Air valve lift range parameter design method of four-stroke gasoline engine power cycle

A technology of power cycle and valve lift, applied in mechanical equipment, machines/engines, engine components, etc., can solve problems such as large pumping loss, achieve high expansion ratio, and improve cycle thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

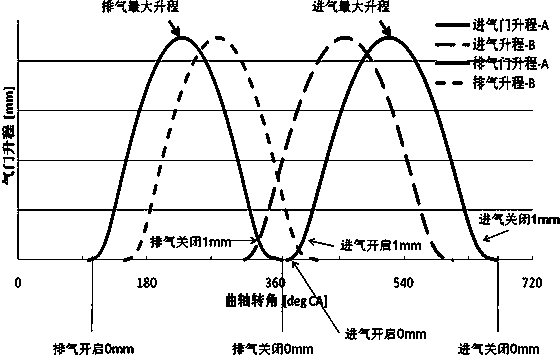

[0028] see figure 1 , "intake valve lift-A" indicates the most retarded position of the intake valve lift, which is also the initial position of the intake valve lift mentioned in the present invention. "Intake valve lift-B" indicates the most advanced position of the intake valve. "Exhaust valve lift-A" indicates the most advanced position of the exhaust valve lift, which is also the initial position of the exhaust valve lift mentioned in the present invention.

[0029] The exhaust valve lift is close to the position of "exhaust valve lift-B" and the intake valve lift is close to the position of "intake valve lift-A" under light load, so as to improve the thermal efficiency of the cycle. As the load increases, the exhaust valve lift moves from "exhaust valve lift-B" to "exhaust valve lift-A", and the intake valve lift moves from "intake valve lift-A" to " Intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com