Novel assembling and welding process of spiral shaft of high-weir type double-spiral classifier

A double helix and classifier technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as large vibration, large noise, and poor manufacturing accuracy of the screw shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

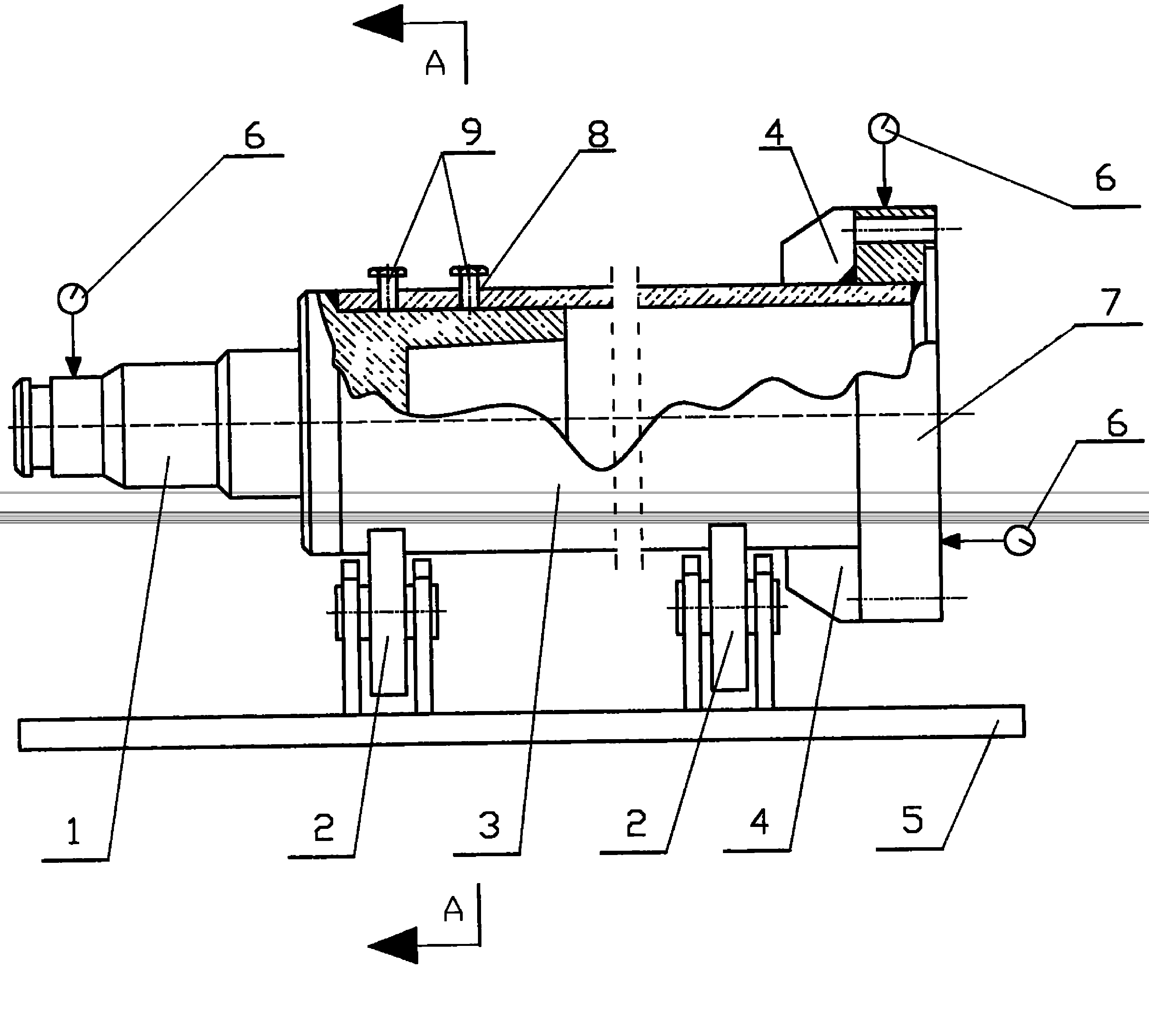

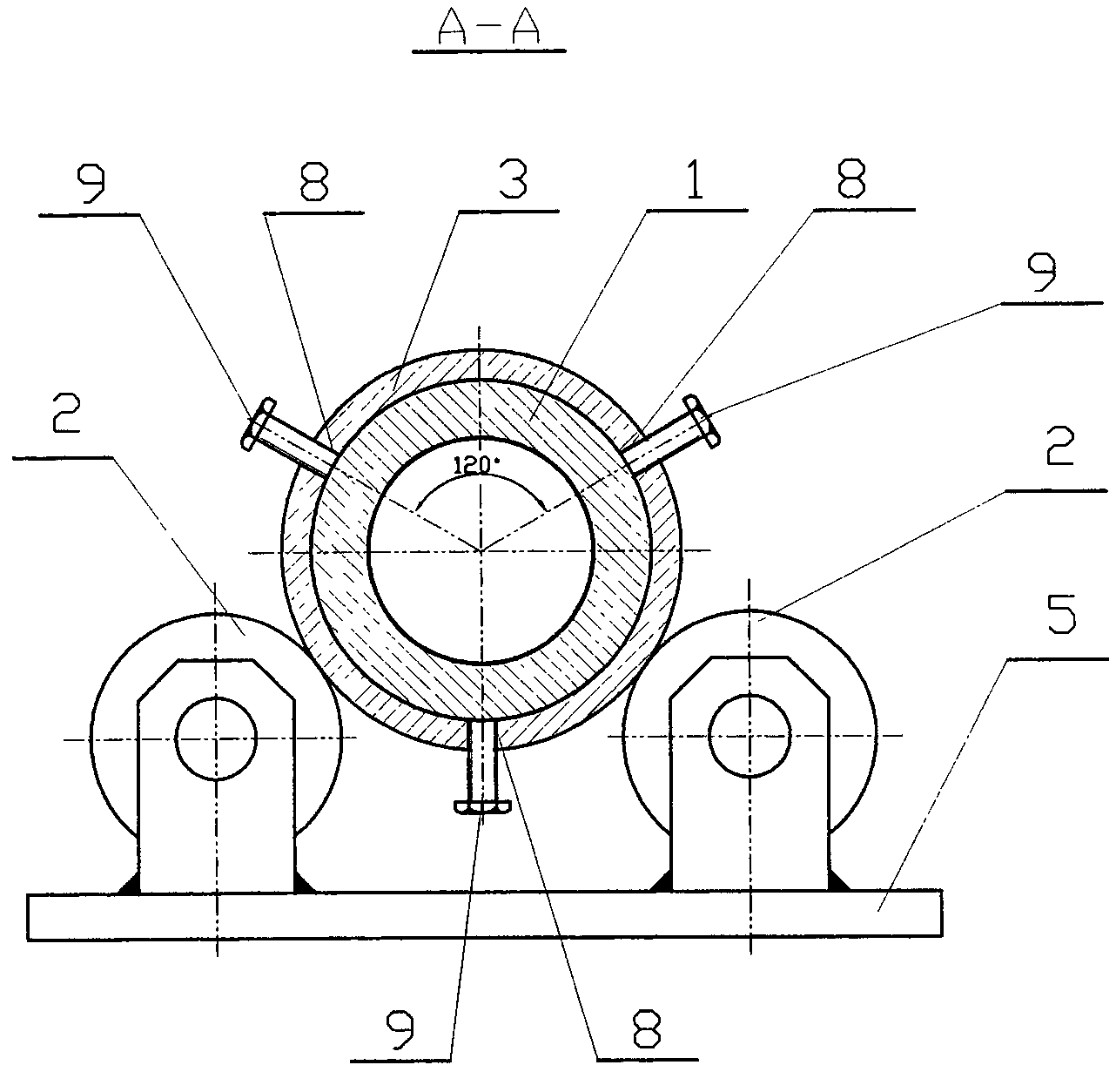

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

