Plasma arc starting circuit

A plasma and circuit technology, applied in the direction of plasma, electrical components, and conversion equipment without intermediate conversion to AC, can solve the problems of complex switching circuit structure and high withstand voltage of devices, so as to achieve simple and reliable modules and reduce overall weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

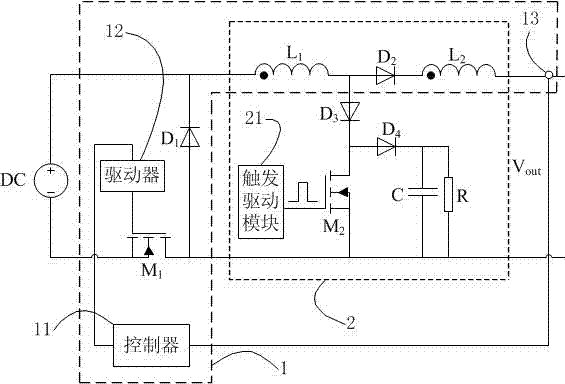

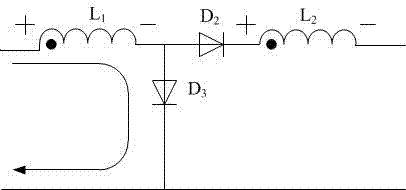

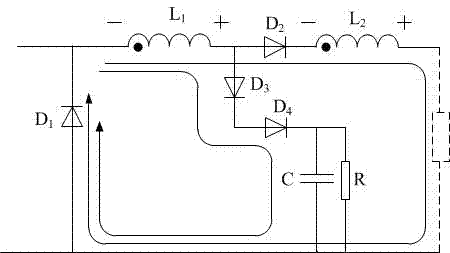

[0030] Such as figure 1 As shown, the plasma arc starting circuit of the embodiment of the present invention includes a step-down type steady current source circuit 1 and a high voltage pulse power supply circuit 2, and the step-down type steady current source circuit 1 includes a controller 11, a driver 12, and a current sampling circuit 13 , coupled inductor L with a center tap 1 and inductance L 2 , and a diode D connected between the positive and negative poles of the DC voltage source DC 1 and the first switching device, the diode D 1 The negative pole of the diode is connected to the positive pole of the DC voltage source DC, and the diode D 1 The positive pole of the first switching device is connected to one end of the first switching device, the other end of the first switching device is connected to the negative pole of the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com