radix sorbifolium seed kernels, pass through a 40-mesh sieve, and dry at 120°C, wrap 10g of the powder with degreasing filter paper and place it in the extraction cylinder 1 for later use;

[0040] (2) Add the activated carbon-supported KOH solid base catalyst into the reaction bottle 9 through the conveyor belt 10. The amount of the catalyst is 0.65 g. The two-liquid phase mixed solvent includes 20 g of n-hexane and 1 g of methanol, and is placed in the solvent bottle 7. And through the first peristaltic pump 5, the two-liquid-phase mixed solvent of n-hexane and methanol is pumped into the extraction cylinder 1 for extraction, and the temperature is controlled at 60°C to carry out the transesterification reaction;

[0041] (3) When the reaction solution after extraction turns yellow, add a two-liquid-...

Embodiment 1-2

[0047] The type and amount of oil-containing plants in the extraction process described in this embodiment are the same as in Example 1-1, and the type and content of the catalyst used are also the same as in Example 1-1. The only difference is that when the extraction begins, the The two-liquid-phase mixed solvent composed of 23g of n-hexane and 67g of methanol was directly added into the solvent bottle for reflux extraction operation, and the reaction temperature was controlled at 60°C throughout the process. In this embodiment, a total of 4.02 g of crude biodiesel was obtained, and the extraction rate of the crude biodiesel was 71.42%.

Embodiment 1-3

[0049] The type and amount of oil-containing plants in the extraction method described in this example, as well as the type and amount of the selected catalyst, the type and amount of the two-liquid phase mixed solvent and the addition method are the same as in Example 1-1, the only difference is that During the reaction process, the reaction temperatures of steps (2), (3) and (4) were respectively controlled at 40, 50 and 60° C. for reflux extraction. In this embodiment, a total of 5.47 g of crude biodiesel was obtained, and the extraction rate of the crude biodiesel was 97.31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com