Parallel scanning laser preprocessing device and method

A preprocessing device and scanning laser technology, applied in the field of optics, can solve the problems of uncontrollable component preprocessing, uneven irradiation, and inability to monitor scanning points in real time, compressing the preprocessing time period, and solving uneven reflected irradiation. , The effect of raising the laser damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is further described.

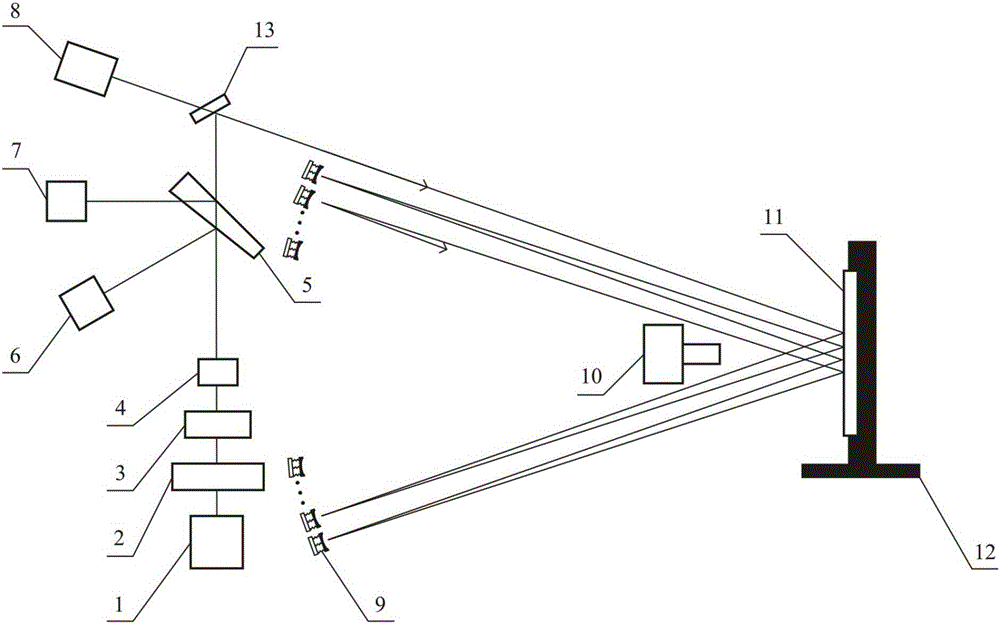

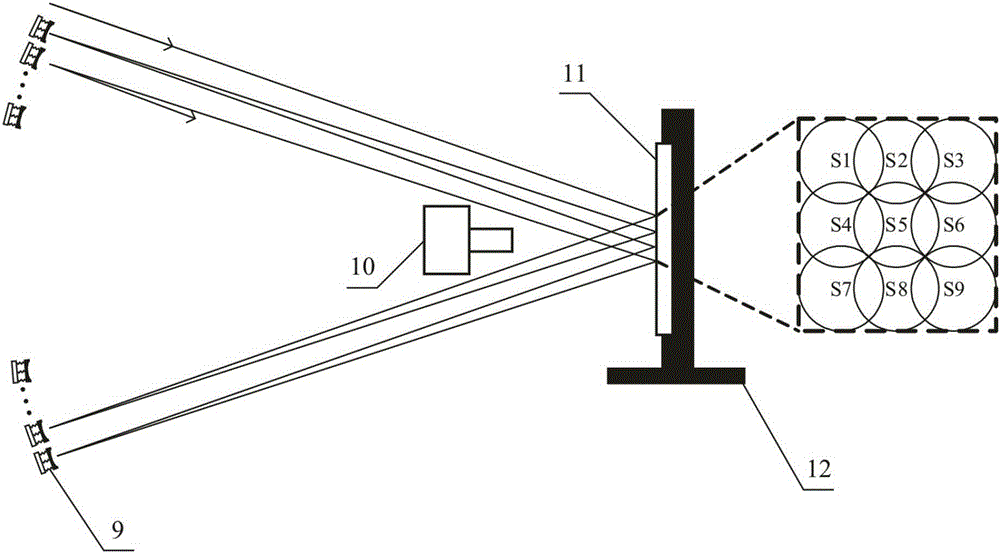

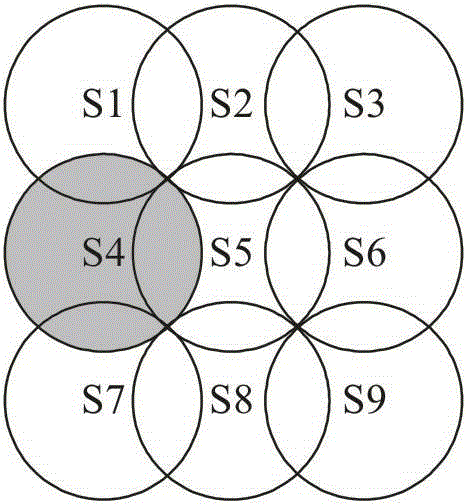

[0024] see figure 1 ---4, parallel scanning laser preprocessing device, including laser light source 1, mechanical shutter 2, energy attenuator 3, beam converging system 4, beam splitter 5 and beam combiner 13 arranged along the laser transmission direction, and also includes a beam profiler 6. Laser energy meter 7, beacon light source 8 and electric displacement stage 12; optical element 11 is placed on electric displacement stage 12; a tilting mirror array 9 is arranged between the device and optical element 11, and a detection camera is arranged in front of optical element 11 10.

[0025] The laser light source 1 is a Q-switched solid-state laser. The beacon light source 8 is a helium-neon laser. The mirror surface of the tilting mirror array 9 is a concave mirror coated with a high reflection film.

[0026] The angle (degree of freedom) control of the tilting mirror array 9 is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com