Thin layer drying method and drying equipment

A technology for thin-layer drying and drying equipment, applied in separation methods, chemical instruments and methods, evaporator accessories, etc., can solve the problems of high energy consumption and poor drying effect, and achieve energy saving, good use effect, and improved efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

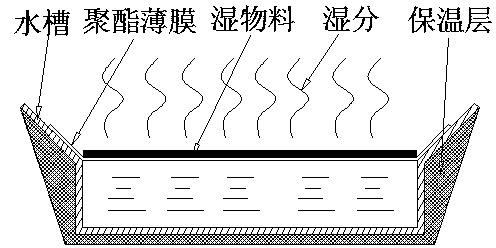

[0019] Such as figure 1 It is a schematic diagram of the present invention, a thin layer drying method:

[0020] a. Add water at 0°C-100°C to the water tank;

[0021] b. Cover the surface of the water in the tank with a polyester film;

[0022] c. Spread the wet material to be dried evenly on the surface of the polyester film;

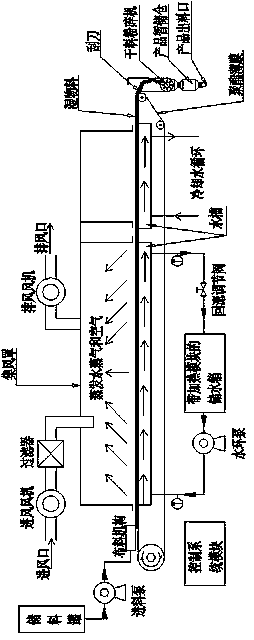

[0023] Such as figure 2 It is a schematic diagram of the equipment structure of the present invention:

[0024] A drying device for implementing the above-mentioned thin-layer drying method, including a conveying system module, a feeding module, a drying module, a cooling module, a receiving module and a control system module.

[0025] According to another embodiment of the present invention, it further includes that the carrier of the delivery system module is a polyester film, and the polyester film is processed into an endless belt.

[0026] According to another embodiment of the present invention, it further includes that the feeding module i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap