Small-scale screening device

A screening device and small-scale technology, which is applied in the direction of screening, solid separation, grille, etc., can solve the problems of unsuitable screening purposes for small production, easy blockage of screen holes, and low production efficiency, so as to reduce operating costs and prevent material Splash, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

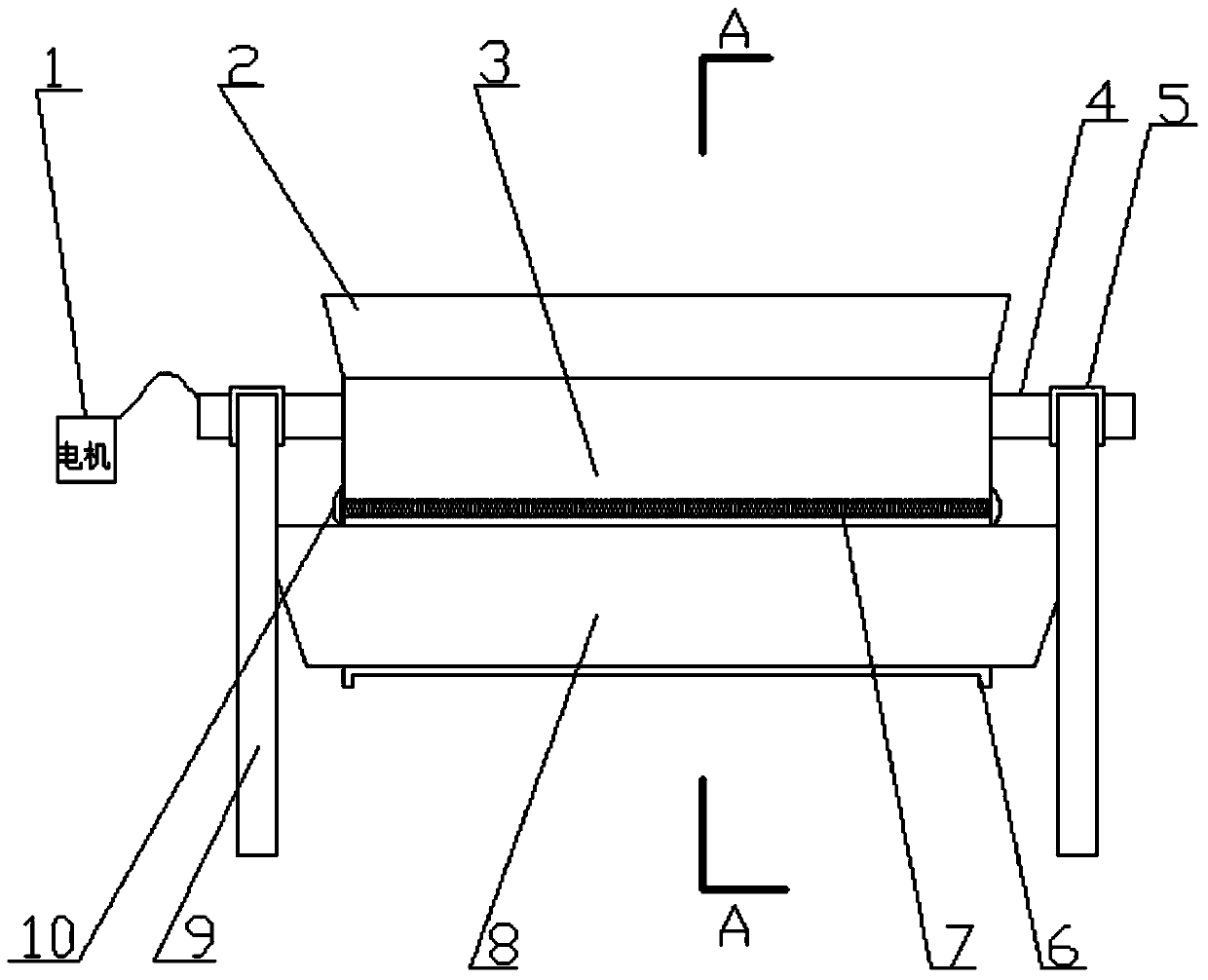

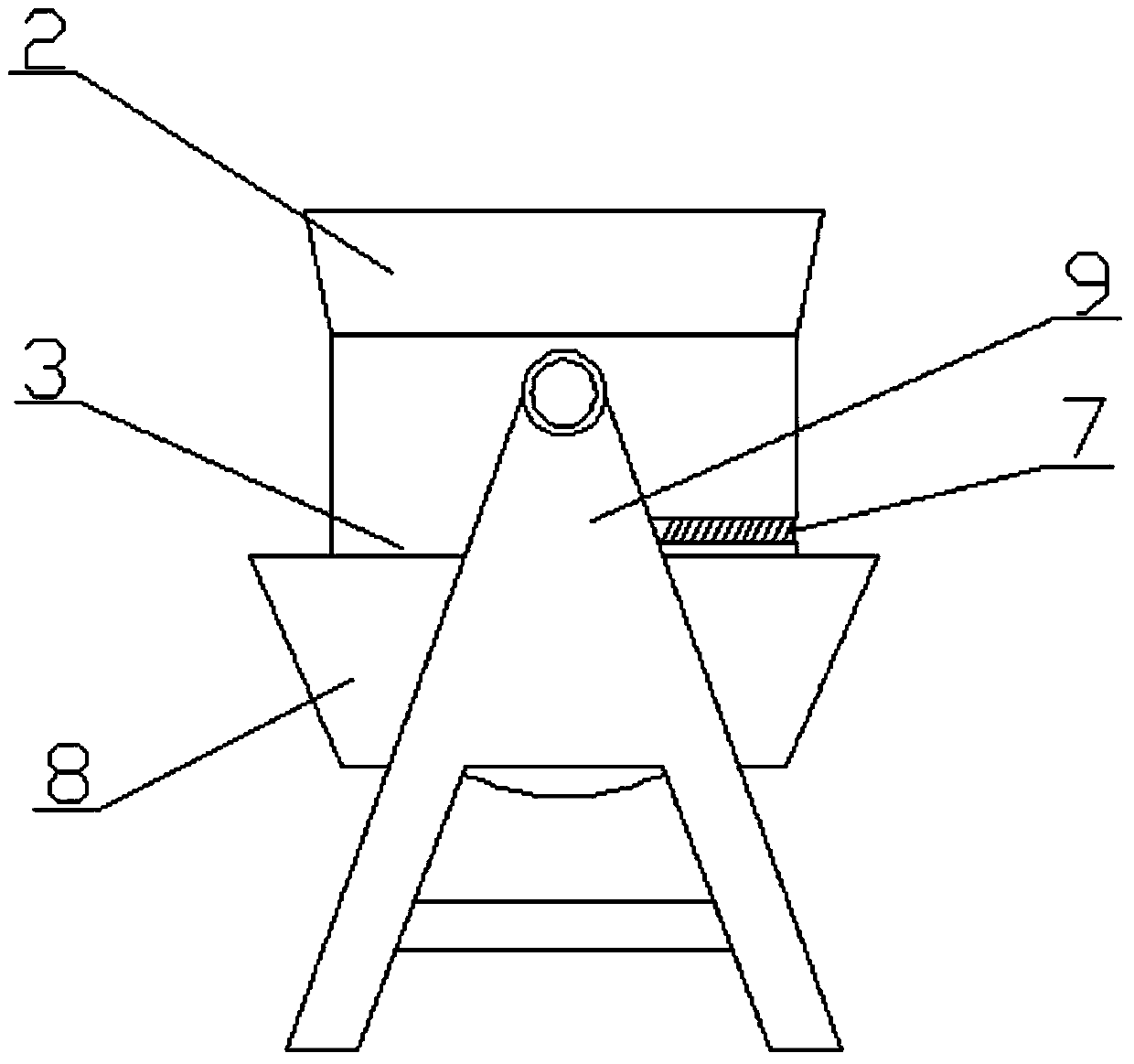

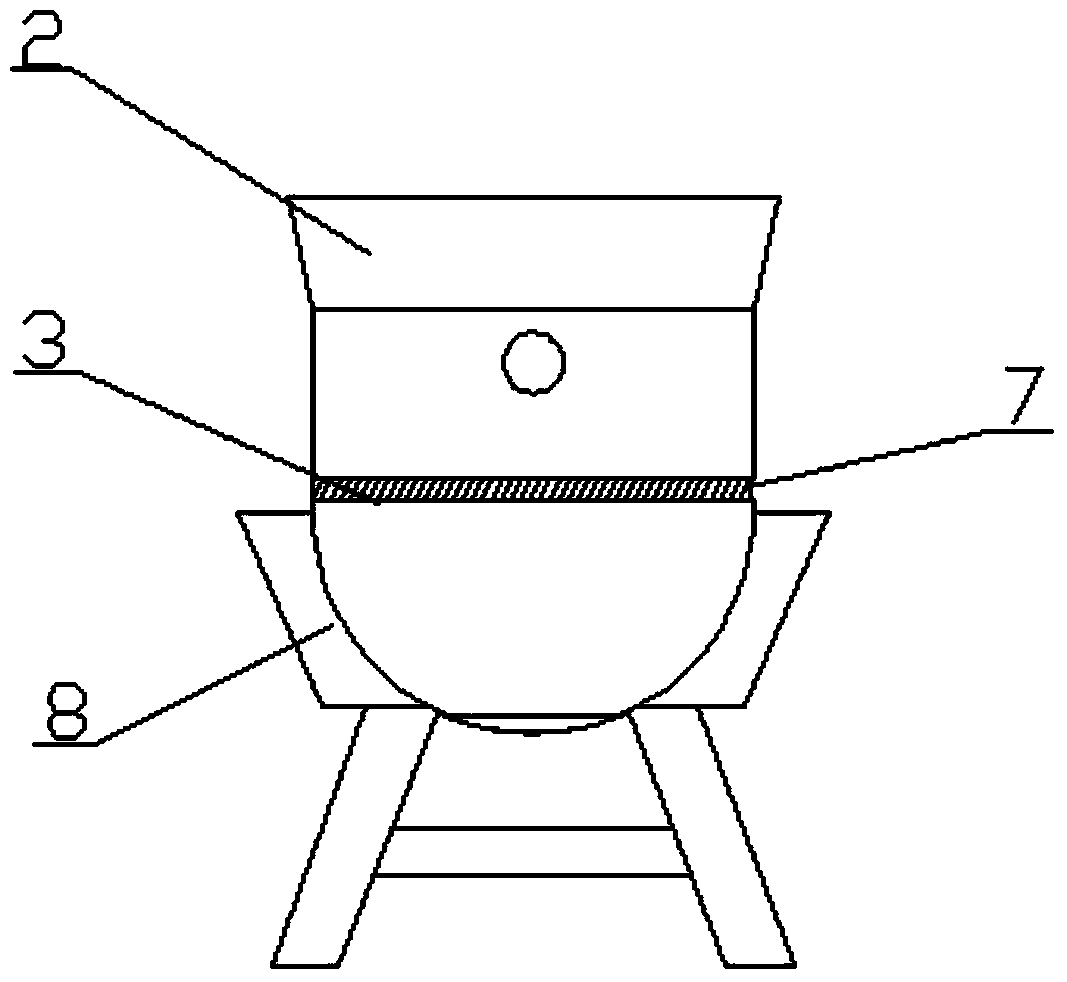

[0019] The present invention will be further described below in conjunction with the accompanying drawings. like figure 1 As shown, the rotating shaft 4 passes through the inside of the screening tank 3, and is connected with the bracket 9 through the bearing 5. The material inlet 2 is in an open shape, and raw materials are scattered on the screen 7 through the inlet 2. The screen 7 is located in the middle of the screen trough 3, and it enters horizontally from the slender rectangular opening on the side of the screen trough 3 during installation. Fix the whole screen frame, and the outlet baffle plate 8 is fixed on the support 9. The motor 1 is connected to the rotating shaft 4 through a line. According to the amount of material on the screen 7, the rotation speed of the rotating shaft 4 is adjusted through the motor 1, and then the amplitude and frequency of the left and right swing of the screening tank 3 are driven, so that the materials on the screen 7 are left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com