Powder average particle size determination method

A technology of average particle size and measurement method, which is applied in the direction of measuring device, particle size analysis, particle and sedimentation analysis, etc., can solve the problem that consumers have no way to directly distinguish, and achieve the effect of fast test speed, high accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

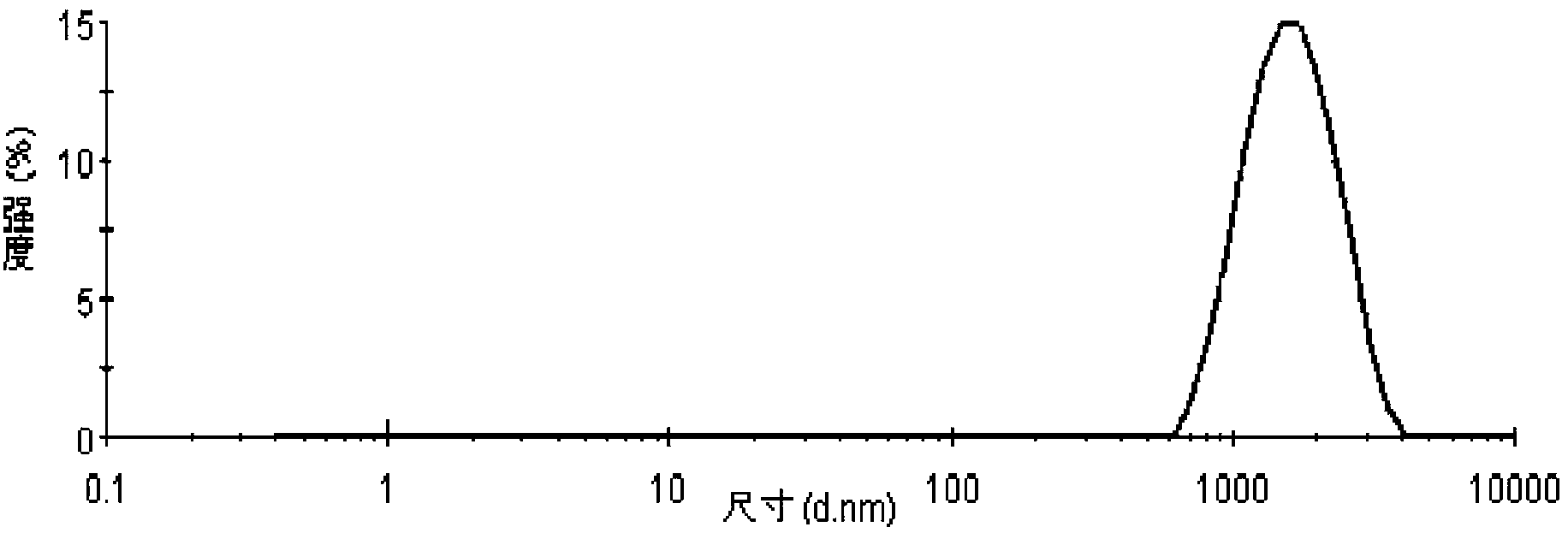

[0033] Embodiment 1: the mensuration of pearl powder Z-1 average particle diameter

[0034] Weigh 0.025g pearl powder Z-1 sample and place it in a 50mL beaker; prepare a 20g / L sodium hexametaphosphate solution; add 2 drops of the prepared sodium hexametaphosphate solution to the beaker, and stir with a glass rod to moisten Wet dispersion; add 20mL deionized water to the beaker, place the solution on an ultrasonic disperser for ultrasonic dispersion for 10 minutes, and obtain a white suspension; take 2mL of the white suspension and drop it into a quartz cuvette, and put it into a laser particle size analyzer In this method, the dispersion liquid is deionized water, the temperature is 25°C, and it is allowed to stand for 5 minutes before scanning, the detection angle of scanning is 90°, the number of measurements is 2 times, and the number of scanning times for each measurement is 20 times. Under the condition of 10s, measure the particle size distribution diagram of pearl powde...

