Light emitting diode detection measuring tool

A technology for light-emitting diodes and measuring tools, applied in the field of general-purpose measuring tools, can solve the problems of loss of reproducibility of light-emitting diode light sources 203, large differences in luminous flux values, and lack of applicability, so as to improve long-term reliability, improve detection quality, and simplify manufacturing processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

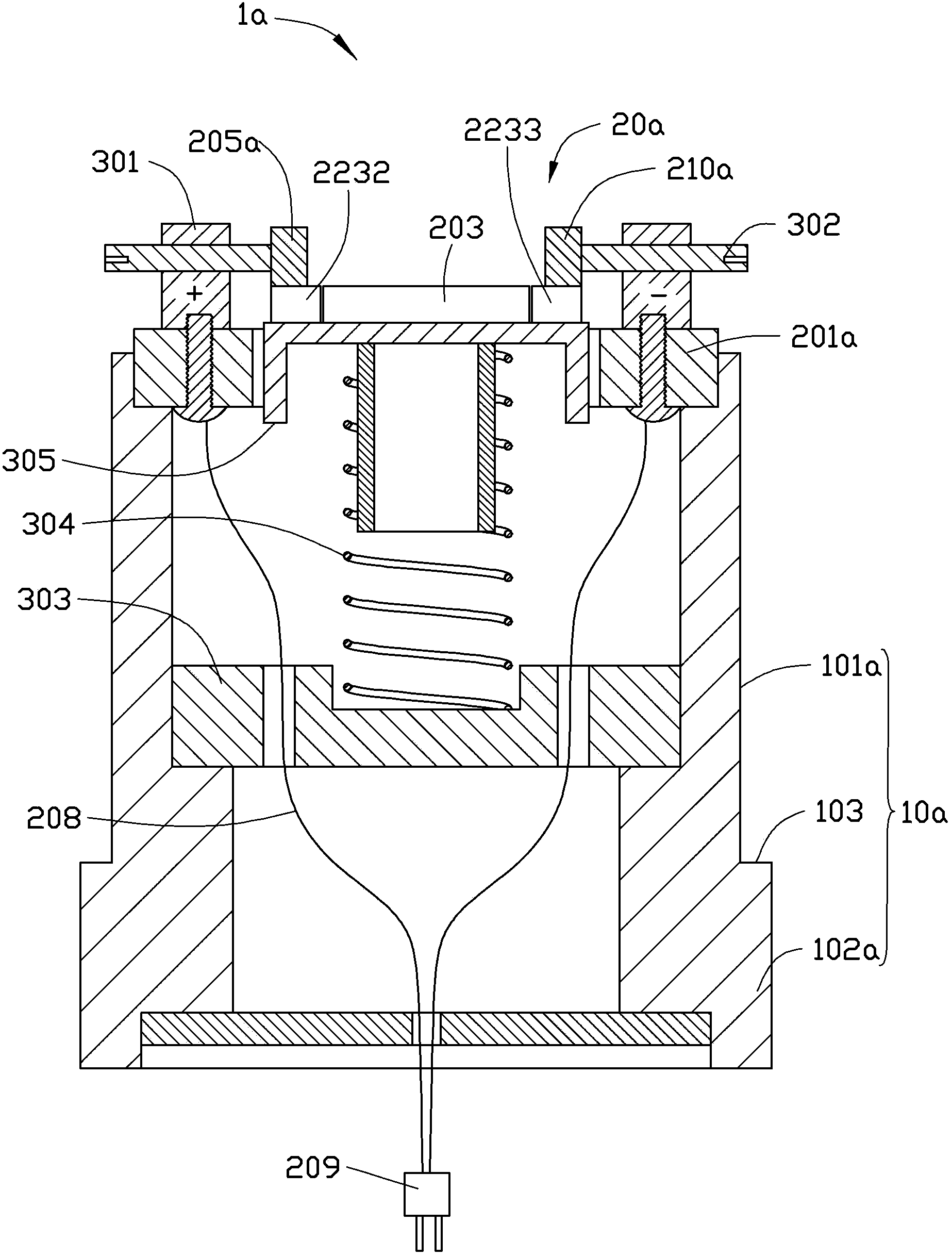

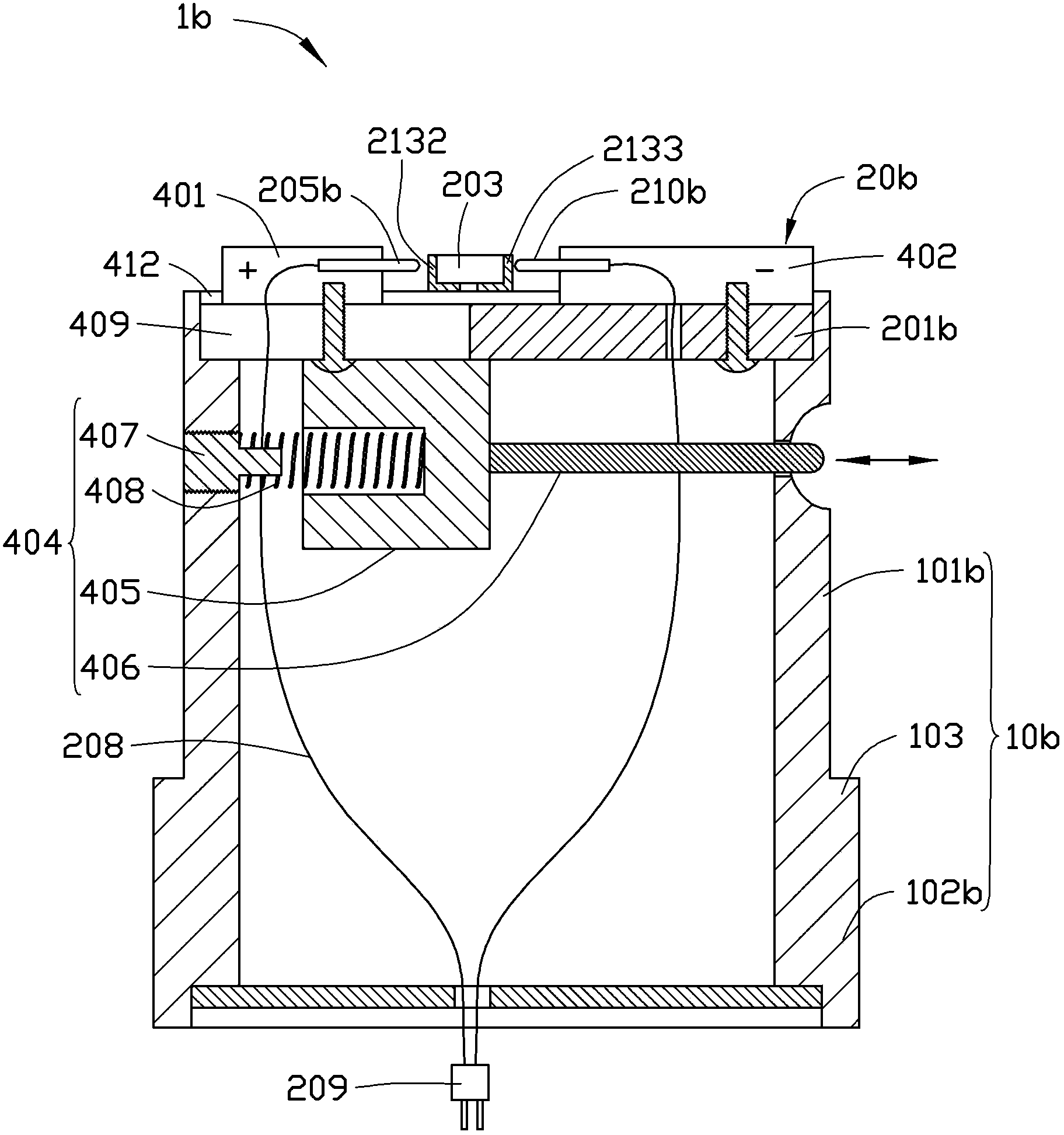

[0078] Refer to the following Figure 4 Turning to FIG. 9 , the universal measuring tool for detecting light-emitting diodes of the present invention is further described.

