Linear motion conversion method for servo motor

A technology of linear motion and servo motors, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of low thrust density of motors and high processing costs of motors, and achieve improved protection levels and service life, improved protection levels, and good sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

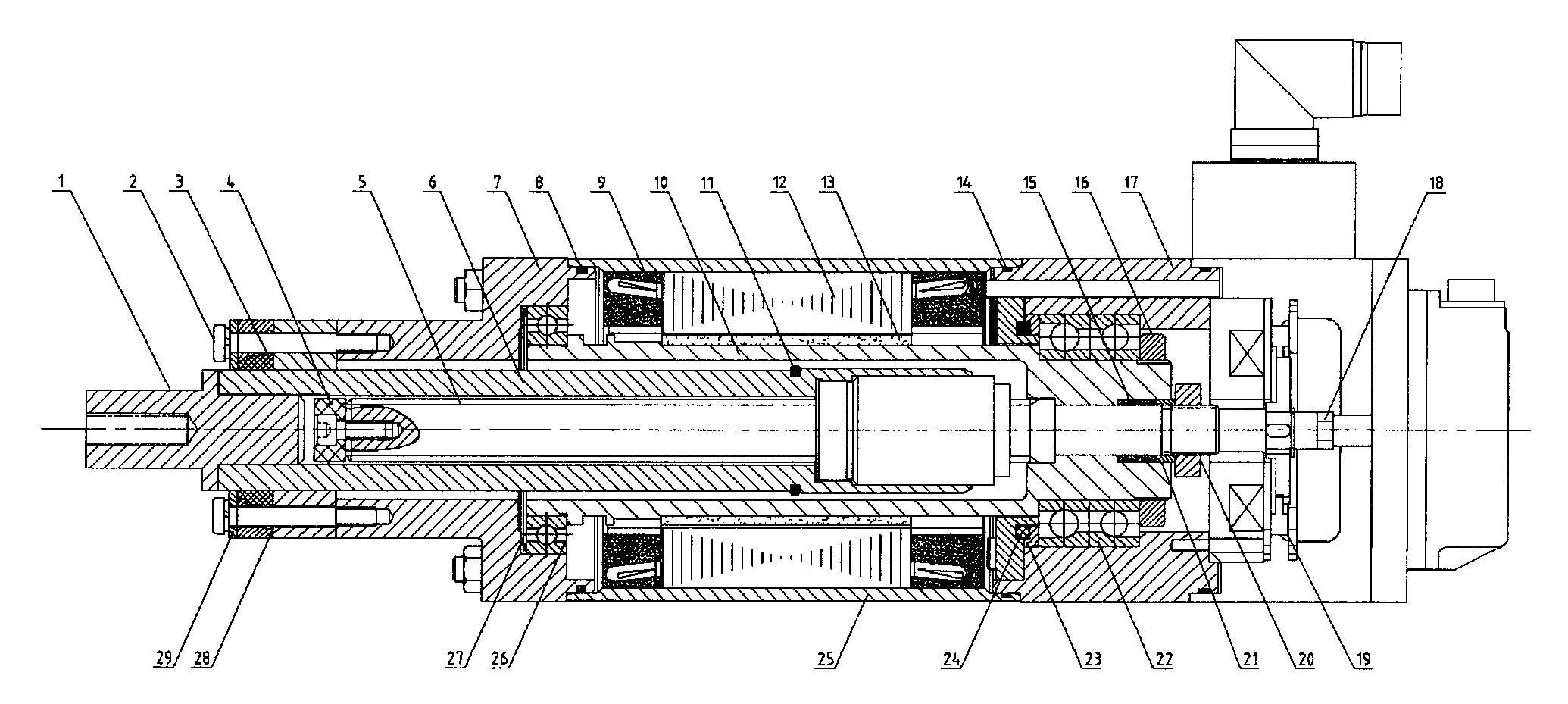

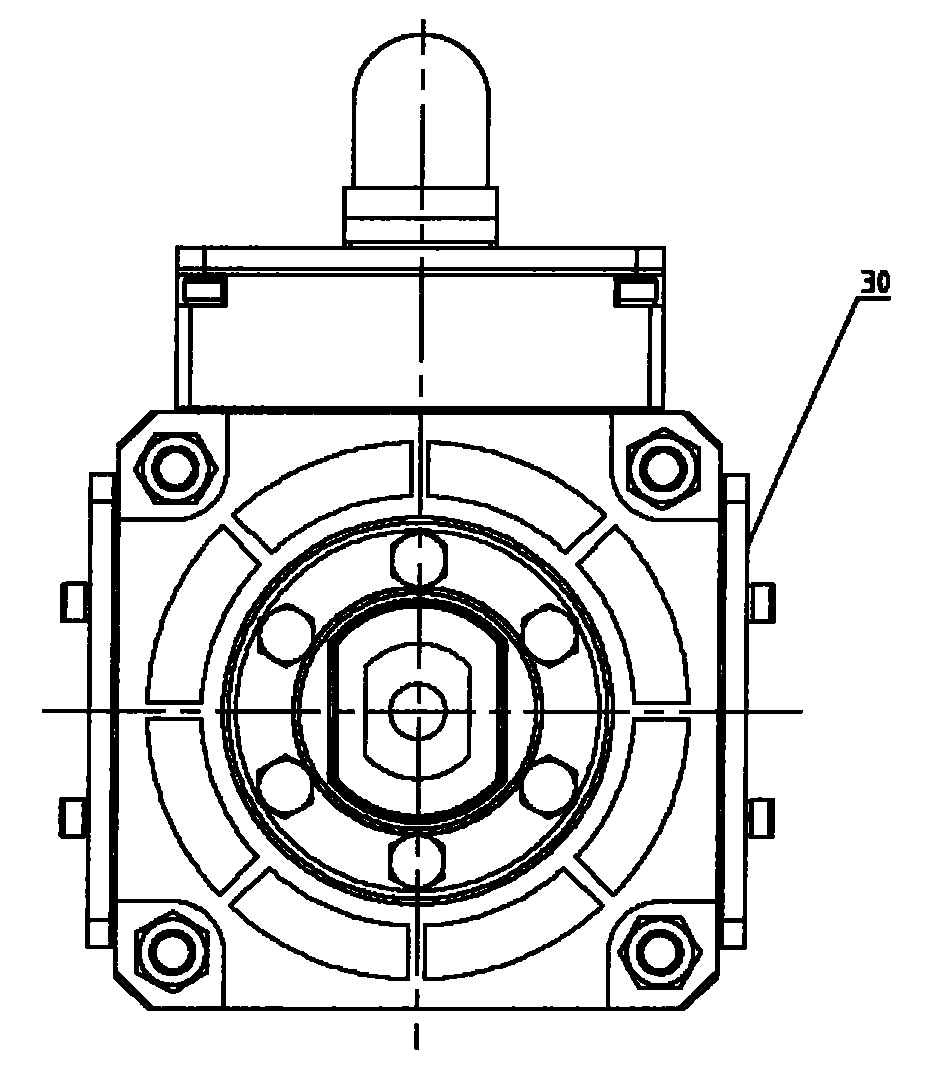

[0015] Such as figure 1 , figure 2 As shown, a new type of linear motion conversion method for servo motors is specifically implemented as follows: the motor shaft 1 is placed on the left side of the motor, and can be connected with an external load through a coupling, and the shaft 1 is embedded in the sleeve 6 through an interference connection , the ball screw 5 and the shaft sleeve 6 are connected through threads, and fastened with thread glue, the shaft sleeve 6 and the rotor 10 are connected through the expansion sleeve 15, and the compression block 21 locks the expansion sleeve 15 through the lock nut 20 fixed, the magnetic steel 13 is evenly attached to the rotor 10, the front end cover 7 and the rotor 10 are connected by the front bearing 26, the wave spring washer 27 is placed on the left side of the front bearing 26, and the rear end cover 17 and the rotor 10 are connected by the angular contact bearing 22. Connection, the left side of the angular contact bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com