304 metastable-state austenitic stainless steel and preparation process thereof

A technology for austenitic stainless steel and its preparation process, which is applied in the field of 304 metastable austenitic stainless steel and its preparation process. It can solve the problems of reduced tensile properties of 304 stainless steel, affecting the processing and forming properties of stainless steel, and reducing plasticity and toughness. Achieve the effect of eliminating defects, improving plasticity and reducing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

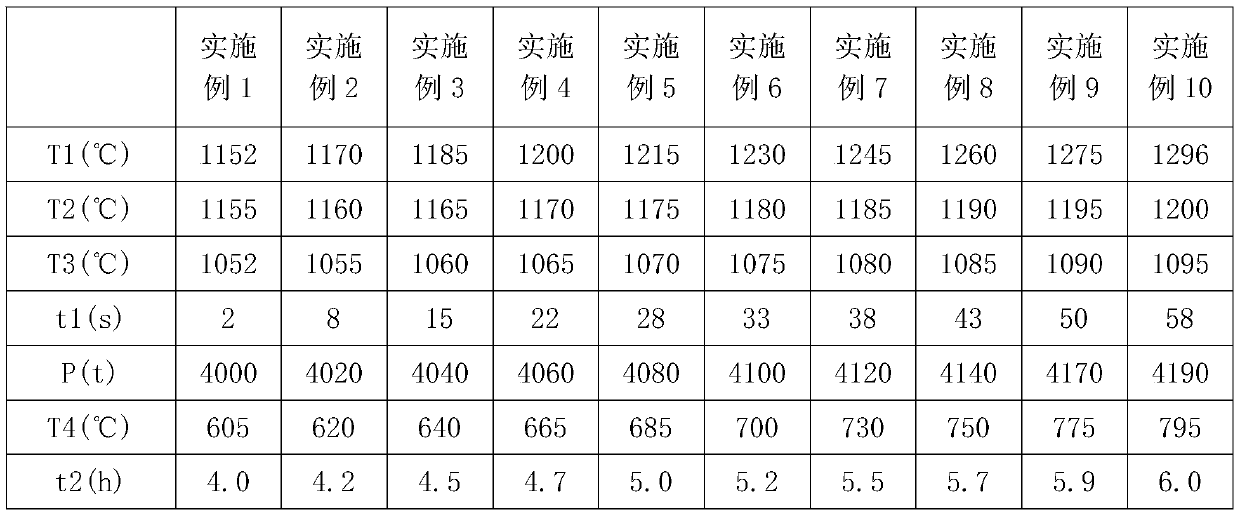

[0031] The preparation process of the 304 metastable austenitic stainless steel includes the following steps:

[0032] S1. Molten steel casting: melting and refining the stainless steel raw materials with the above steel components at a melting temperature T1 of 1150-1300°C, and casting them into stainless steel billets;

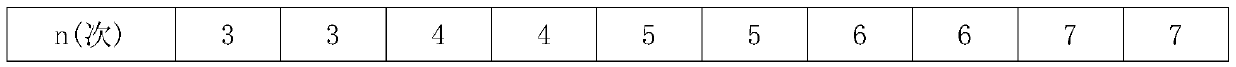

[0033] S2. Hot-rolling annealing treatment: hot-rolling and annealing the stainless steel billet obtained in the step S1, wherein the annealing adopts an isothermal annealing method, the isothermal annealing treatment temperature T4 is 600-800°C, and the annealing time t2 is 4-6h to obtain hot Rolled stainless steel black skin coils, hot-rolled stainless steel black skin coils meet the unit coil weight of 19-20kg / mm, and the yield strength is 600-800N / mm 2 . The hot-rolling start temperature T2 is specified to be above 1150°C, the rolling end temperature T3 is specified to be above 1050°C, and the interval time t1 between each pass is 2-60s for multi-pass r...