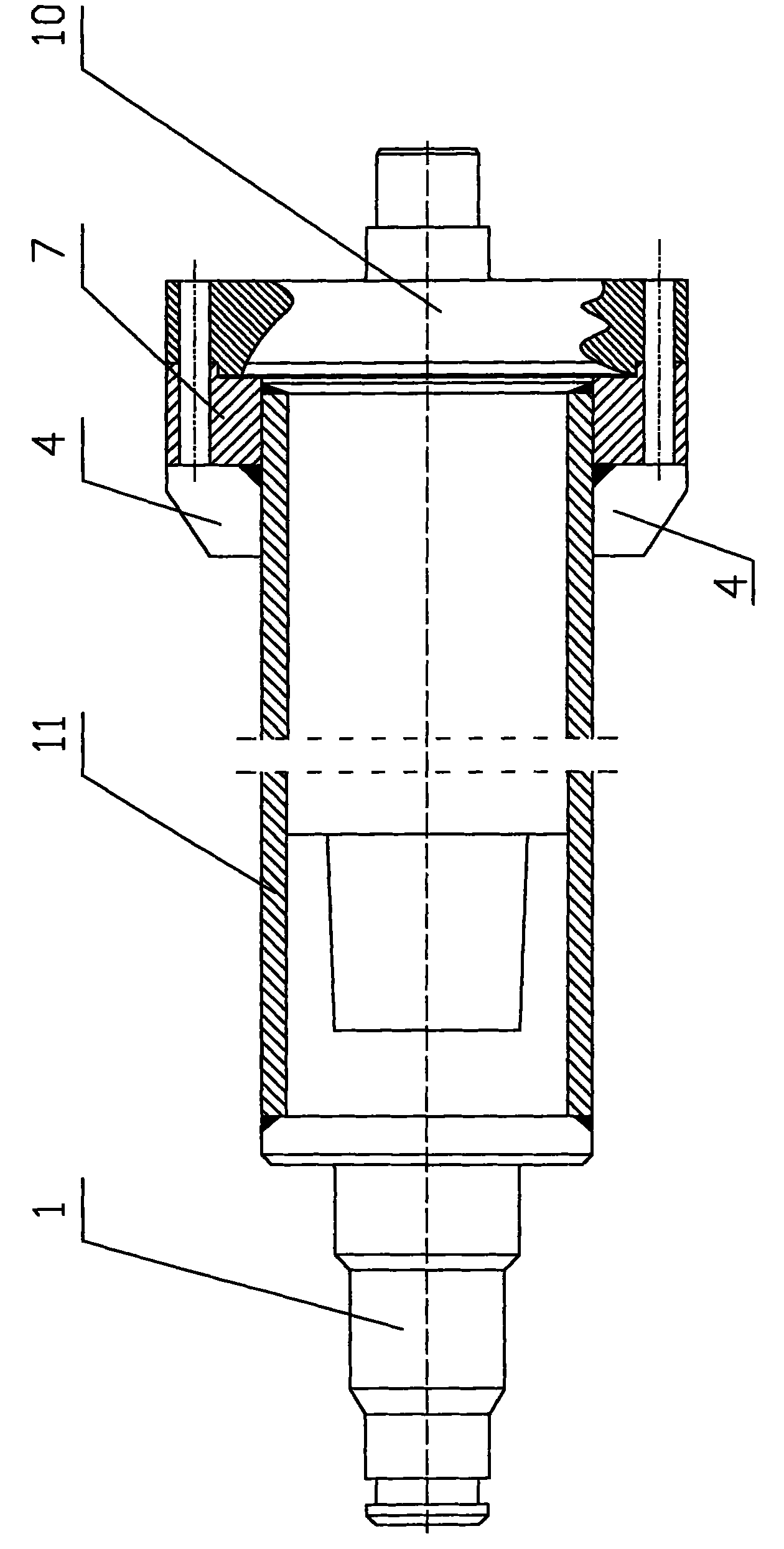

[0012] refer to image 3 , the screw shaft of the high weir double-screw classifier is mainly composed of three parts: journal 1, hollow shaft 11, and tail shaft 10. Perform precision machining. Then the journal 1 and the hollow shaft 11 are assembled and welded into one, the reinforcing rib 4, the flange 7 and the hollow shaft 11 are welded into one and then precision machining is carried out, and the tail shaft 10 is assembled with the flange 7 with bolts. This traditional manufacturing process is labor-intensive and time-consuming, which makes the manufacturing cost of the screw shaft high, and it is difficult to ensure high manufacturing accuracy after processing. The main difficulty in manufacturing is that the screw shaft is very long and heavy. After welding and assembly, due to the misalignment of the manufacturing benchmark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com