Spraying type tail gas processing device for coal mine anti-explosion vehicle

An explosion-proof vehicle and exhaust gas treatment technology, applied in exhaust devices, mufflers, engine components, etc., can solve problems such as engine power loss and large exhaust back pressure, and achieve the effect of eliminating sparks, reducing smoke and dust, and fully treating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

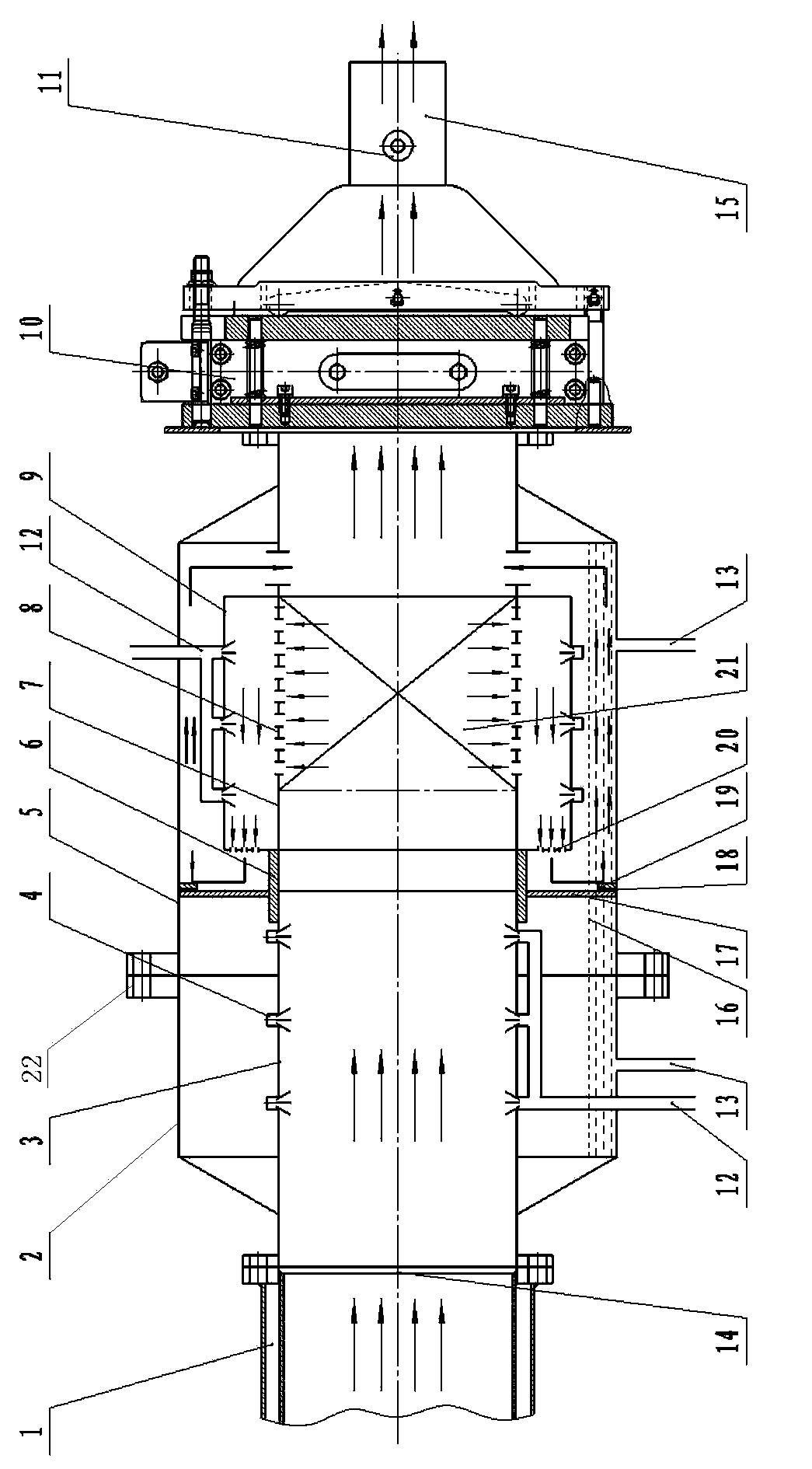

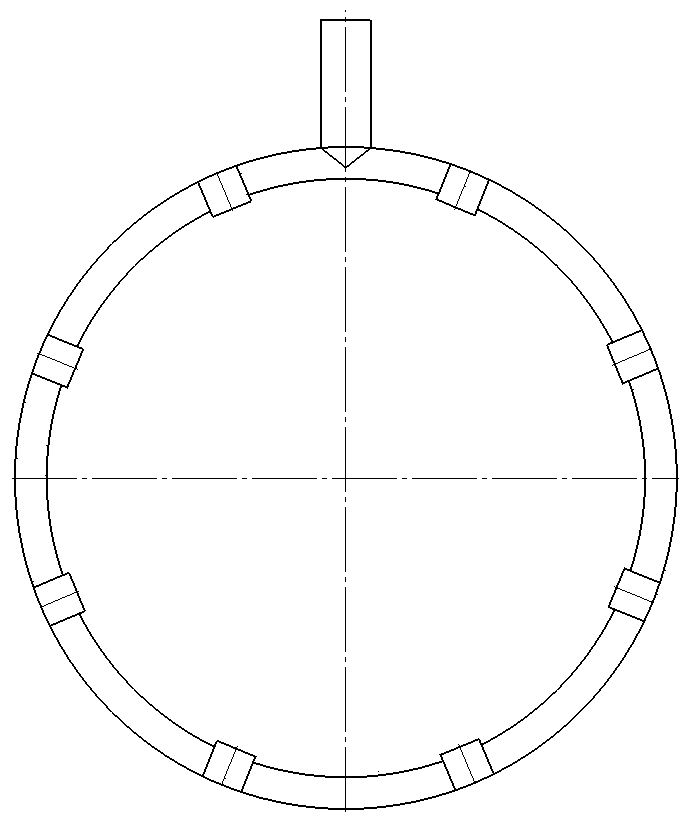

[0018] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0019] The spray type exhaust gas treatment device used for explosion-proof vehicles in coal mines is a detachable structure in the shape of a "pen cap", which is convenient for installation and disassembly when adjusting the number and type of nozzles and the need for maintenance of water supply pipelines, such as figure 1 As shown, it includes a cylinder, one end of the cylinder is the exhaust gas inlet, and the other end is the exhaust gas outlet. The cylinder includes an outer cannula and an inner cannula. The outer cannula includes the outer cannula I2 and the The outer cannula II5 and the inner cannula include the inner cannula I3 and the inner cannula II7 arranged sequentially from the exhaust gas inlet and connected to each other. The free end of the inner cannula I3 is connected to the exhaust gas inlet 14, and the free end of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com