Up-flow anaerobic ammonium oxidation granular sludge rectangular bed

An upflow anaerobic and granular sludge technology, applied in the direction of anaerobic digestion treatment, etc., can solve the problems of weak impact resistance, low mixing degree, easy to form dead ends, etc., to achieve enhanced impact resistance and good denitrification effect, the effect of uniform water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

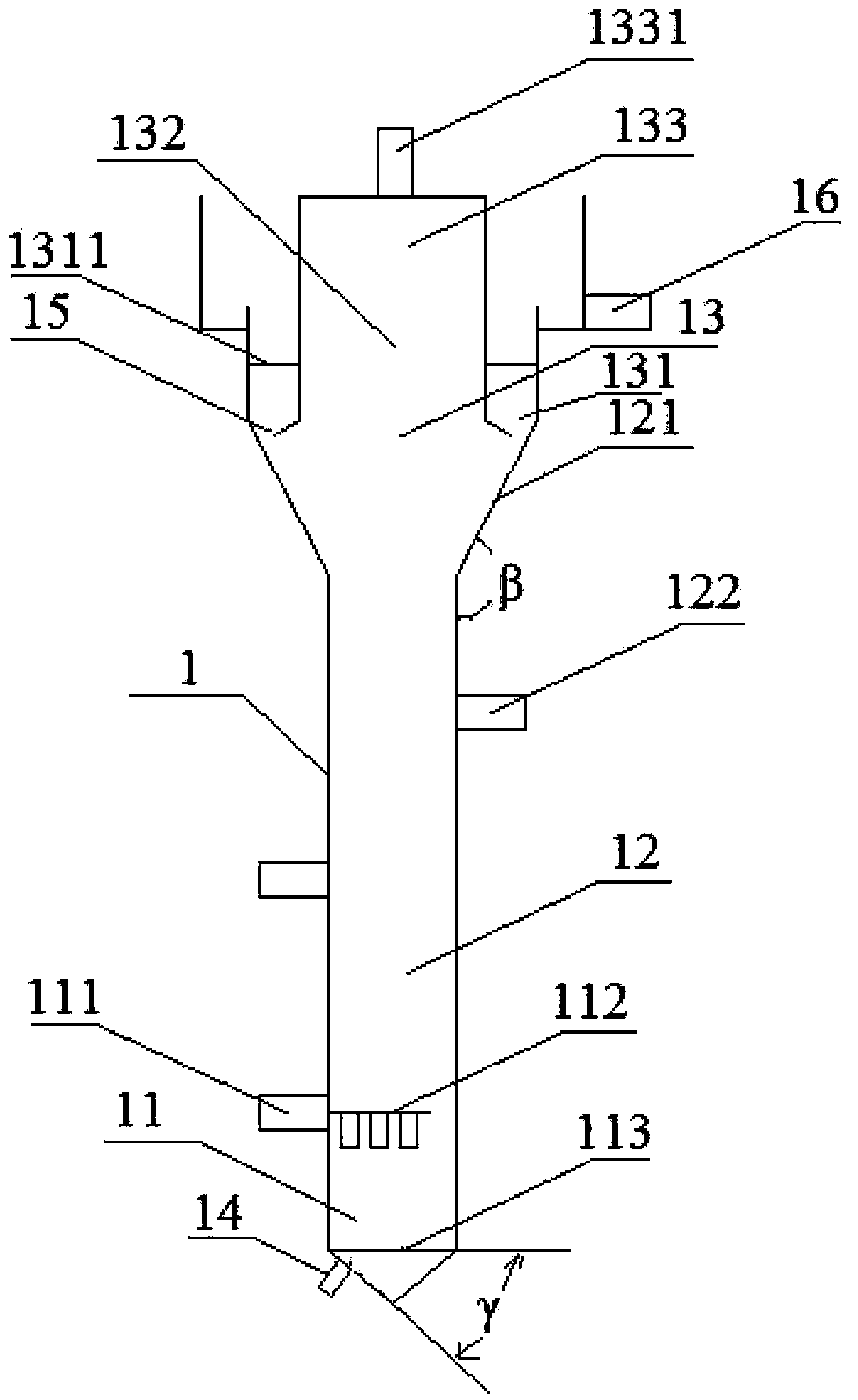

[0024] Example 1 An upflow anammox granular sludge rectangular bed according to the present invention includes a reactor body 1, and the reactor body 1 is divided into an inflow buffer zone 11, an upflow type The reaction chamber 12 and the three-phase separation zone 13, the water inlet buffer zone 11 is provided with a water inlet pipe 111 connected with the outside world, the water inlet pipe 111 is connected with an annular water distributor 112, and the lower end of the annular water distributor 112 is arranged A water outlet hole; the water inlet buffer zone 11 below the annular water distributor 112 is provided with a filter screen 113, and the reactor body 1 below the filter screen 113 is provided with a mud outlet 14; the upflow reaction The chamber 12 is connected with the settling chamber 131 of the three-phase separation zone 13 through the expanding pipe 121; the three-phase separation zone 13 is divided into a settling zone 131, a three-phase separation chamber 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com