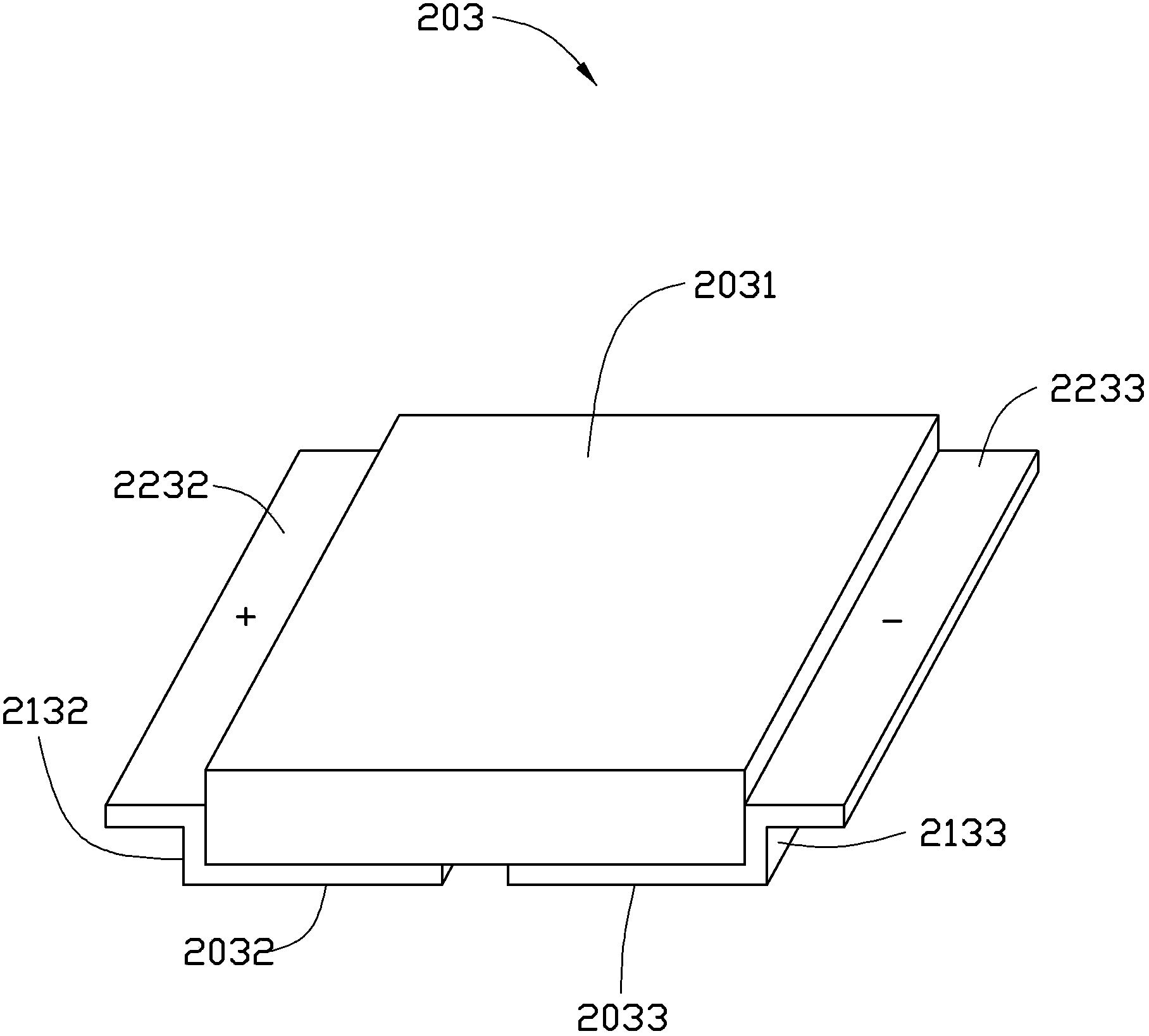

[0079] Figure 4 It is a schematic cross-sectional view of the assembly of the first embodiment of the present invention, Figure 5A and Figure 5B respectively Figure 4 The top and bottom perspective views of the test department in the center, Figure 6 for Figure 4 Schematic diagrams of the two telescopic assemblies in Figure 7A and Figure 7B respectively Figure 4 The schematic diagram of the two kinds of electrodes;

[0080] The shell portion 10 is a hollow cylinder with an opening at least towards one end to install the test portion 20. The outer peripheral wall of the cylinder extends axially from the opening to form a thinner front section 101 and is formed between the remaining thicker rear section 102 walls. Right-angled step surface 103; the outer peripheral wall surface size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com