Metering unit

A technology for measuring components and liquid flow, applied in the direction of flow control, special packaging objects, non-electric variable control, etc., can solve the problems of unreliability, large amount of bacteria in food, inaccurate measurement, etc., and achieve the effect of compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

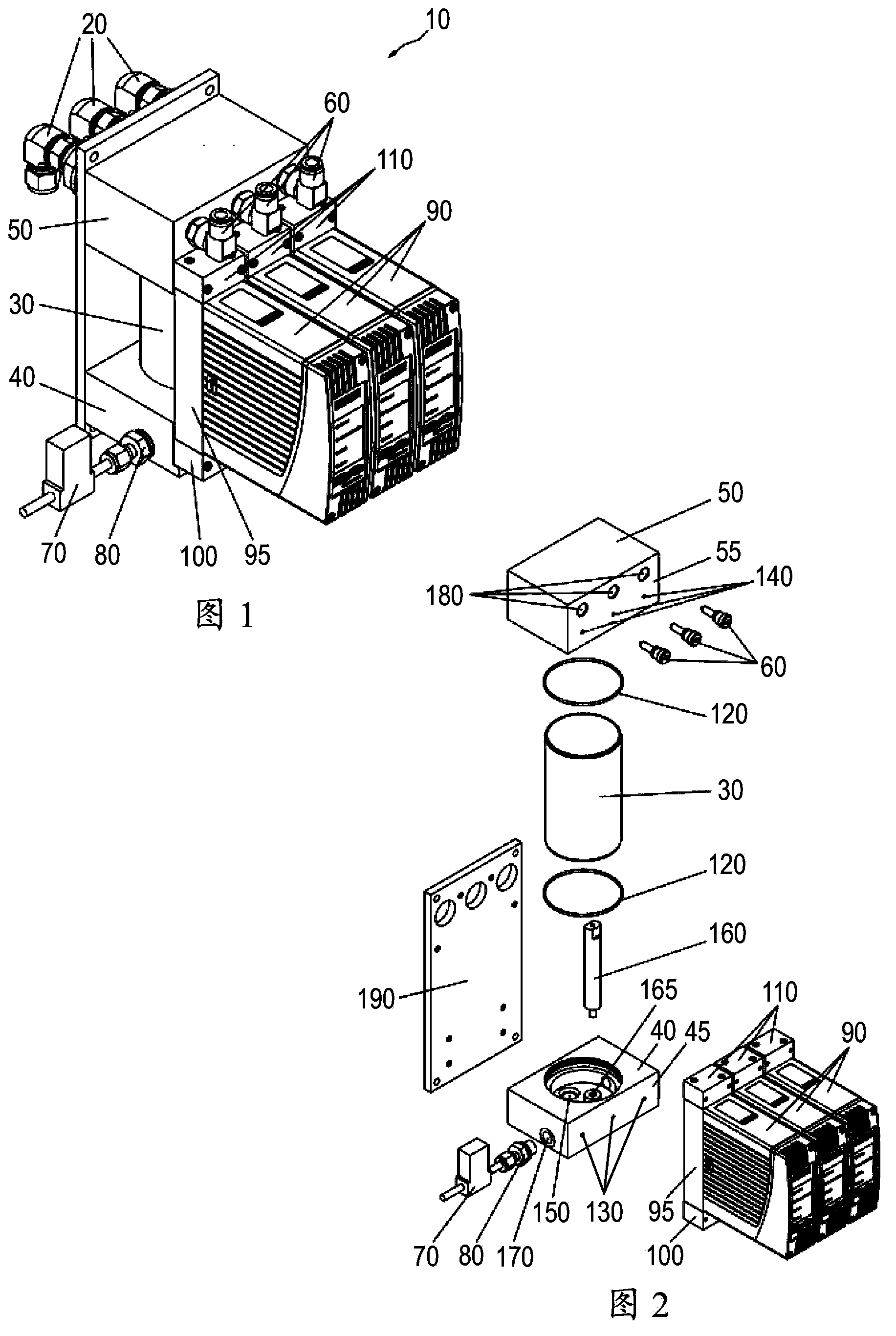

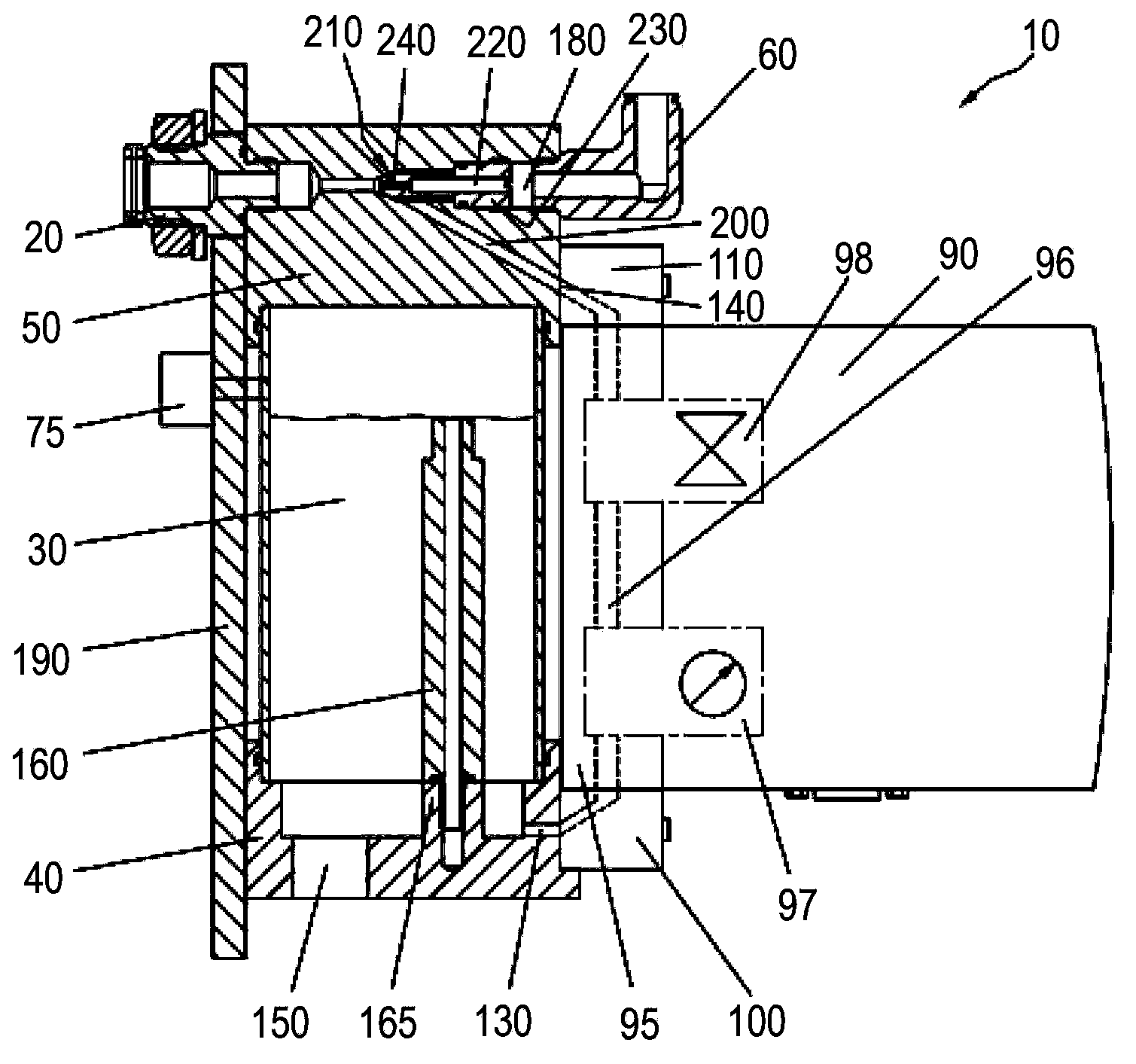

[0034] figure 1 It is shown that the metering assembly 10 for preparing aerosols has three outlets 20. A common buffer container 30 for receiving liquid is arranged between the first carrier module 40 at the bottom and the second carrier module 50 at the top, the liquid being a component of the aerosol to be metered.

