Grating screw squeezing and separating machine

A technology of screw pressing and screw separation, applied in the field of water treatment, can solve the problems of large floor area, high investment cost, long process flow, etc., and achieve the effect of low cost, small equipment volume and high separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

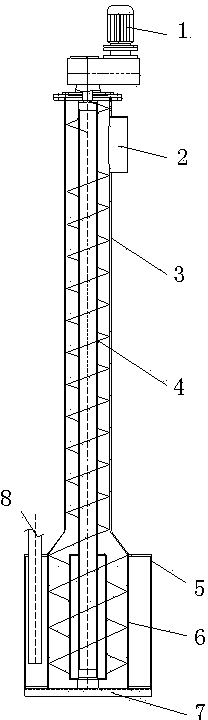

[0010] Such as figure 1 As shown, it includes a driving device 1, a screw separation press conveying part, a liquid collection cylinder 5, and a filter grid cylinder 6. The spiral separation press conveying part includes a screw 4 and a screw separation press conveying set on the outside of the screw 4. Cylinder 3, the upper end of the spiral separation press conveying cylinder 3 is provided with a slag outlet 2, the lower end is fixedly connected with the filter grill cylinder 6, the upper part of the screw 4 is connected with the driving device 1, and the lower end extends into the In the filter grill cylinder 6, the spiral 4 part located in the filter grid cylinder 6 is in clearance fit with the filter grill cylinder 6. The diameters of the two are relatively close, which can collect and transport solid waste to the greatest extent. The diameter of the screw 4 part in the filter grid cylinder 6 is larger than the diameter of the screw 4 part in the screw separation press co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com