Processing method of glass fiber floorboards

A glass fiber and processing method technology, applied in the field of floor manufacturing, can solve the problems of weak artificial lamination, short service life, troublesome process, etc., achieve the effects of small shrinkage, saving raw material costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

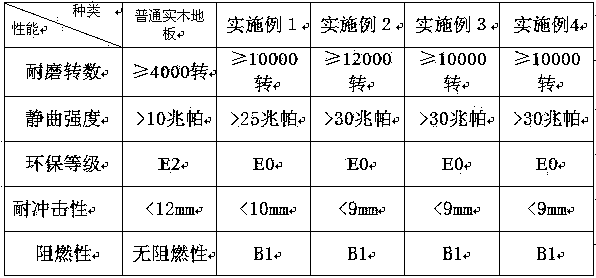

Examples

Embodiment 1

[0050] A processing method for glass fiber flooring, which can produce any standard specification flooring on the existing market, for example: making a finished flooring with a total thickness of 8mm, a decorative board thickness of 3mm, and a distance of 2mm from the edge of the decorative board to the outer edge of the floor, The inner cavity height of steel mold 1 selected is 7mm, and the inner cavity height of steel mold 2 is 8mm. The detailed processing steps are as follows:

[0051] (1) Lay multiple decorative panels on the bottom of the groove mold 1 with a fixing device at the bottom and fix them. The distance between adjacent decorative panels is set to 4 mm, and the decorative panels close to the inner wall of the steel mold 1 are connected to the steel mold 1. The distance of the inner wall ≥ 2 mm;

[0052] (2) Add glass fiber and resin to the groove mold 1, the weight ratio of the two is: 90% glass fiber, 10% resin, and make the two fully mixed, and crystallize t...

Embodiment 2

[0060] The difference from the above-mentioned embodiment is that the total thickness of the finished floor is 16mm, the thickness of the decorative plate is 12mm, and the distance from the edge of the decorative plate to the outer edge of the floor is 3mm. The lumen height is 16mm. When laying the decorative boards in steel mold 1, ensure that the distance between adjacent decorative boards is 6 mm, and the distance between the decorative boards close to the inner wall of steel mold 1 and the inner wall of steel mold 1 is not less than 3 mm. The thickness of the transparent glass fiber cloth added in the second steel mold is 0.3mm, and the total thickness of the added glass fiber, resin and nano-ceramic particles after mixing is 0.3mm. The weight ratio of glass fiber and resin in step (2) is: glass fiber 97%, resin 3%; the weight ratio of glass fiber, resin and nano-ceramic particles added in step (4) is: glass fiber 95%, 4% resin, 1% nano ceramic particles. After the floor...

Embodiment 3

[0063] The difference from the above embodiment is that the finished floor is made with a total thickness of 10mm, a decorative plate thickness of 1mm, and a distance of 1mm from the edge of the decorative plate to the outer edge of the floor. The lumen height is 10mm. When laying the decorative boards in steel mold 1, ensure that the distance between adjacent decorative boards is 2 mm, and the distance between the decorative boards close to the inner wall of steel mold 1 and the inner wall of steel mold 1 is not less than 1 mm. The thickness of the transparent glass fiber cloth added in the second steel mold is 0.3mm, and the total thickness of the added glass fiber, resin and nano-ceramic particles after mixing is 0.4mm. The weight ratio of glass fiber and resin in step (2) is: glass fiber 95%, resin 5%; the weight ratio of glass fiber, resin and nano-ceramic particles added in step (4) is: glass fiber 90%, 8% resin, 2% nano ceramic particles. After the floor substrate sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com