Construction method using glass fiber reinforced plastics as inner cavity protective materials for steel and concrete chimney

A technology of protective materials and construction methods, applied in the field of flue gas emission, can solve the problems affecting the anti-corrosion effect and service life, air bubbles, lack of glue, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

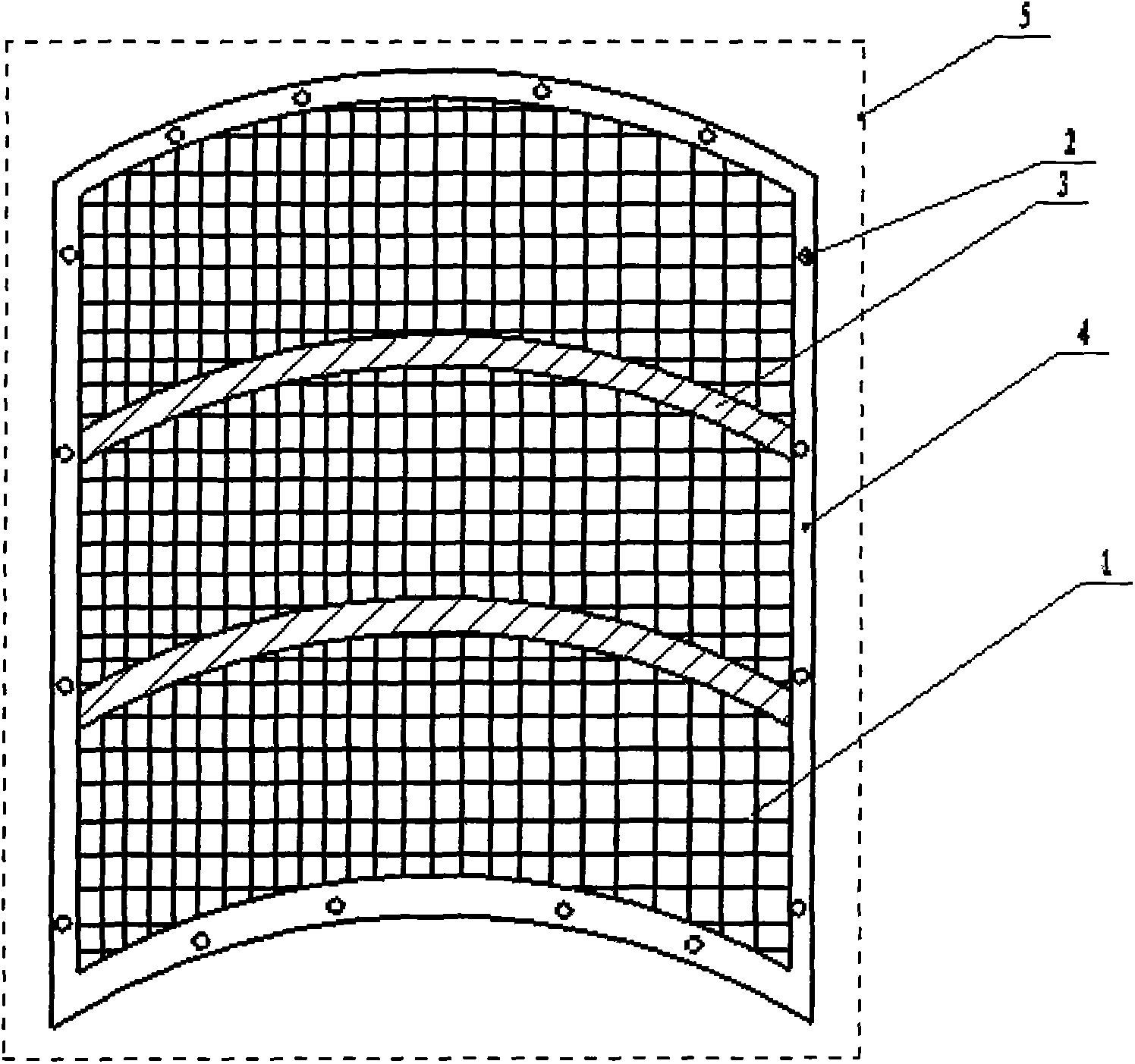

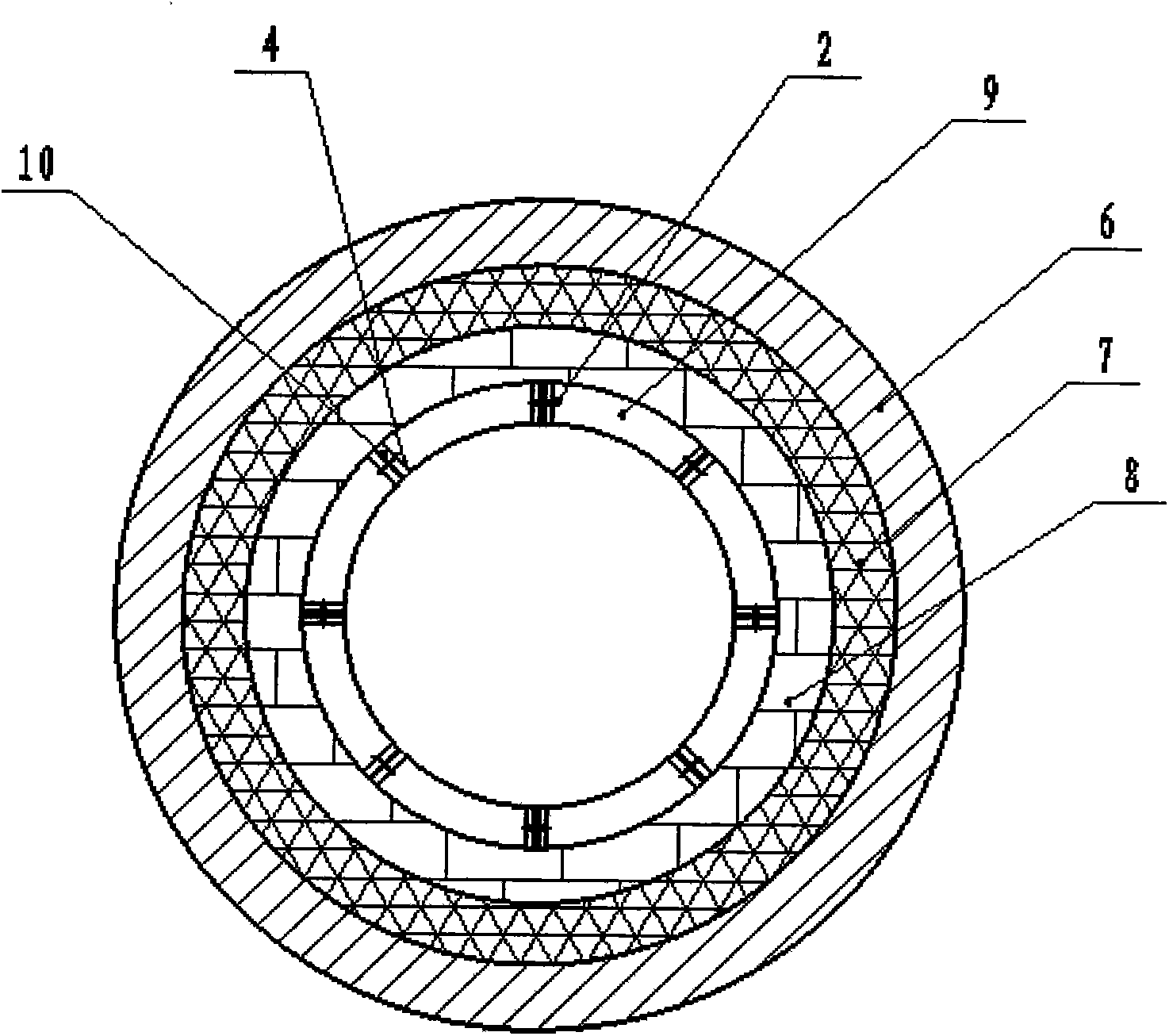

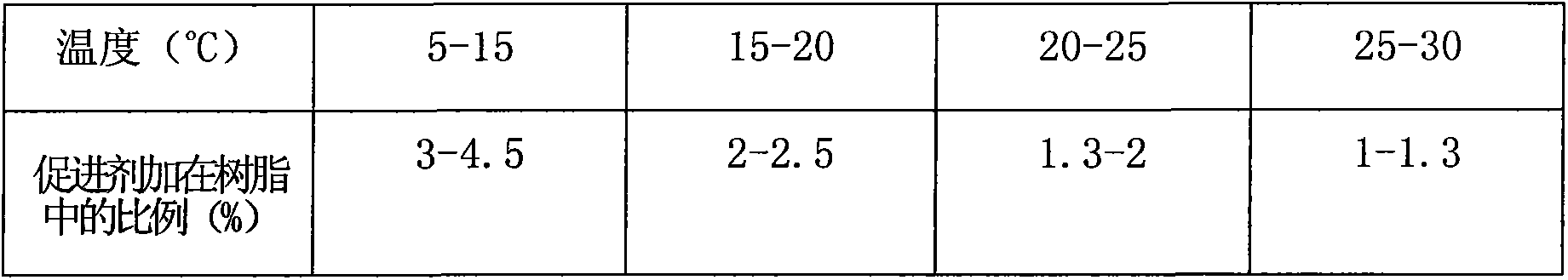

[0018] like figure 1 As shown, a construction method using glass fiber reinforced plastics as a protective material for the inner cavity of a steel-concrete chimney. First, a mold 9 with the same shape as the steel-concrete chimney and a slightly smaller diameter is made. The mold 9 is composed of at least one single-piece mold 5. 5 Brush or spray the gel coat with a thickness of 0.3-0.4mm on the outer surface first, then paste the FRP composite reinforced layer 8, assemble it in the chimney 6, and then inject it between the FRP composite reinforced layer 8 and the inner surface of the chimney 6 Resin mortar 7, finally pull out mold 9. After pasting the fiberglass composite reinforced layer 8 on the outer surface of the single-piece mold 5 , inject the resin mortar 7 while assembling in the chimney 6 . The mold 9 is composed of at least one single-piece mold 5, and the single-piece mold 5 includes a glass fiber reinforced plastic plate 1 and a keel 3. The said keel 3 is curve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal deformation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com