[0035] The two carrier modules 40, 50 are generally rectangular monolithic parts shaped so as to be parallel to each other.

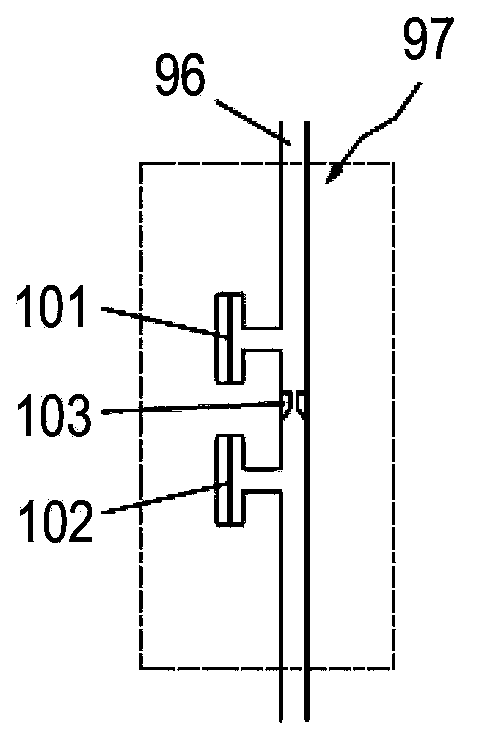

[0036] The carrier gas is supplied via the connector 60 on the carrier module 50, and the liquid for forming aerosol is mixed into the carrier gas (in image 3 Detailed in).

[0037] The first carrying module 40 has a port 80, and a pressure reducing valve 70 for controlling the pressure in the buffer container 30 is connected to the port 80.

[0038] The three liquid flow controllers 90, each formed as a structural component, each have a fluid block 95, and the three liquid flow controllers 90 are fixed to one end 100 of the fluid block 95 by me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com