Production method of plug for paper tube

A plug and paper tube technology, applied in the field of plug preparation, can solve problems such as low pressure bearing capacity, and achieve the effects of improving pressure bearing capacity, prolonging service life and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

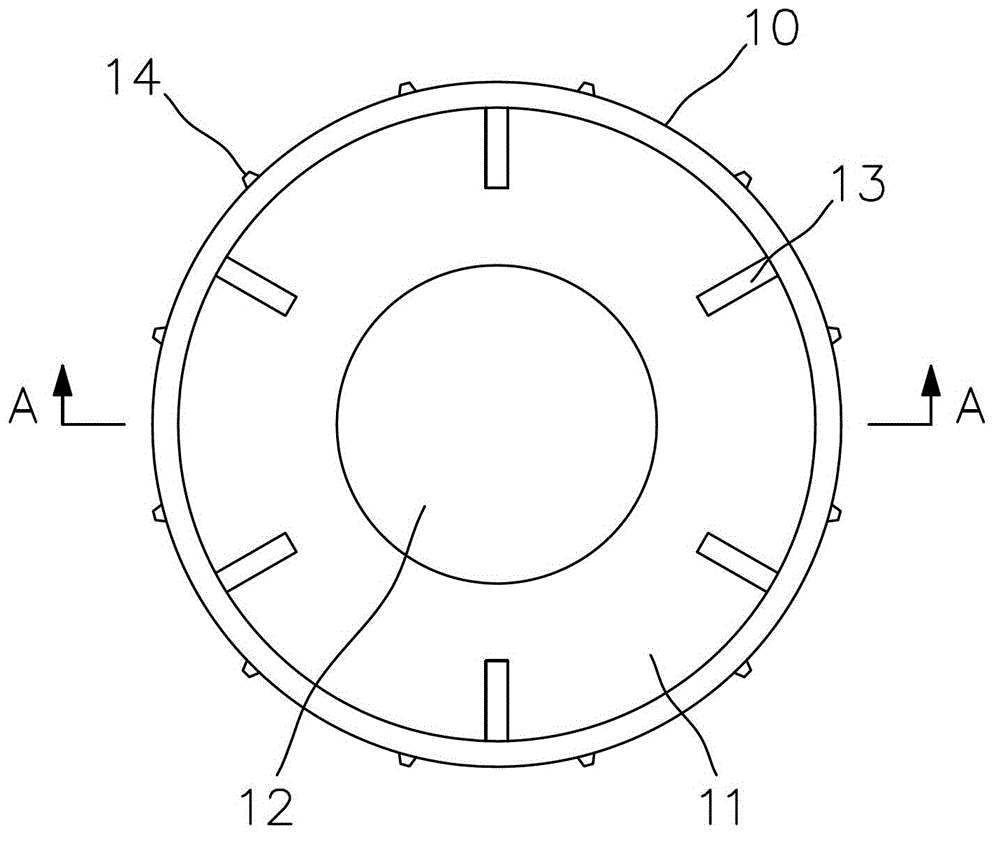

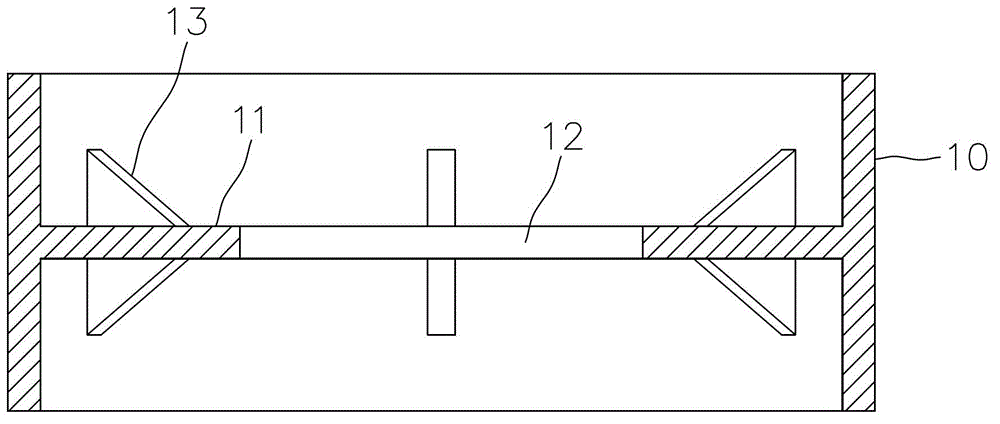

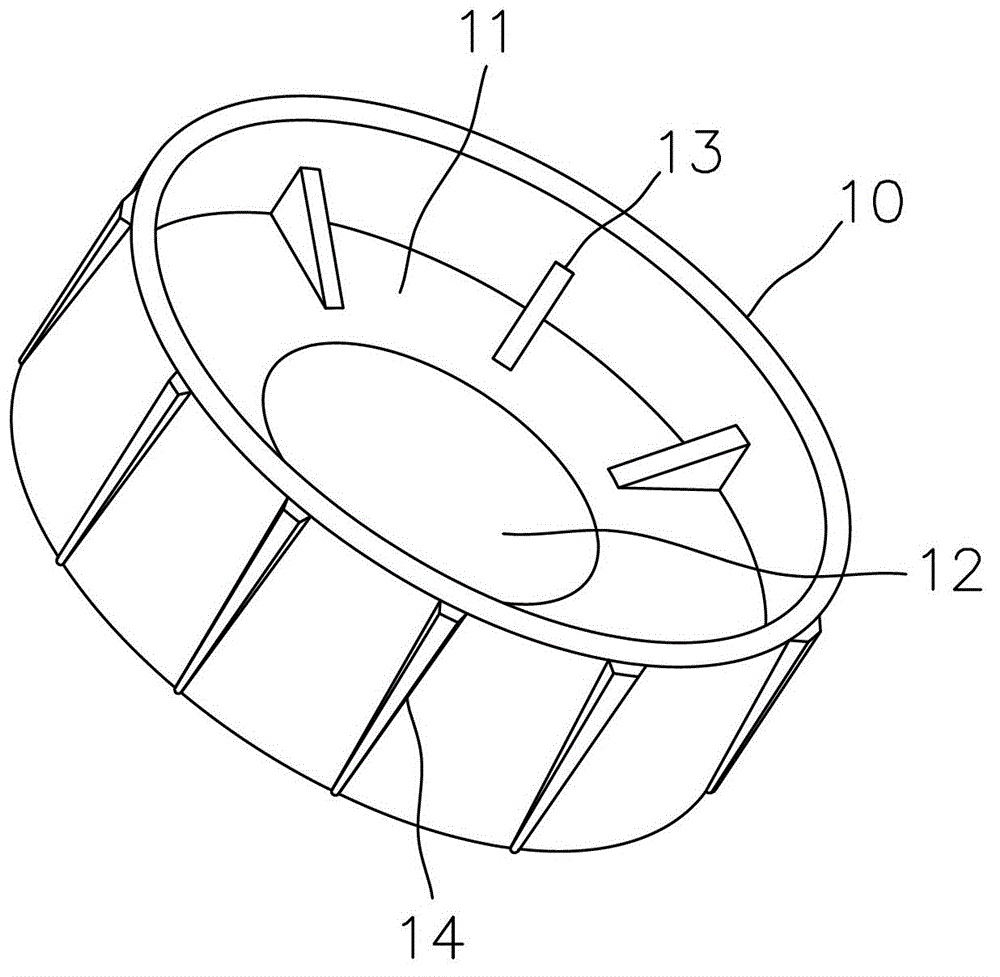

Image

Examples

Embodiment 1

[0042] First of all, directly purchase polyethylene, cast polypropylene film and color masterbatch from the market. Then, complete the steps as follows:

[0043] Step ①. Mix polyethylene, cast polypropylene film and color masterbatch according to the weight ratio of 1:1:0.016, mix and stir evenly, and add it to the hopper of the injection molding machine, heat to 195°C, and keep the heating time for 8 seconds to obtain a molten material .

[0044] Step 2. Use the first-stage pre-plasticizing screw of the screw pre-plasticizer to inject the molten material into the second-stage injection rod, control the injection pressure of the first-stage pre-plasticization screw to 16MPa, and control the injection pressure of the second-stage injection rod to 12MPa; Then the molten material is injected into the mold cavity of the injection molding machine through the two-stage injection rod, and the injection time is 7 seconds.

[0045] Step ③. After keeping the pressure for 1.2 seconds, ...

Embodiment 2

[0048] First, choose recycled polyethylene, cast polypropylene film and masterbatches. Then, complete the steps as follows:

[0049] Step ①. Mix polyethylene, cast polypropylene film and color masterbatch according to the weight ratio of 0.8:0.6:0.012, mix and stir evenly, and add it to the hopper of the injection molding machine, heat to 190°C, and keep the heating time for 5 seconds to obtain a molten material .

