Electronic shifting system of vehicle mechanical gearbox

A mechanical gearbox and electronic shifting technology, applied in the field of auto parts, can solve the problems of low transmission efficiency and slow power response, and achieve the effects of large transmission torque, fast response, and improved shifting smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

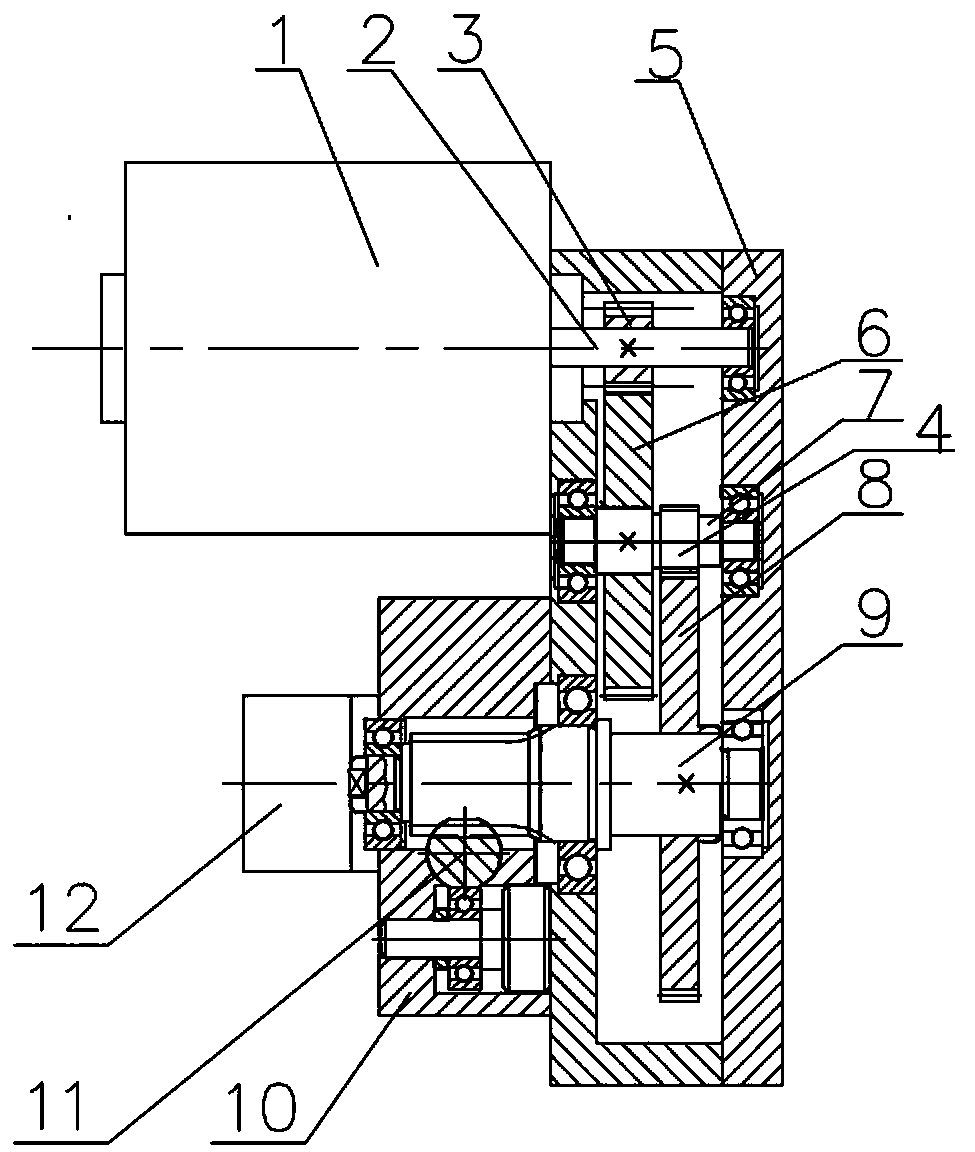

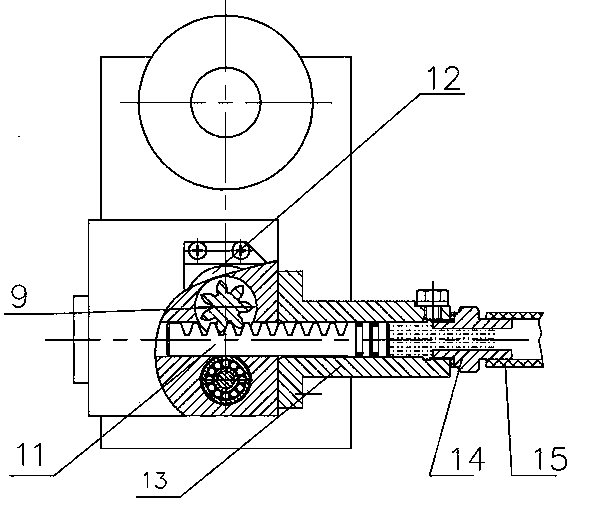

[0022] Attached below Figure 1-5 The specific implementation manner of the present invention will be further described.

[0023] The power transmission structure in the technical solution of the present invention is the same as the power transmission structure of the manual gearbox, that is, the power transmission is transmitted from the engine to the transmission, and then to the output component, realizing the direct transmission of power.

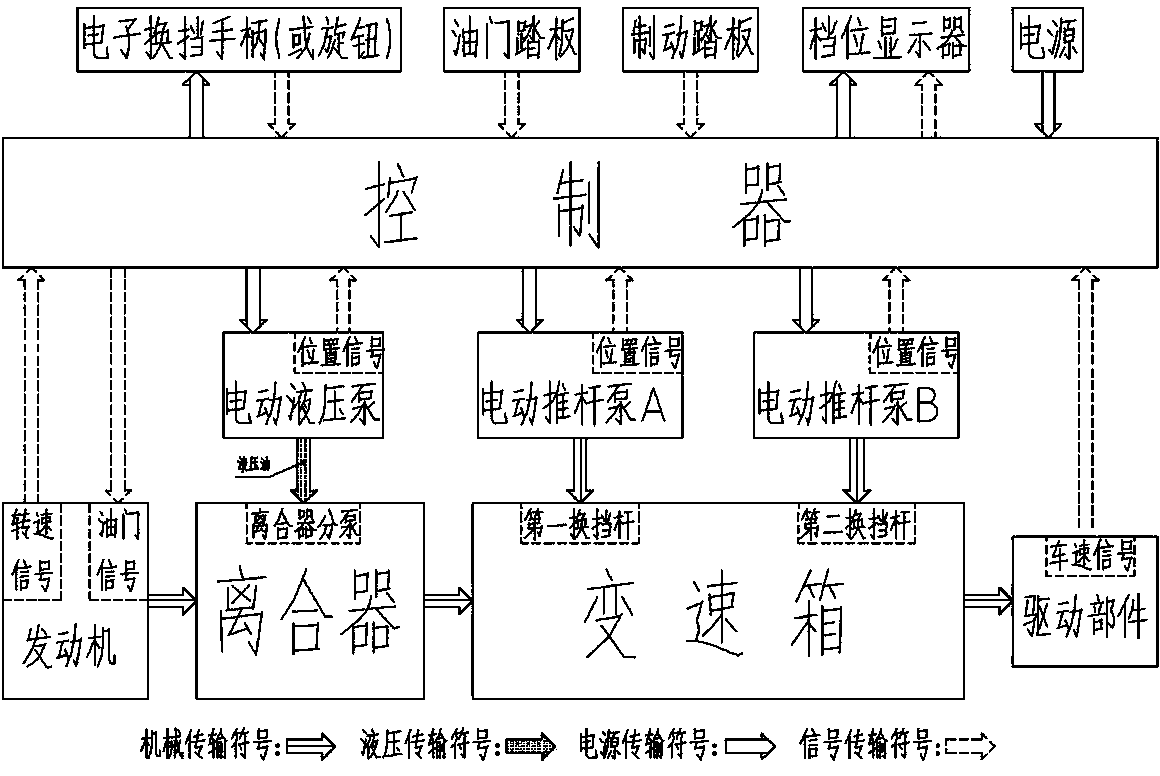

[0024] Such as figure 1 As shown, the control schematic diagram of the electronic shift system,

[0025] An electronic shifting system of a mechanical gearbox for a vehicle, the electronic shifting system of the mechanical gearbox includes a controller, an electric hydraulic pump, an electric push rod pump A, an electric push rod pump B, a gear display, an electronic shift handle or Electronic shift knob, brake pedal, power supply, clutch, gearbox, drive components, engine.

[0026] The power supply provides power for the controller,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com