Slant grouting control steel anchor pipe frame and construction method thereof

A technology of steel anchor pipe and grouting pipe, applied in excavation, foundation structure engineering, sheet pile wall, etc., can solve the problem of limited anti-sliding ability, and achieve the effect of increasing anti-sliding force, fast construction and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

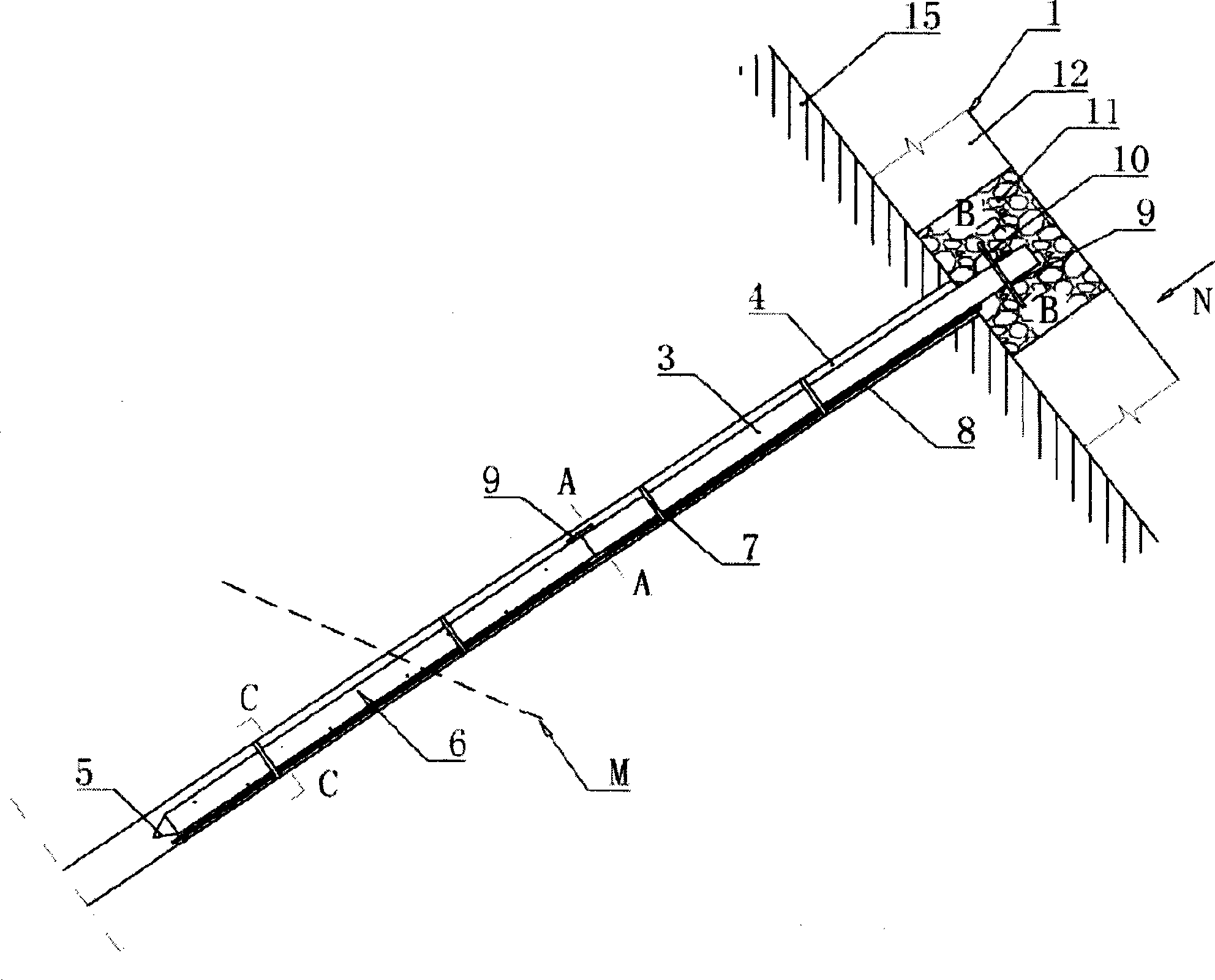

[0030] see Figure 1 to Figure 5 , the oblique control grouting steel anchor pipe frame of the present invention is composed of seven parts such as a frame beam 1, a steel anchor pipe 3, an anchor pipe hole 4, a primary grouting pipe 8, a centering ring 7, a grouting body, and a steel backing plate 10. .