[0050] Step 2. Use the first-stage pre-plasticizing screw of the screw pre-plasticizer to inject the molten material into the second-stage injection rod, control the injection pressure of the first-stage pre-plasticization screw to 14MPa, and control the injection pressure of the second-stage injection rod to 10MPa; Then the molten material is injected into the mold cavity of the injection molding machine through the second injection rod, and the injection time is 5 seconds.

[0051] Step ③. After holding the pressure for 1 second, pour water into the mold cavity...

Embodiment 3

[0054] First of all, directly purchase polyethylene, cast polypropylene film and color masterbatch from the market. Then, complete the steps as follows:

[0055] Step ①. Mix polyethylene, cast polypropylene film and color masterbatch according to the weight ratio of 1.3:1.4:0.018, mix and stir evenly, and add it to the hopper of the injection molding machine, heat to 200°C, and keep the heating time for 10 seconds to obtain a molten material .

[0056]Step 2. Use the first-stage pre-plasticizing screw of the screw pre-plasticizer to inject the molten material into the second-stage injection rod, control the injection pressure of the first-stage pre-plasticization screw to 20MPa, and control the injection pressure of the second-stage injection rod to 15MPa; Then the molten material is injected into the mold cavity of the injection molding machine through the second injection rod, and the injection time is 10 seconds.

[0057] Step ③. After maintaining the pressure for 1.8 sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com