Balanced switching control circuit for battery management system

A battery management system and control circuit technology, applied in the direction of battery circuit devices, circuit devices, collectors, etc., can solve the problems of high switch cost, cost increase, high cost of switching switches, etc., to facilitate popularization and application, and reduce withstand voltage requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

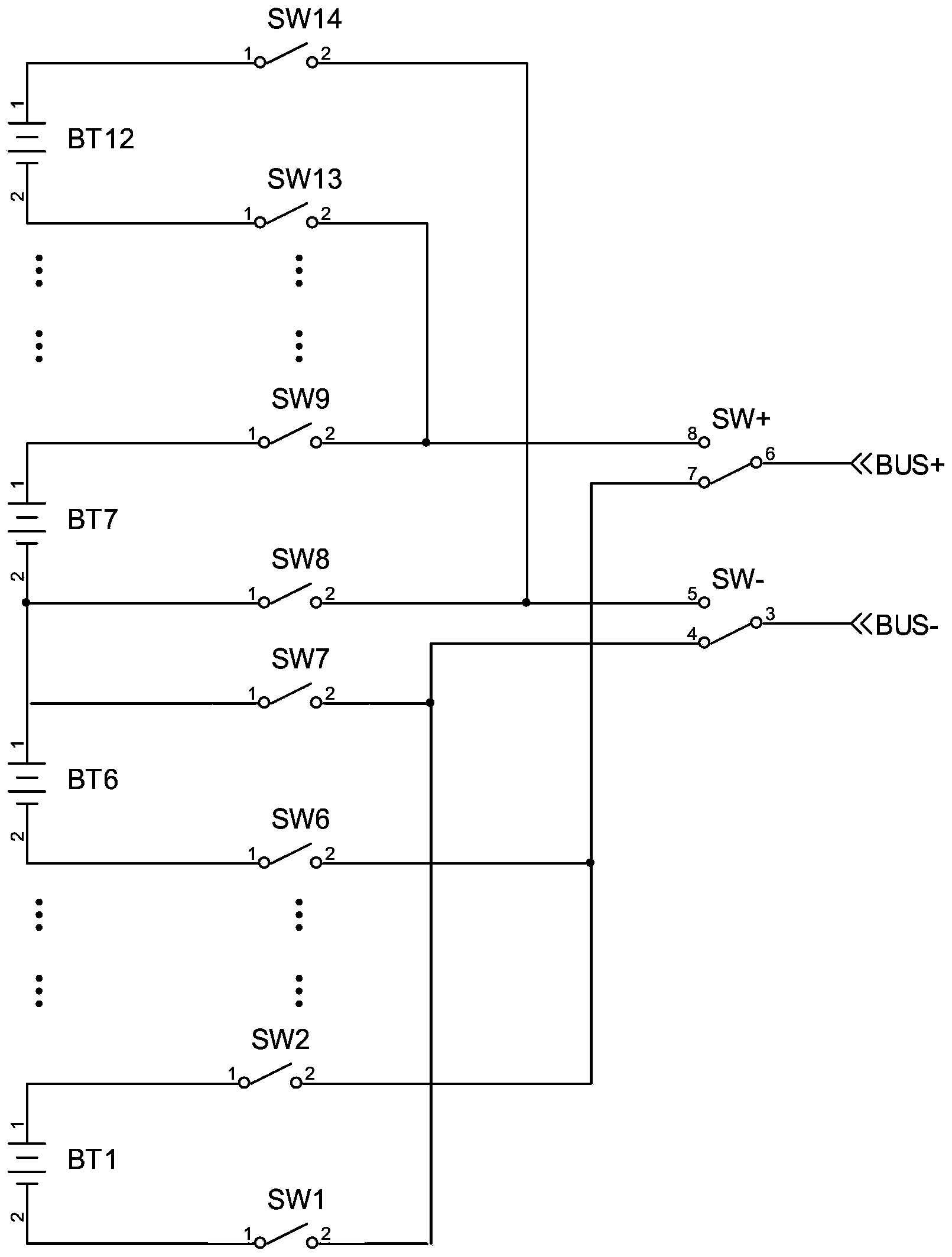

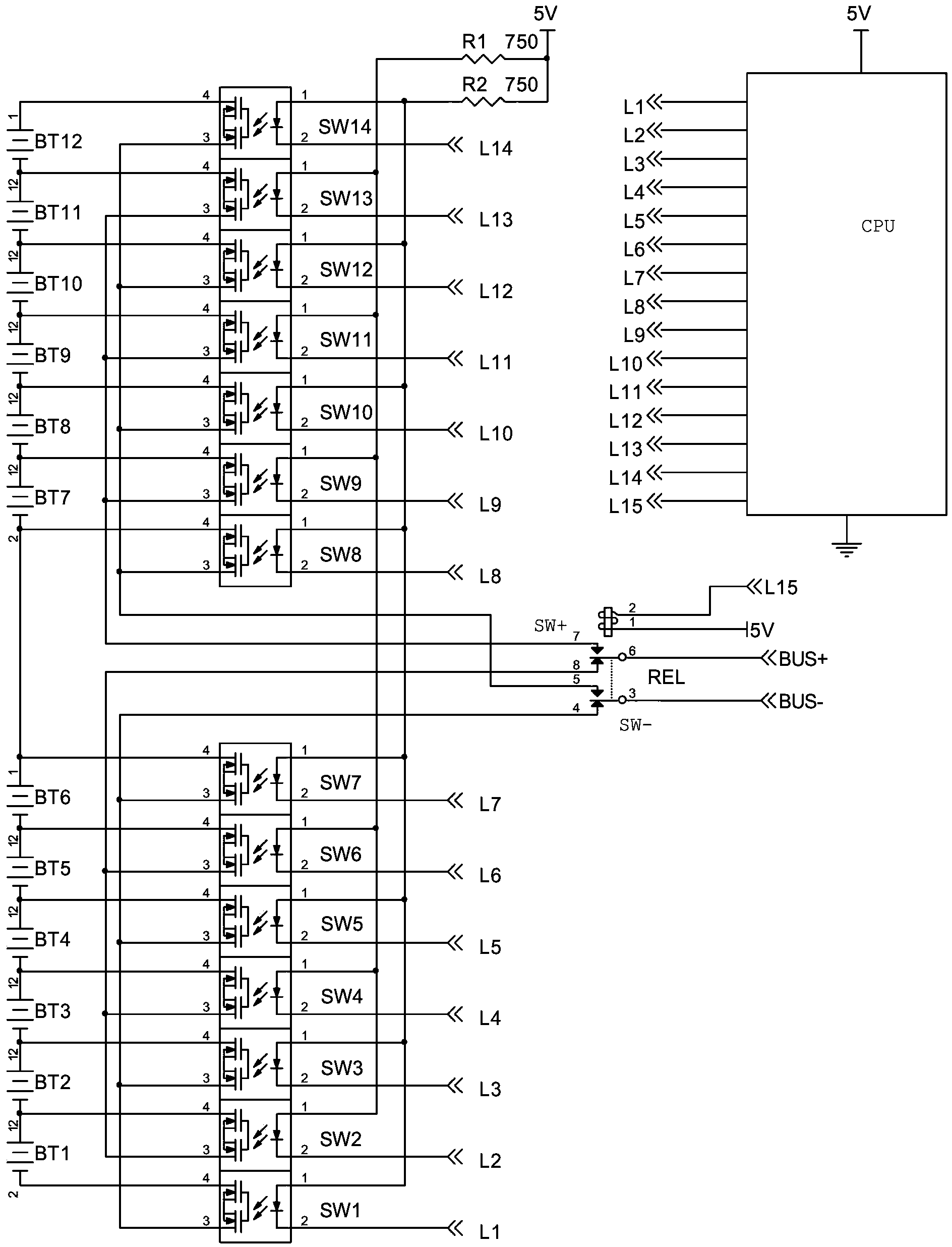

[0032] a kind of like figure 1 , 2In the balanced switching control circuit used in the battery management system shown, the battery cells used to form a series battery pack are lithium iron phosphate batteries BT1 to BT12 with a number of 12 cells, a capacity of 1000AH, and a rated voltage of 3.5V, where The battery cells BT1~BT6 form the lower half series battery group from bottom to top in series order, and the battery cells BT7~BT12 form the upper half series battery group from bottom to top in series order, the first battery of the lower half series battery group The negative pole of the single cell BT1 is the negative pole of the lower half of the series battery group, which is also the negative pole of the series battery group. The positive pole of the last battery cell BT12 of the upper half of the series battery group is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com