Preparation method of high-purity DOPO (9,10-dihydro-9-oxa-10- phosphaphenanthrene-10-oxide) derivative

A derivative and high-purity technology, applied in the field of flame retardants, can solve problems affecting applications and achieve short reaction routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

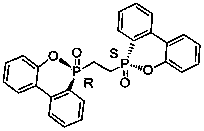

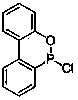

Image

Examples

Embodiment 1

[0017] Embodiment 1, the preparation of DOPO derivative compound I (add catalyst I)

[0018] Add CDOP (47 g, 0.20 mol), triethylamine (20.24 g, 0.20 mol), sodium iodide (1.50 g) and 100 ml xylene to the flask, and slowly add ethylene glycol (4.97 g , 0.08 mol), keep the temperature of the system not exceeding 20 degrees during the dropwise addition, react at about 20 degrees for 2 hours after the addition, and then raise the temperature to 120 degrees for 3 hours. After cooling, filter, add 100mL of ethanol to the filtrate, stir at 80°C for half an hour, then filter while hot to obtain 30.4g of the product, with a yield of 83%. (Because excess CDOP can be recycled, the yield is calculated based on ethylene glycol).

Embodiment 2

[0019] Embodiment 2, preparation of DOPO derivative compound I (without catalyst I)

[0020] Add CDOP (70.4 g, 0.30 mol), iodine (2.0 g) and 80 ml of diphenylmethane into the flask, heat to 160 degrees, then slowly add ethylene glycol (9.31 g, 0.15 mol) to it, after adding The reaction was continued at temperature for 20 hours. Cool to about 80 degrees, add 90mL of ethanol to the system, stir for half an hour, and filter while hot to obtain 55.1g of the product, with a yield of 80%.

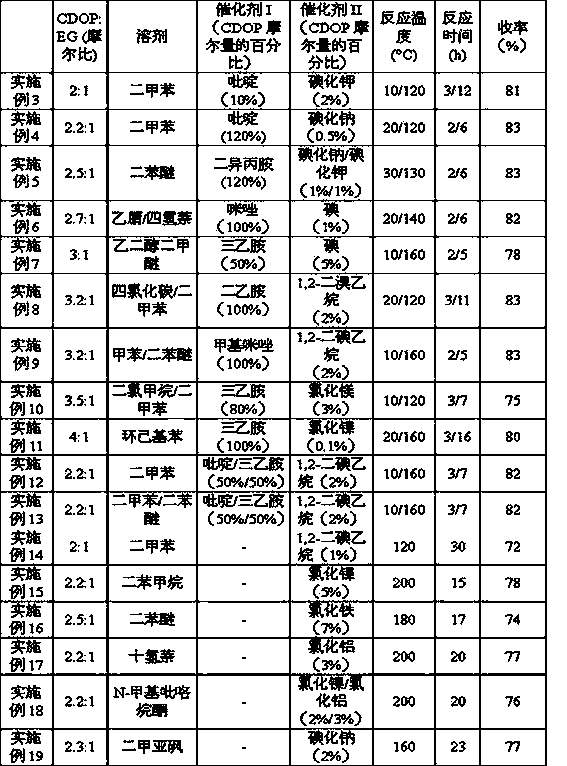

Embodiment 3-19

[0021] Embodiment 3-19, with reference to Embodiment 1 and 2, modify some parameters, as shown in the following table:

[0022]

[0023] In this table, as in Example 3, the reaction temperature is 10 / 120, and the reaction time is 3 / 12, which means that the temperature of the system should not exceed 10 degrees during the dropwise addition of ethylene glycol, and react at about 10 degrees for 3 hours after the addition , and then warming up to 120 degrees for 12 hours, the other embodiments are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com