Patching method for furnace lining of revolving furnace steel tapping hole part

A furnace lining repair and tapping hole technology, which is applied in the manufacture of converters, etc., can solve the problems of inaccurate repair positions and short use time of furnace materials, and achieve the effects of improving corrosion resistance, fast sintering speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

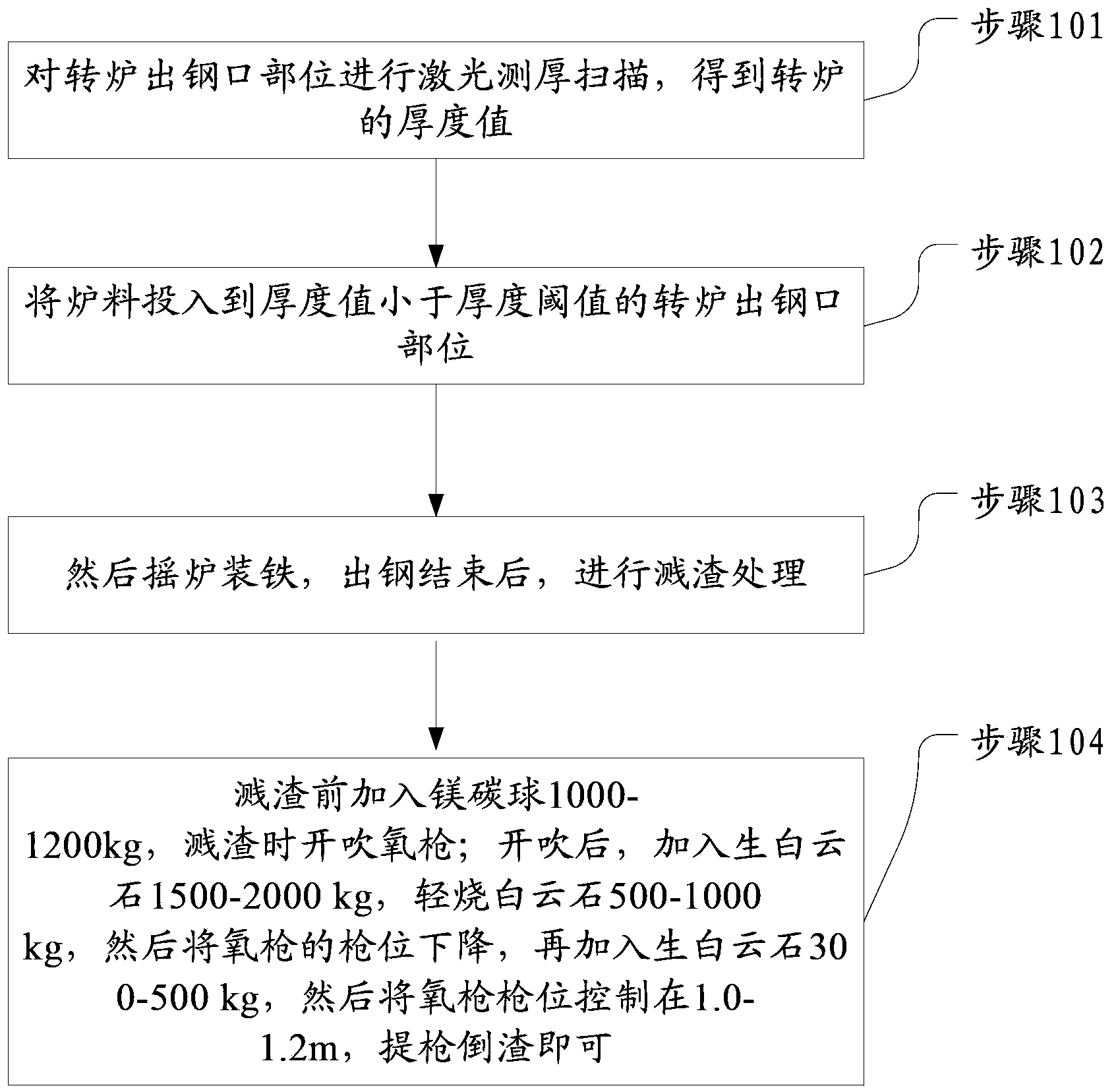

[0029] The embodiment of the present invention provides a method for repairing the lining of the tapping hole of a converter. For smelting 132B03812 heats, the production organization notifies that there is 10 minutes between pouring times, and the tapping hole can be arranged for maintenance. The team leader in front of the furnace organizes personnel to use environmentally friendly high-strength quick repair materials to repair the position directly above the tapping hole and the joint between the furnace cap and the furnace body after the furnace, including the following steps:

[0030] Step 101: performing laser thickness measurement and scanning on the tap hole of the converter to obtain the thickness value of the converter;

[0031] Step 102: Putting the charge into the tap hole of the converter whose thickness is less than 300 mm, it takes 5 minutes, wherein the components of the charge and their proportioning relationship are as follows:

[0032] Magnesia 50kg, graphit...

Embodiment 2

[0041] The embodiment of the present invention provides a method for repairing the lining of the tapping hole of a converter. The production organization notifies that there is a 10-minute gap between pouring times, and the tapping hole can be arranged for maintenance. The team leader in front of the furnace organizes personnel to use environmentally friendly high-strength quick repair materials to repair the position directly above the tapping hole and the joint between the furnace cap and the furnace body after the furnace, including the following steps:

[0042] Step 201: performing laser thickness measurement and scanning on the tap hole of the converter to obtain the thickness value of the converter;

[0043] Step 202: Putting the charge into the converter taphole with a thickness less than 300mm, which takes 5 minutes, wherein the components of the charge and their proportioning relationship are as follows in weight percentage:

[0044] Fused magnesia 50kg, flake graphit...

Embodiment 3

[0049] The embodiment of the present invention provides a method for repairing the lining of the tapping hole of a converter. The production organization notifies that there is a 10-minute gap between pouring times, and the tapping hole can be arranged for maintenance. The team leader in front of the furnace organizes personnel to use environmentally friendly high-strength quick repair materials to repair the position directly above the tapping hole and the joint between the furnace cap and the furnace body after the furnace, including the following steps:

[0050] Step 301: performing laser thickness measurement and scanning on the tap hole of the converter to obtain the thickness value of the converter;

[0051] Step 302: put the charge into the converter taphole with the thickness less than 300mm, which takes 5 minutes, wherein, the components of the charge and their proportioning relationship are as follows by weight percentage:

[0052] Fused magnesia 40kg, flake graphite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com