Casting and forging method of metal piece, and casting and forging apparatus

A forming method and technology of forming equipment, applied in metal processing equipment, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. Effect of grain oxidation, shortening process time, and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A metal casting and forging method and casting and forging equipment according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

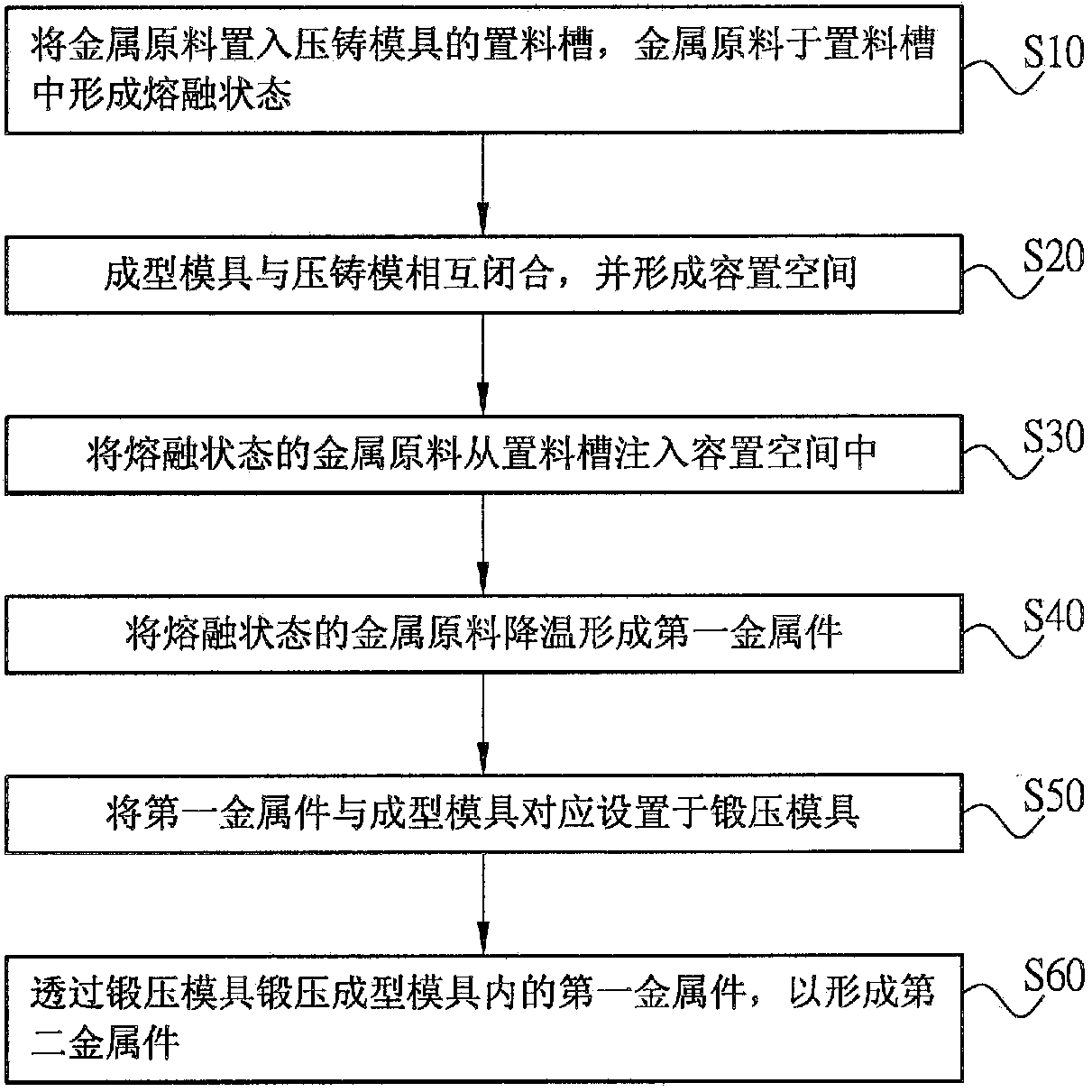

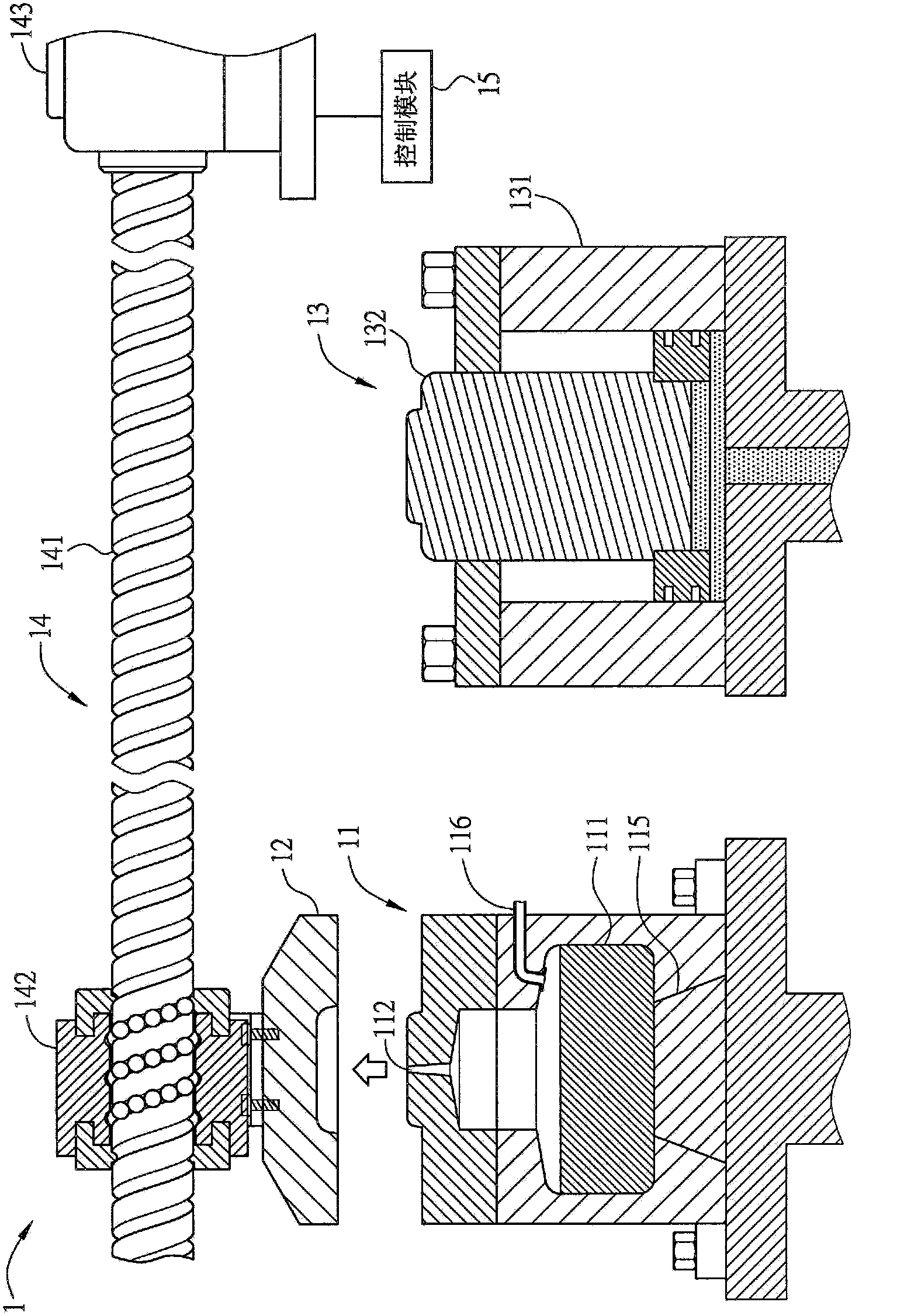

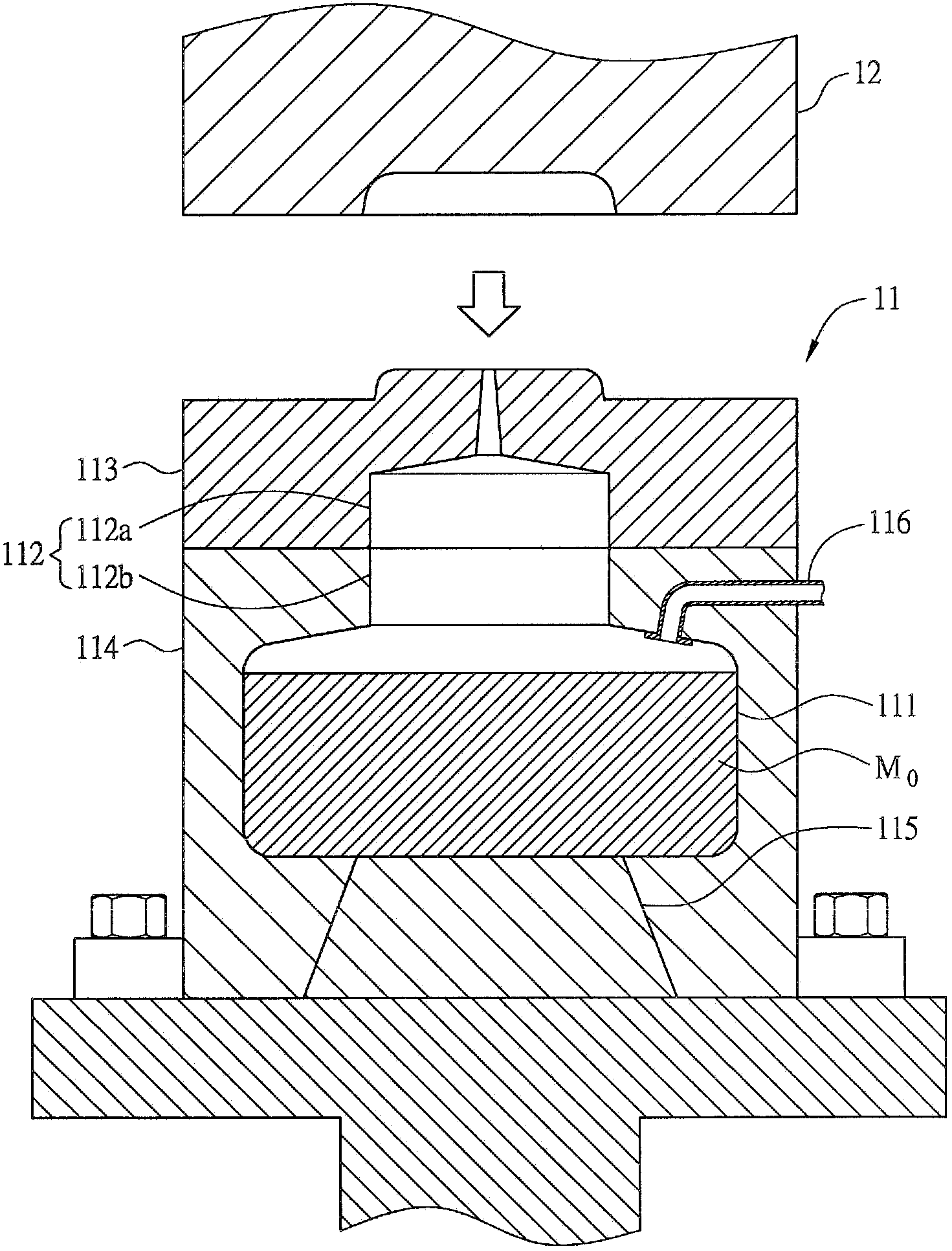

[0019] figure 1 For a flow chart of the steps of a method for casting and forging metal parts according to an embodiment of the present invention, please refer to figure 1 shown. A method for casting and forging metal parts in this embodiment may include the following steps: placing metal raw materials into a trough of a die-casting mold, and the metal raw materials form a molten state in the trough (S10); forming the mold and the die-casting mold closing each other to form an accommodating space (S20); injecting the molten metal raw material from the trough into the accommodating space (S30); cooling the molten metal raw material to form a first metal piece (S40); The metal part and the forming die are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com