Process for preparing 4,4'-diaminodiphenylmethane through condensation of acidic ionic liquid catalytic aniline and formaldehyde

A technology of diaminodiphenylmethane and acidic ionic liquid, applied in the field of green chemistry, can solve the problems of difficult reuse of catalyst, high corrosiveness of liquid strong acid, large amount of wastewater discharge, etc., achieves good industrial application prospects, overcomes the post-treatment process Cumbersome, low vapor pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

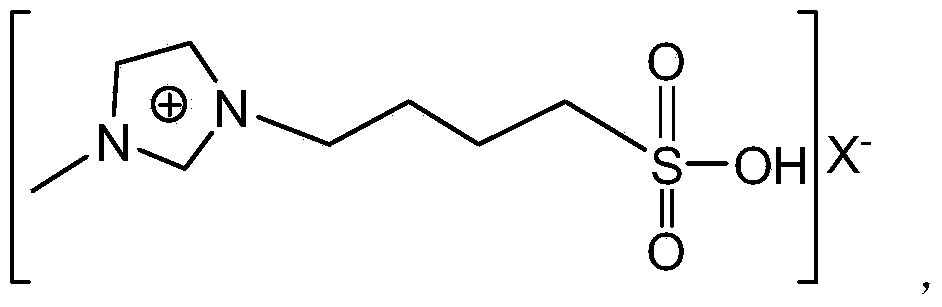

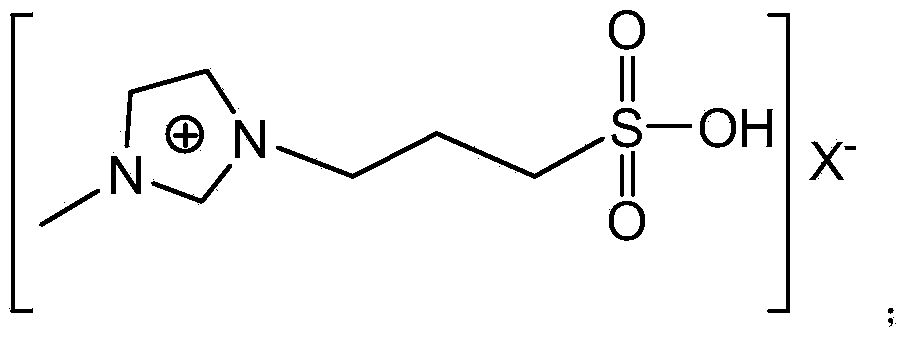

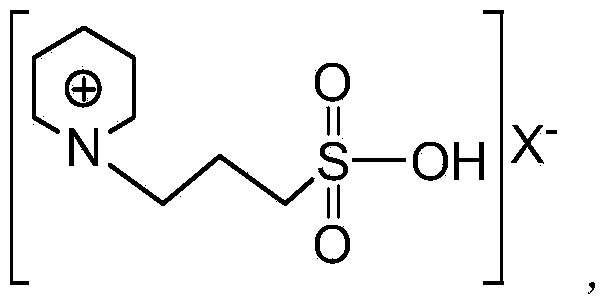

Method used

Image

Examples

Embodiment 1

[0039] In the three-necked flask, add 3.418g [HSO 3 -bmim]C 6 h 6 SO 3 Ionic liquid and 15.331g aniline (0.165mol), magnetically stirred, and 2.634g formaldehyde aqueous solution (mass fraction: 37%, formaldehyde 0.032mol) was added dropwise at 50°C, after the dropwise addition, maintained for 15min, and finally raised to 80°C Reaction 8h. After the reaction was finished, it was cooled to room temperature, and a sample was analyzed by liquid chromatography. The conversion rate of aniline was 33.3%, and the yield and selectivity of 4,4'-MDA were 63.8% and 75.5% respectively (4,4'-MDA Yield is based on formaldehyde, selectivity is based on aniline).

[0040] After the reaction, water was added to the reaction solution for extraction, and the aqueous layer and the organic layer were separated. The aqueous layer was rotatably evaporated, and the ionic liquid was recovered and reused.

[0041] Examples 2-44 were carried out according to the operation steps of Example 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com