Petroleum pipeline cutting mark belt

A technology for oil pipelines and marking tapes, applied in the directions of marking, pipe components, pipes/pipe joints/fittings, etc., can solve the problems of wasting manpower, the drawn lines cannot be guaranteed to be flush, affecting the connection and sealing effect of new pipe sections, etc. To achieve the effect of ensuring flatness and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

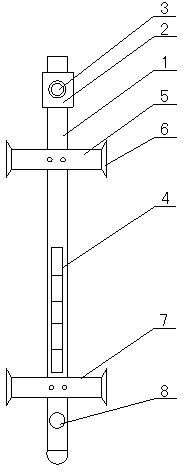

[0015] like figure 1 As shown, the oil pipeline cutting marking tape according to the embodiment of the present invention includes a steel strip sheet 1, a rectangular connector 2 is installed at one end of the steel strip sheet 1, and an outwardly protruding The steel column 3 is located at the other end of the steel strip 1 opposite to the rectangular connector 2 to open a positioning screw hole 8 and the diameter of the positioning screw 8 is the same as the diameter of the bottom surface of the steel column 3; the surface of the steel strip 1 is set A multi-level positioning hole 4 composed of a number of rectangular sockets, the steel column 3 is inserted into one of the multi-level positioning holes 4 or the only circular positioning screw hole 8 for internal fixation; A first horizontal fixing frame 5 and a second horizontal fixing frame 7 are respectively arranged at the two end positions, and steel claws 6 are respectively arranged at both ends of each horizontal fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com