Pipeline welding robot for field construction welding of special steel

A welding robot, special steel technology, applied in welding equipment, manufacturing tools, characteristics of welding rods, etc., can solve the problems of unstable welding quality, more welding smoke, strong heat radiation, etc., to shorten welding time, high welding quality, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

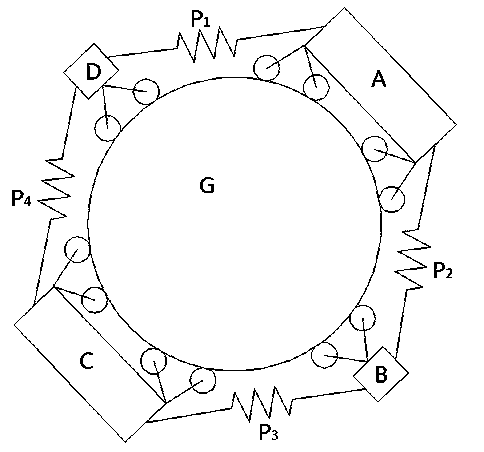

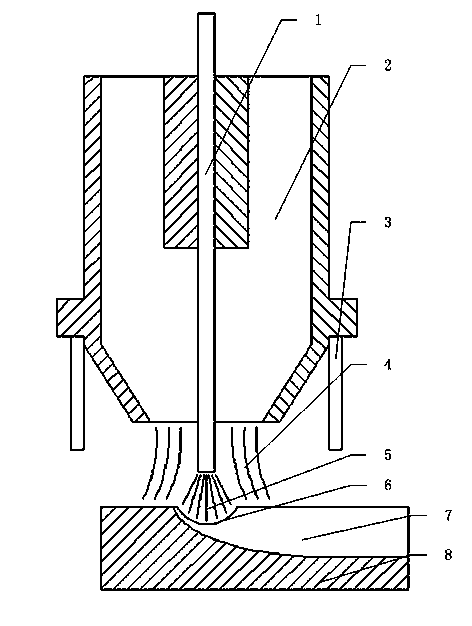

[0039] Such as figure 1 As shown, a pipe welding robot for field construction welding of special steel, including

[0040]Welding vehicle, the execution unit to complete the welding task;

[0041] Auxiliary vehicle to complete the pre-welding tasks and post-processing tasks;

[0042] The intelligent monitoring unit is responsible for the monitoring and control of welding vehicles and auxiliary vehicles, and realizes visual tracking and manual intervention of welding operations;

[0043] The power supply unit is a portable external power supply that provides working power for the welding process and is suitable for field welding operations;

[0044] The welding vehicles are two A and C, and the auxiliary vehicles are two B and D. The interval between the welding vehicles and the auxiliary vehicles is distributed on the outside of the pipeline G, and the adjacent weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com