Embodiment 1

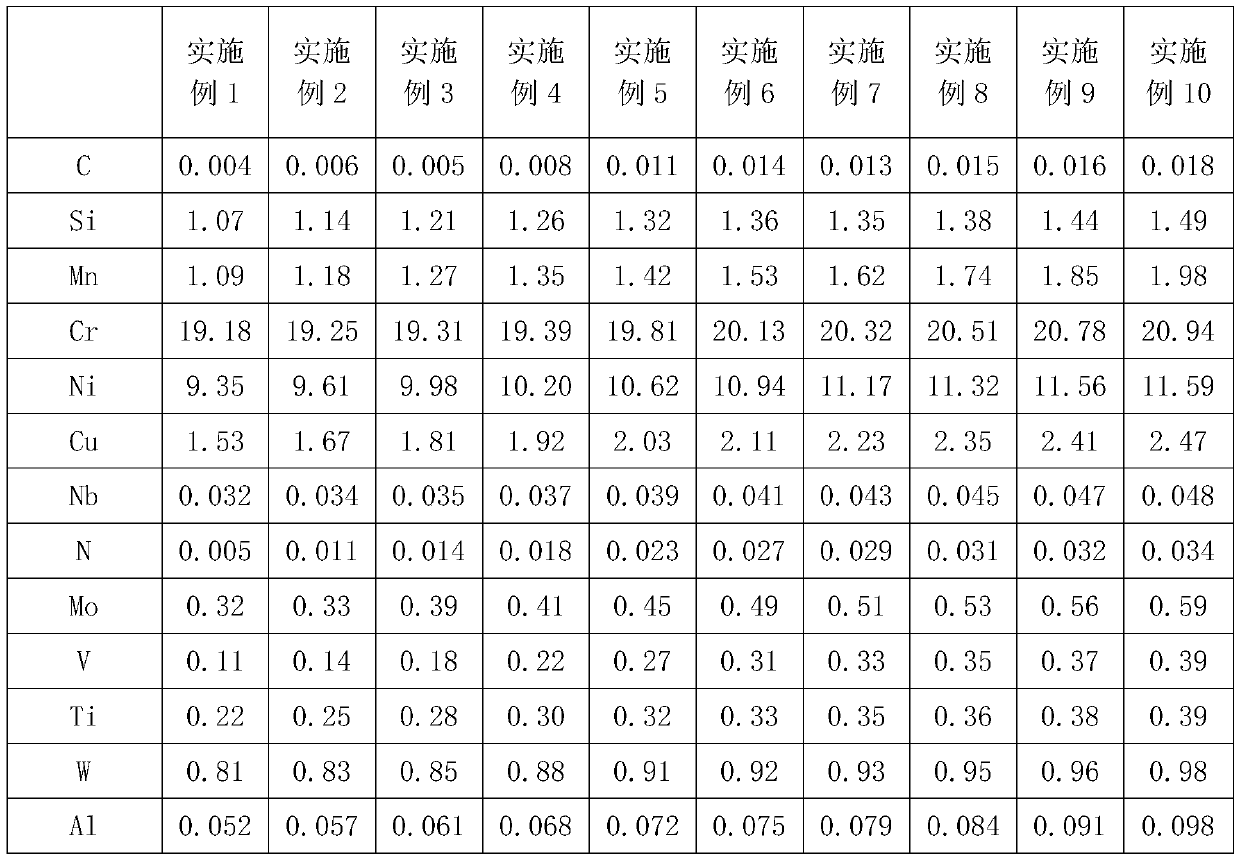

[0036] Example 1: A 304 metastable austenitic stainless steel has the following steel composition, which contains the elements shown in Table 1 in mass %. The preparation process of the 304 metastable austenitic stainless steel is as described above, and the parameters are shown in Table 2.

[0037] Table 1 embodiment 1-10 steel composition table (%)

[0038]

[0039] The preparation process parameter table of table 2 embodiment 1-10

[0040]

[0041]

[0042] The implementation principle and beneficial effects of this embodiment are: adding elements such as Si, Mn, Cu, Nb and N to stainless steel, by suppressing the precipitation of carbides or enriching C in austenite, the stability of austenite and austenite are improved. Reduce the amount of residual body, reduce the content of martensite generated in the process of stretching and stamping, improve the plasticity and toughness of stainless steel during deformation processing, so that 304 stainless steel is not ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com