Generating and electrowelding dual-purpose machine

A generator and dual-purpose technology, applied in the direction of arc welding equipment, electromechanical devices, electrical components, etc., can solve the problems that are not suitable for energy saving requirements, limited power supply functions, limited use of space, etc., to achieve stable power supply at the power generation end, high performance Stable, high-quality power effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

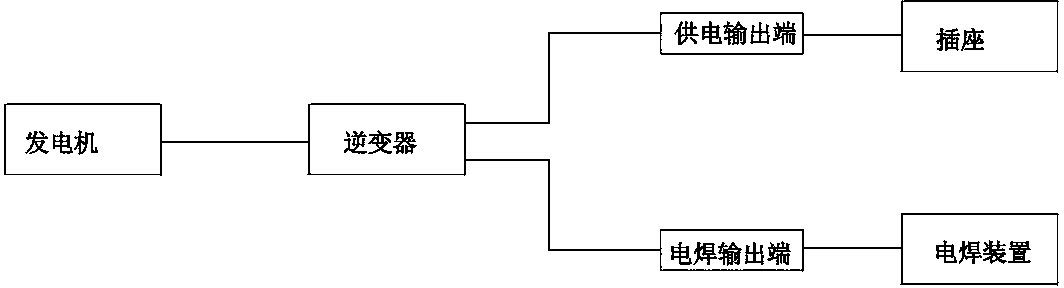

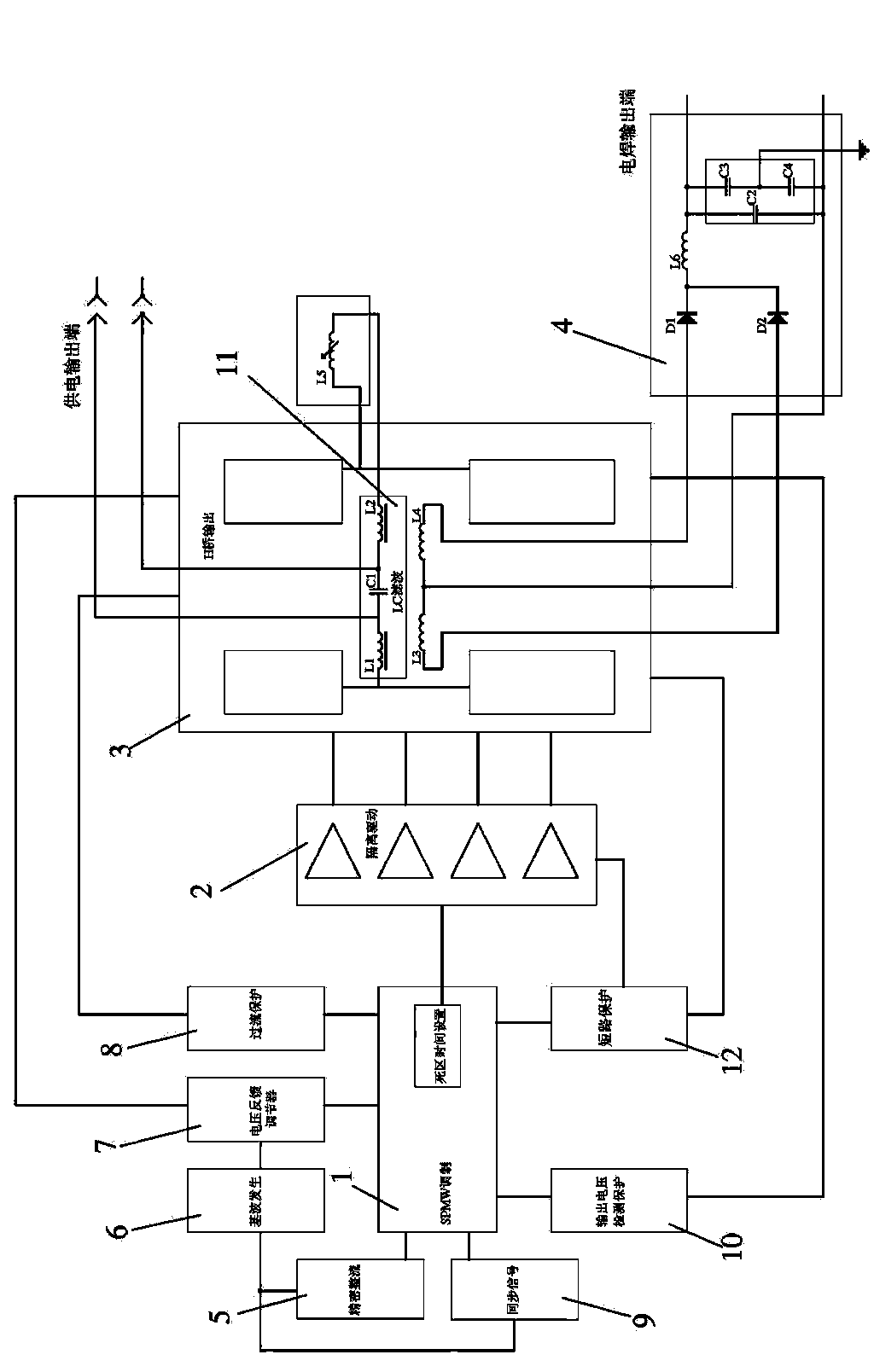

[0017] Such as figure 1 and figure 2 As shown, a dual-purpose machine for power generation and electric welding includes a generator, an inverter, a power supply output terminal, an electric welding output terminal, an electric welding device and a socket. The generator is connected to the inverter, and the inverter is connected to a power supply output terminal and welding output terminal, the power supply output terminal is connected to a socket, and the electric welding output terminal is connected to an electric welding device, wherein the internal circuit of the inverter, electric welding output terminal and power supply output terminal is mainly composed of SPMW modulation module 1, isolation drive module 2 and H bridge output module 3, which are connected in turn, wherein the LC filter module 11 in the H-bridge output module is provided with main filter inductors L1 and L2, the power supply output terminal is connected to the middle of the main filter inductors L1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com