Angle milling head with double-lead worm and worm gear transmission anti-backlash device

A technology of worm gear transmission and double leads, which is applied in the direction of milling machine equipment, manufacturing tools, milling machine equipment details, etc., to achieve the effect of ensuring smoothness, small equipment occupation space, smooth and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

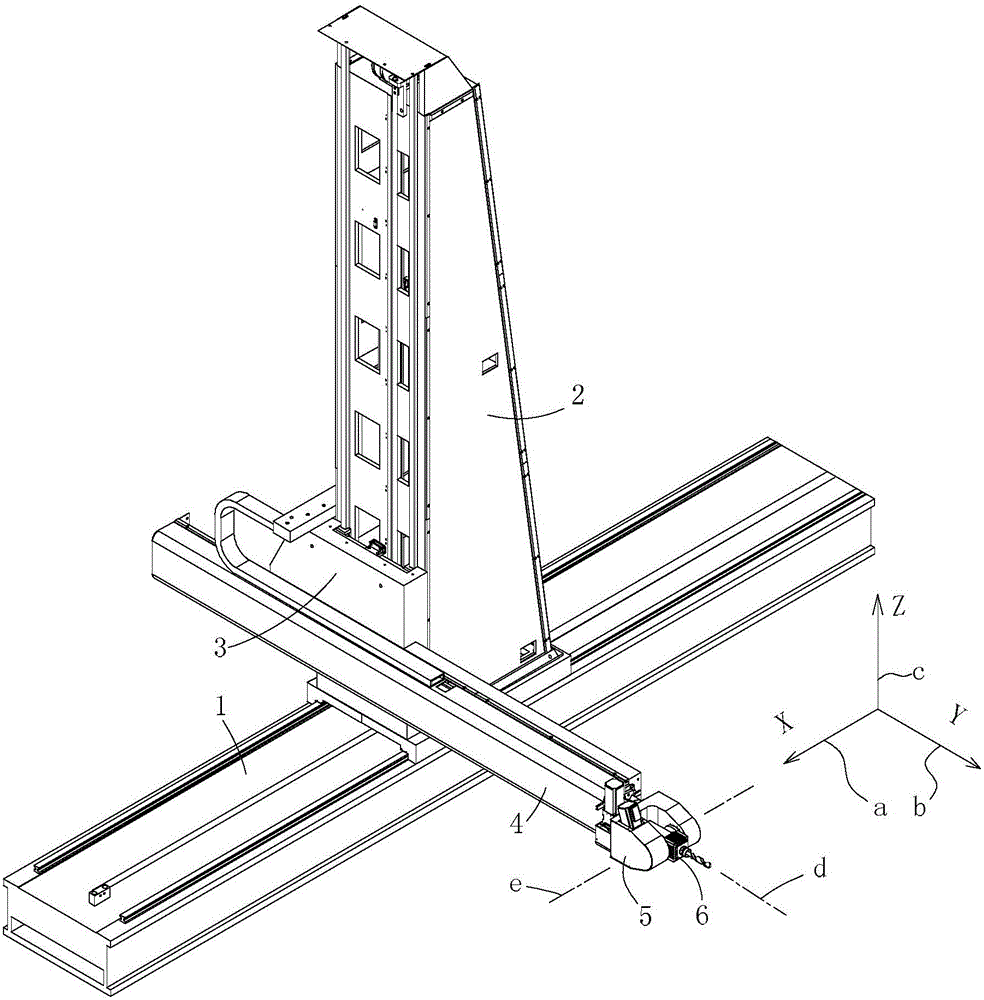

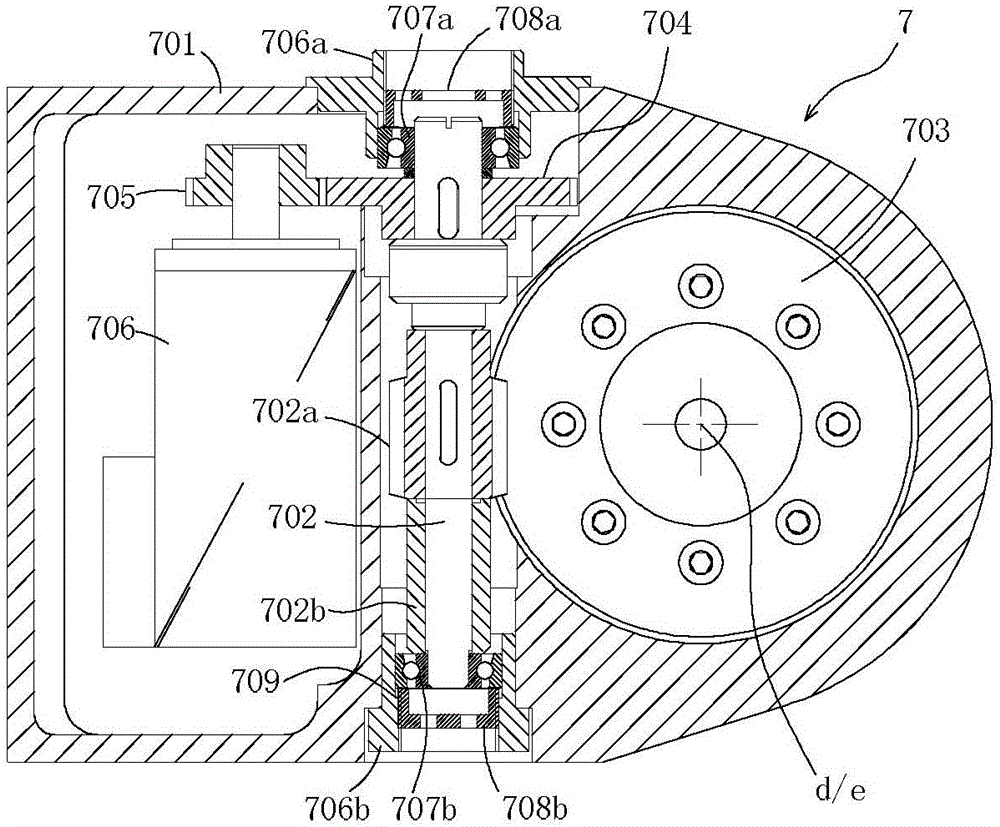

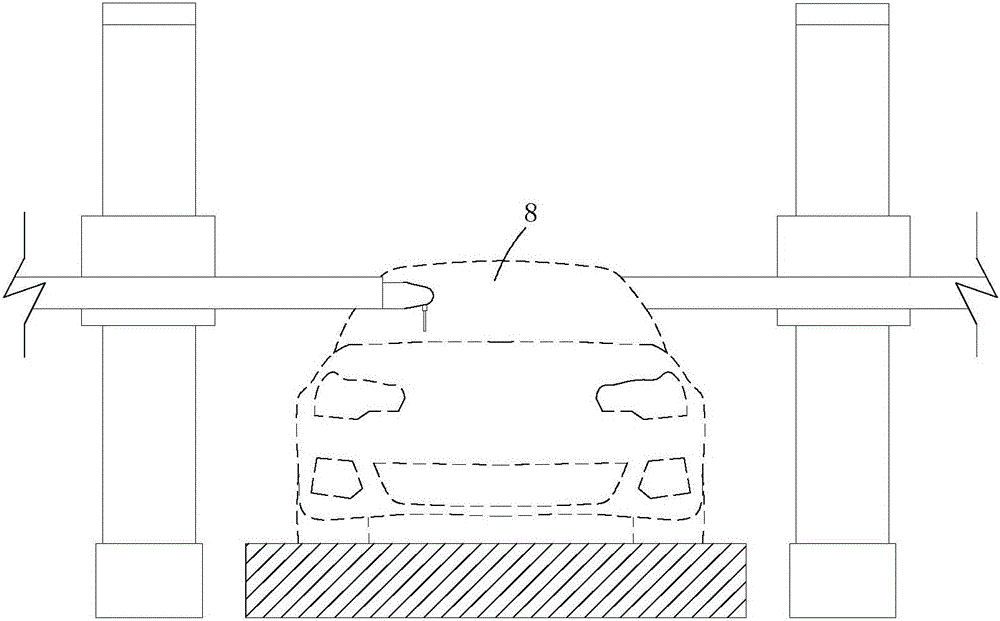

[0027] Such as figure 1 As shown, the three-dimensional soft model cutting and forming machine includes: a base 1; a column 2, the column 2 is installed on the base 1 through the first guiding driving mechanism and can reciprocate along the horizontal X-axis a under the support of the first guiding driving mechanism ; fixed cantilever 3, said fixed cantilever 3 is installed on the column 2 by the second guide drive mechanism and can reciprocate along the vertical Z-axis c under the maintenance of the second guide drive mechanism; movable cantilever 4, said movable cantilever 4 is installed on the fixed cantilever 3 through the third guide drive mechanism and can reciprocate along the horizontal Y-axis b under the support of the third guide drive mechanism; the angle milling head base 5, the angle milling head base 5 passes through the fourth guide The driving mechanism is installed on the front end of the movable cantilever 4 and can swing bidirectionally around the first refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com