Process unit and method for removing heavy hydrocarbon during liquefaction process of natural gas

A technology for process equipment and natural gas, applied in liquefaction, refrigeration and liquefaction, petroleum industry and other directions, can solve the problems of pressure energy waste, high requirements for pressure regulating equipment and pipeline equipment, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

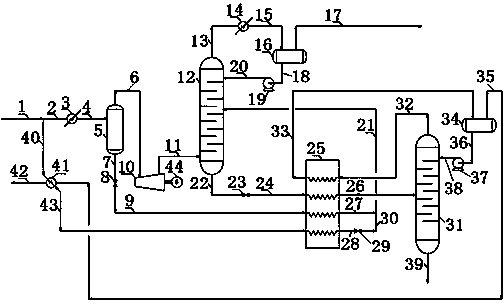

[0017] A process device for removing heavy hydrocarbons during natural gas liquefaction, such as figure 1 shown.

[0018] In the figure: 1, pipeline; 2, pipeline; 3, precooler; 4, pipeline; 5, hydrocarbon-liquid separator; 6, pipeline; 7, pipeline; 8, first throttle valve; 9, pipeline; 10, Expander; 11. Pipeline; 12. Heavy hydrocarbon removal tower; 13. Pipeline; 14. Heavy hydrocarbon removal tower condenser; 15. Pipeline; 16. Heavy hydrocarbon removal tower reflux tank; 17. Pipeline; 18. Pipeline; 19. Heavy hydrocarbon removal tower reflux pump; 20, pipeline; 21, pipeline; 22, pipeline; 23, second throttle valve; 24, pipeline; 25, hydrocarbon removal cold box 26, pipeline; 27, pipeline; 28, pipeline; 29 , third throttle valve; 30, pipeline; 31, deethanizer; 32, pipeline; 33, pipeline; 34, deethanizer reflux tank; 35, pipeline; 36, pipeline; 37, deethanizer reflux Pump; 38, pipeline; 39, pipeline; 40, pipeline; 41, ethane gas heat exchanger; 42, pipeline; 43, pipeline; 44, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com