Water-based gold ink for tipping paper and preparation method thereof

A water-based technology of tipping paper, applied in inks, applications, household appliances, etc., can solve the problems of copper green and copper powder oxidation reaction, improve printing fastness, highlight safety and environmental protection performance, and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

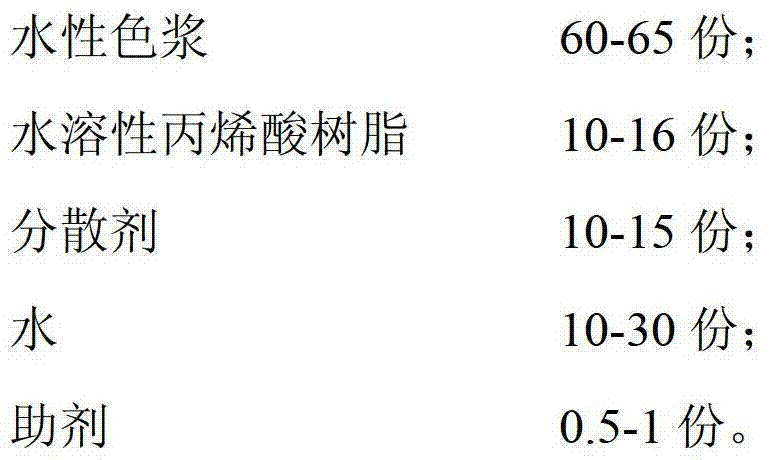

[0035] The formula of water-based gold ink is as follows:

[0036]

[0037] Prepare water-based gold ink as follows:

[0038] 1) Weigh the water-based color paste, water-soluble acrylic resin, dispersant, additives and water according to the formula ratio and grind them finely; during the fine grinding process, the temperature is 60°C, the pH value is 7.0, and the grinding time is 3 hours;

[0039] 2) Mix the raw materials and stir evenly, first add 50% of the polymerization initiator, then raise the temperature under stirring, add the remaining polymerization initiator in batches during the heating process; the total amount of the polymerization initiator added is 0.3%;

[0040] 3) Reaction under reflux conditions for 1.5 hours;

[0041] 4) Focus on controlling the viscosity of the polymer. The viscosity is 160 seconds / 25°C in the No. 4 cup, and the acid value is 45 mgkoh / g. Add ammonia solution for neutralization, and control the final pH value to 8.0;

[0042] 5) Dilut...

Embodiment 2

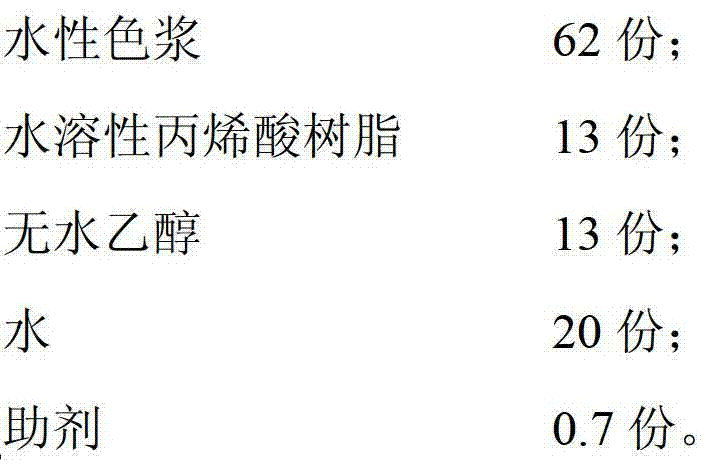

[0047] The formula of water-based gold ink is as follows:

[0048]

[0049] Prepare water-based gold ink as follows:

[0050] 1) Weigh the water-based color paste, water-soluble acrylic resin, dispersant, additives and water according to the formula ratio and grind them finely; during the fine grinding process, the temperature is 65°C, the pH value is 7.0, and the grinding time is 3 hours;

[0051] 2) Mix and stir the raw materials evenly, first add 50% of the polymerization initiator, then raise the temperature under stirring, add the remaining polymerization initiator in batches during the heating process; the total amount of the polymerization initiator added is 0.2%;

[0052] 3) Reaction under reflux conditions for 1.5 hours;

[0053] 4) Focus on controlling the viscosity of the polymer. The viscosity is 170 seconds / 25°C in the No. 4 cup, and the acid value is 40 mgkoh / g. Add ammonia solution for neutralization, and control the final pH value to 8.0;

[0054] 5) Dilut...

Embodiment 3

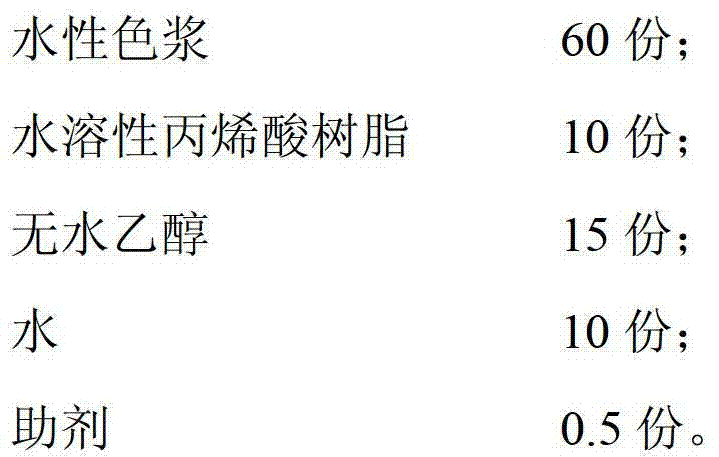

[0059] The formula of water-based gold ink is as follows:

[0060]

[0061] Prepare water-based gold ink as follows:

[0062] 1) Weigh the water-based color paste, water-soluble acrylic resin, dispersant, additives and water according to the formula ratio and grind them finely; during the fine grinding process, the temperature is 55°C, the pH value is 7.0, and the grinding time is 3 hours;

[0063] 2) Mix and stir the raw materials evenly, first add 50% of the polymerization initiator, then raise the temperature under stirring, add the remaining polymerization initiator in batches during the heating process; the total amount of the polymerization initiator added is 0.25%;

[0064] 3) Reaction under reflux conditions for 1.5 hours;

[0065] 4) Focus on controlling the viscosity of the polymer. The viscosity is 150 seconds / 25°C in the No. 4 cup, and the acid value is 50 mgkoh / g. Add ammonia solution for neutralization, and control the final pH value to 8.0;

[0066] 5) Dilu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com