Synthetic method of 2-(trimethylsilyl)-ethoxymethyl chloride

A technology of ethoxymethyl chloride and trimethylsilyl group, applied in the field of 2-ethoxymethyl chloride synthesis, can solve the problems of low cost, cost restriction, high price and the like, and achieves cost reduction, energy saving and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

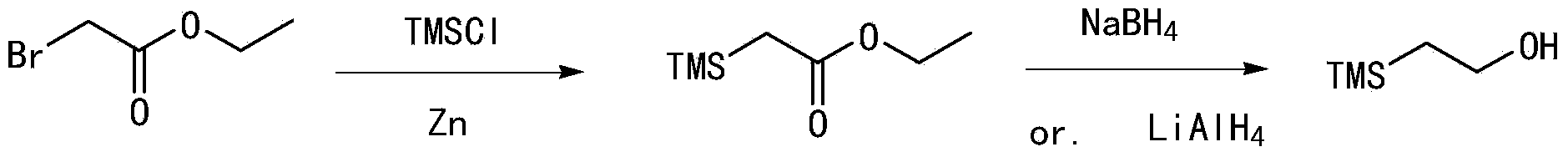

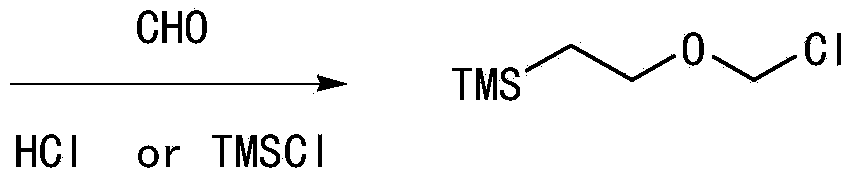

Method used

Image

Examples

Embodiment 2

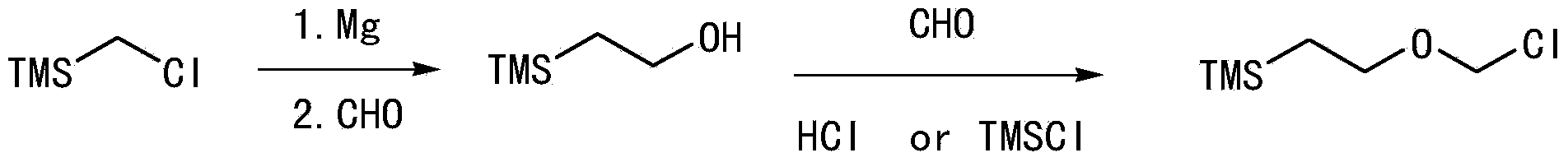

[0030] Example 2 According to the steps in Example 1, the type of the second step trimethylsilyl coupling reaction is adopted format exchange method:

[0031]

[0032] After exchange with the isopropyl format, the target product can also be obtained according to the above method, and the yield is 85%.

Embodiment 3

[0033] Example 3 According to the steps in Example 1, the type of the second step trimethylsilyl coupling reaction adopts the butyllithium method:

[0034]

[0035] Using butyllithium to react at low temperature, the target product can also be obtained according to the above method, and the yield is 55%.

Embodiment 4

[0036] Example 4 According to the steps in Example 1, the type of the second step trimethylsilyl coupling reaction described herein adopts a strong base method:

[0037]

[0038] Reaction with a strong base can also obtain the target product according to the above method, and the yield is 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com