Compression specially-shaped optical fiber compound aerial phase line

A technology of optical fiber composite and phase wire, which is applied in the direction of power cables, electrical components, circuits, etc., can solve the problems of large cross-sectional area of optical fiber composite overhead phase wire, general self-damping performance, and easy damage of phase wire, etc., to achieve smooth surface and self-damping Good damping performance, the effect of increasing the operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail according to the examples below.

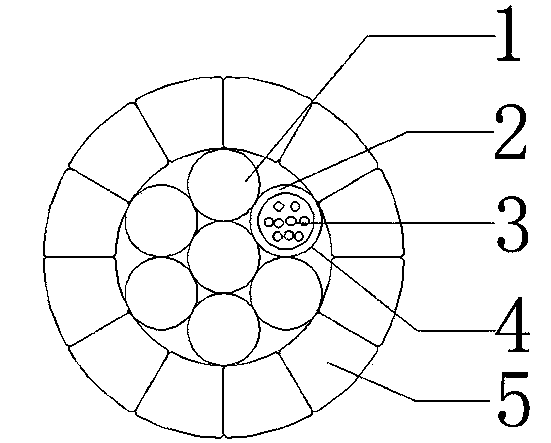

[0016] Such as figure 1 As shown, a compact special-shaped optical fiber composite overhead phase line includes a core, an optical fiber unit 4 composed of an optical fiber 3 and a stainless steel sleeve 2 surrounding the outer surface of the optical fiber, a round aluminum-clad steel wire 1 and a fan-shaped hard The aluminum wire 5 is surrounded by a first cladding layer composed of an optical fiber unit 4 and a plurality of round aluminum-clad steel wires 1, and a multi-strand fan-shaped duralumin is surrounded on the outside of the first cladding layer. The second cladding layer composed of wire 5. Each strand of the phase line is in surface contact with each other, and the wire core, the first covering layer and the second covering layer are arranged concentrically.

[0017] Compared with the ordinary optical fiber composite overhead phase wire, under the condition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com