[0031] 1) Frame Beam 1

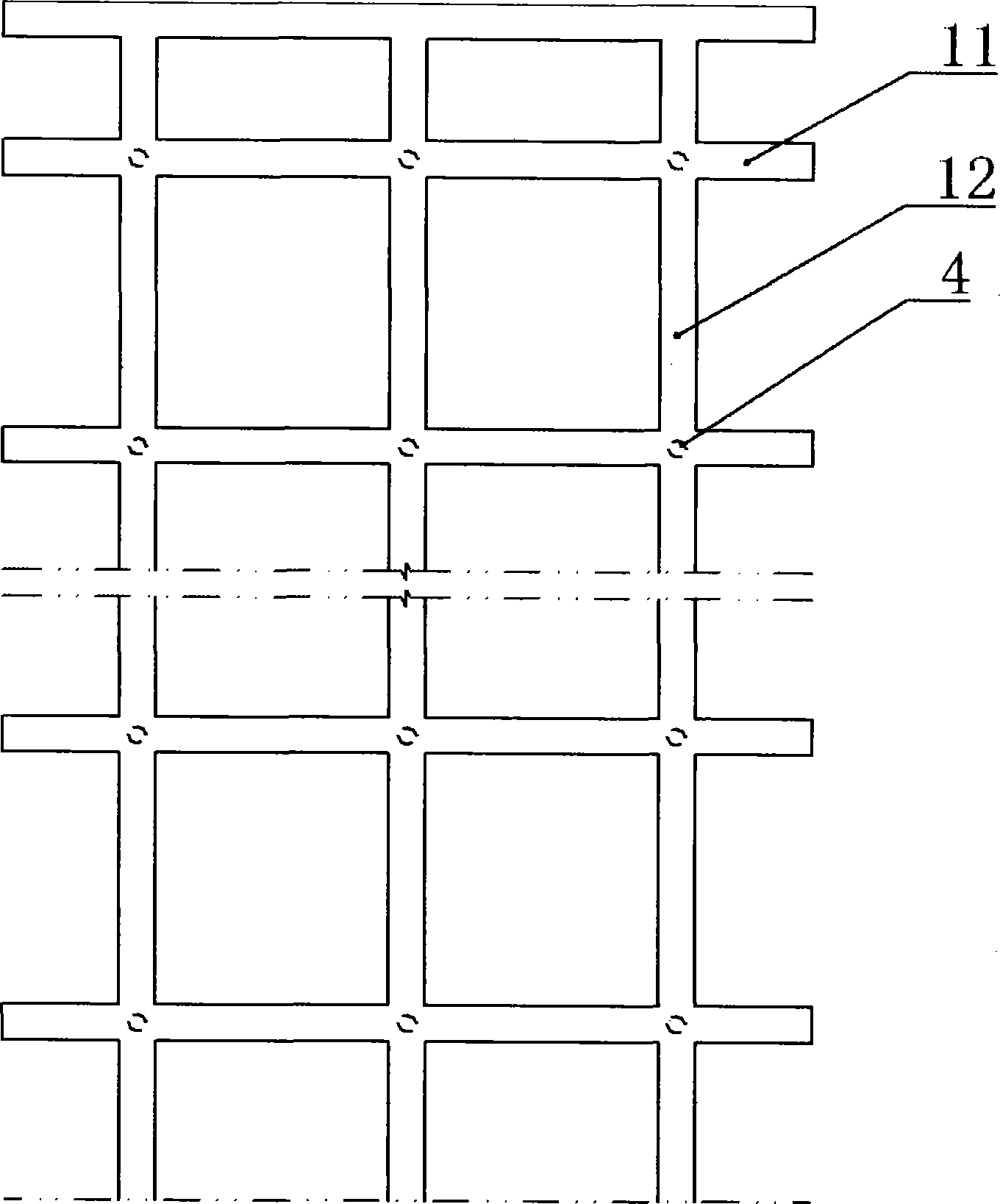

[0032] The frame beam 1 is composed of reinforced concrete beams 11 and vertical ribs 12 (grid shape), fixed on the surface of the slope 15, and mainly plays the role of surface slope consolidation and transmission of landslide thrust to deep anchors.

[0033] 2) Steel anchor pipe 3

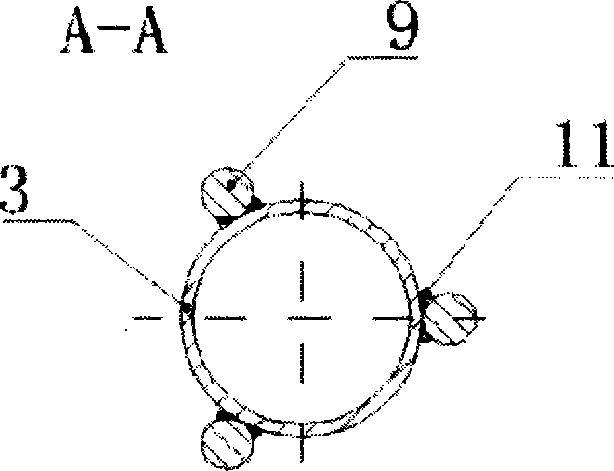

[0034] The steel anchor pipe 3 is the main force-bearing member, relying on its own tensile strength to resist landslide thrust. Generally, 6m long, Φ51×5mm seamless steel pipe is used, which can be lengthened or shortened according to the needs of the project. Set the secondary grouting hole 6 in the steel anchor pipe 3 of the control grouting part, and the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com