Embodiment 2

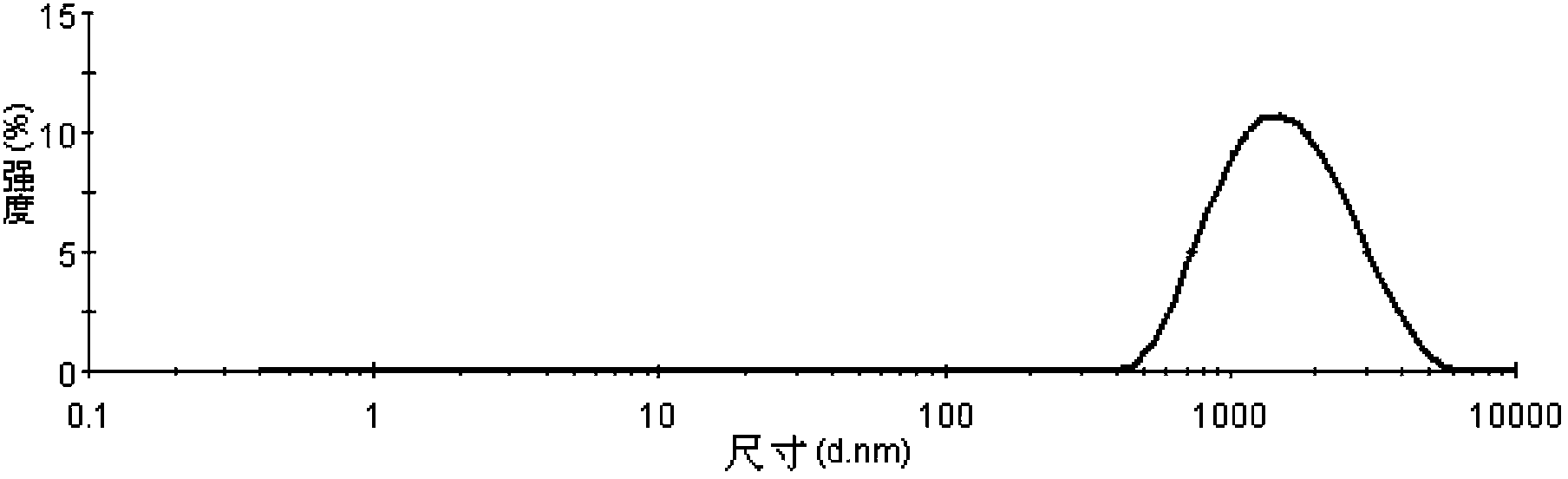

[0036] Embodiment 2: the mensuration of pearl powder Z-2 average particle diameter

[0037] Weigh 0.02g pearl powder Z-2 sample and place it in a 50mL beaker; prepare 20g / L sodium hexametaphosphate solution; add 2 drops of the prepared sodium hexametaphosphate solution to the beaker, and stir with a glass rod to moisten Wet dispersion; add 15mL deionized water to the beaker, place the solution on an ultrasonic disperser for ultrasonic dispersion for 20 minutes, and obtain a white suspension; take 2mL of the white suspension and drop it into a quartz cuvette, and put it into a laser particle size analyzer In the above conditions, the dispersion liquid is deionized water, the temperature is 25°C, the condition is to stand still for 5 minutes before scanning, the detection angle is 90°, the number of measurements is 4 times, the number of times of each scan is 15 times, and the running time of each time is 10s. Next, measure the particle size distribution of pearl powder.

[003...

Embodiment 3

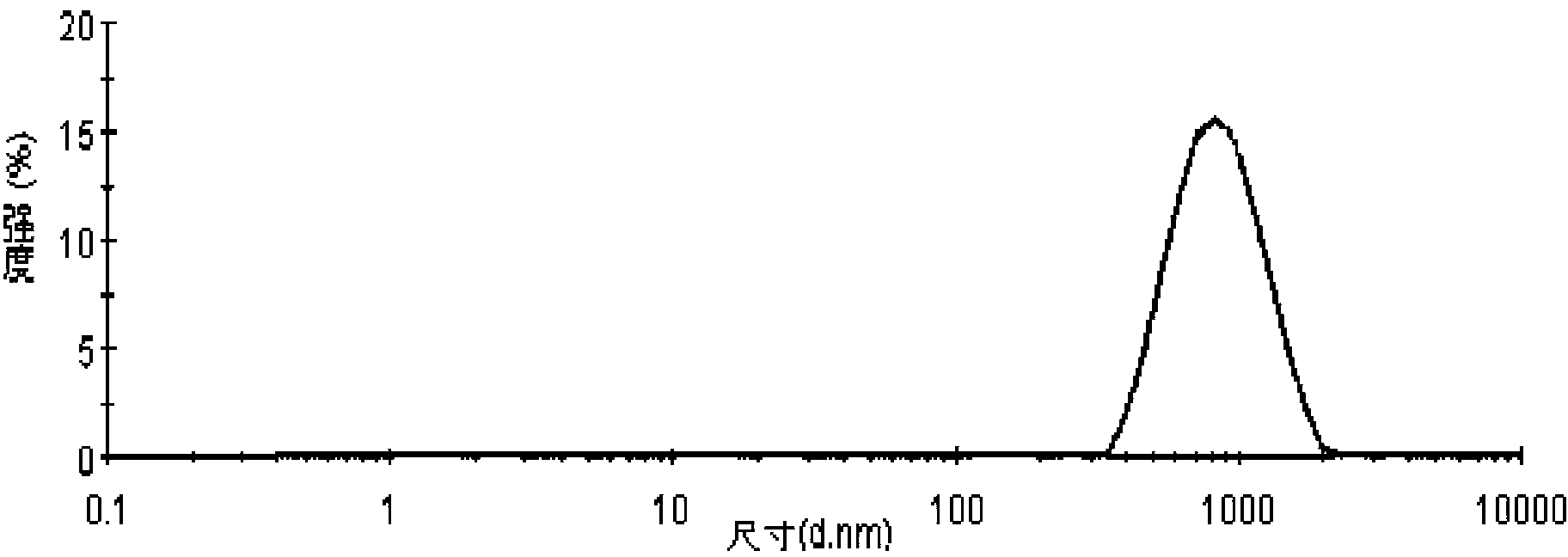

[0039] Embodiment 3: the mensuration of pearl powder Z-3 average particle diameter

[0040] Weigh 0.05g pearl powder Z-3 sample and place it in a 50mL beaker; prepare a 20g / L sodium hexametaphosphate solution; add 2 drops of the prepared sodium hexametaphosphate solution to the beaker, and stir with a glass rod to moisten Wet dispersion; add 20mL deionized water to the beaker, place the solution on an ultrasonic disperser for ultrasonic dispersion for 20 minutes, and obtain a white suspension; take 2mL of the white suspension and drop it into a quartz cuvette, and put it into a laser particle size analyzer In the above conditions, the dispersion liquid is deionized water, the temperature is 25°C, the condition is to stand still for 5 minutes before scanning, the detection angle is 90°, the number of measurements is 3 times, the number of times of each scan is 25 times, and the running time of each time is 10s. Next, measure the particle size distribution of pearl powder.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com