Dish-shaped rubber quasi-zero stiffness vibration isolator

A quasi-zero stiffness, vibration isolator technology, applied in non-rotational vibration suppression and other directions, can solve problems such as insufficient compact structure, small bearing capacity, and inability to meet a wide range of applications, achieving light weight, large bearing capacity, and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

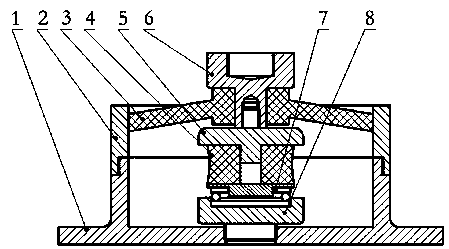

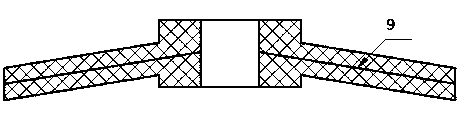

[0051] like Figure 1 to Figure 3 As shown, in Embodiment 1, a butterfly-shaped rubber quasi-zero stiffness vibration isolator includes a base 1, an upper cover 2 and a bearing joint 6, the inner wall of the upper cover 2 is connected with a butterfly-shaped rubber 3, and the butterfly-shaped rubber The rubber 3 is fixedly connected with the bearing joint 6 and the upper cover 2 to form an elastic element with negative stiffness. The butterfly rubber 3 is provided with a reinforcing rib 9, and the bearing joint 6 is connected with the positive The rigid axial rubber 4 is connected, and the axial rubber 4 is connected to the base 1 through an adjustment sleeve 8 . The butterfly rubber 3 is connected as a whole with the upper cover 2 and the bearing joint 6 by vulcanization. The gland 5 is screwed to the bearing joint 6 , and the axial rubber 4 supports the gland 5 in a hole-fitting manner. A thrust ball bearing 7 is also provided between the adjustment sleeve 8 and the axial ...

Embodiment 2

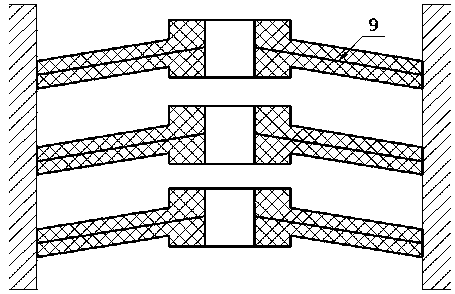

[0053]The difference between embodiment 2 and embodiment 1 is that in order to provide greater negative stiffness in a limited space, the number of disc rubber 3 in the present invention can be multiple, such as Figure 4 The structure shown has 3 butterfly rubbers 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com