Preparation method of assembly type precast concrete member

A prefabricated concrete and prefabricated technology, which is applied in the preparation of prefabricated prefabricated concrete components and the prefabrication of prefabricated concrete culvert segments, can solve the problems of poor contact between the connecting surface and easy cracking of the concrete at the contact surface, and achieve high manufacturing efficiency , easy pouring quality, convenient assembly and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

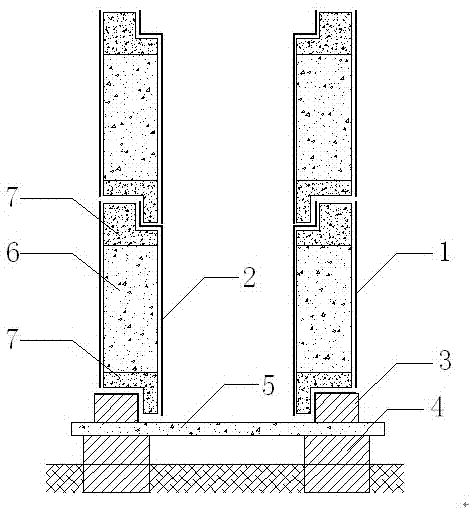

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] The invention intends to prefabricate concrete pipes and culverts by vibrating pipe maker method, and adopts the method of vertical layered pouring of culvert sections to improve the problems of undense connection surfaces of sections and reduce cracking of concrete at contact surfaces. Firstly, the construction preparation work of steel formwork, steel backing ring, steel backing ring and concrete cap is completed in the processing plant, and then prefabricated in the factory according to the following steps.

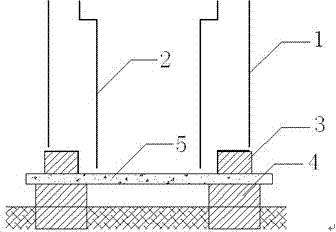

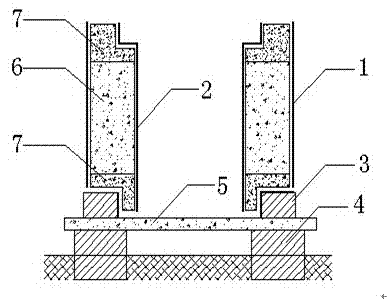

[0020] to combine Figure 1 to Figure 3 , step 1: bury half of the steel spacer 4 in the concrete floor, place the concrete square cap 5 flatly on top of it, align the center of the steel spacer 3 with the center of the steel spacer 4, place the center of the steel spacer 3 Apply release agent on top; place the steel inner mold 2 coated with r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com