Novel production technology of diosmin

A technology of diosmin and new technology, which is applied in the new technology field of diosin production, and can solve problems such as unstable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

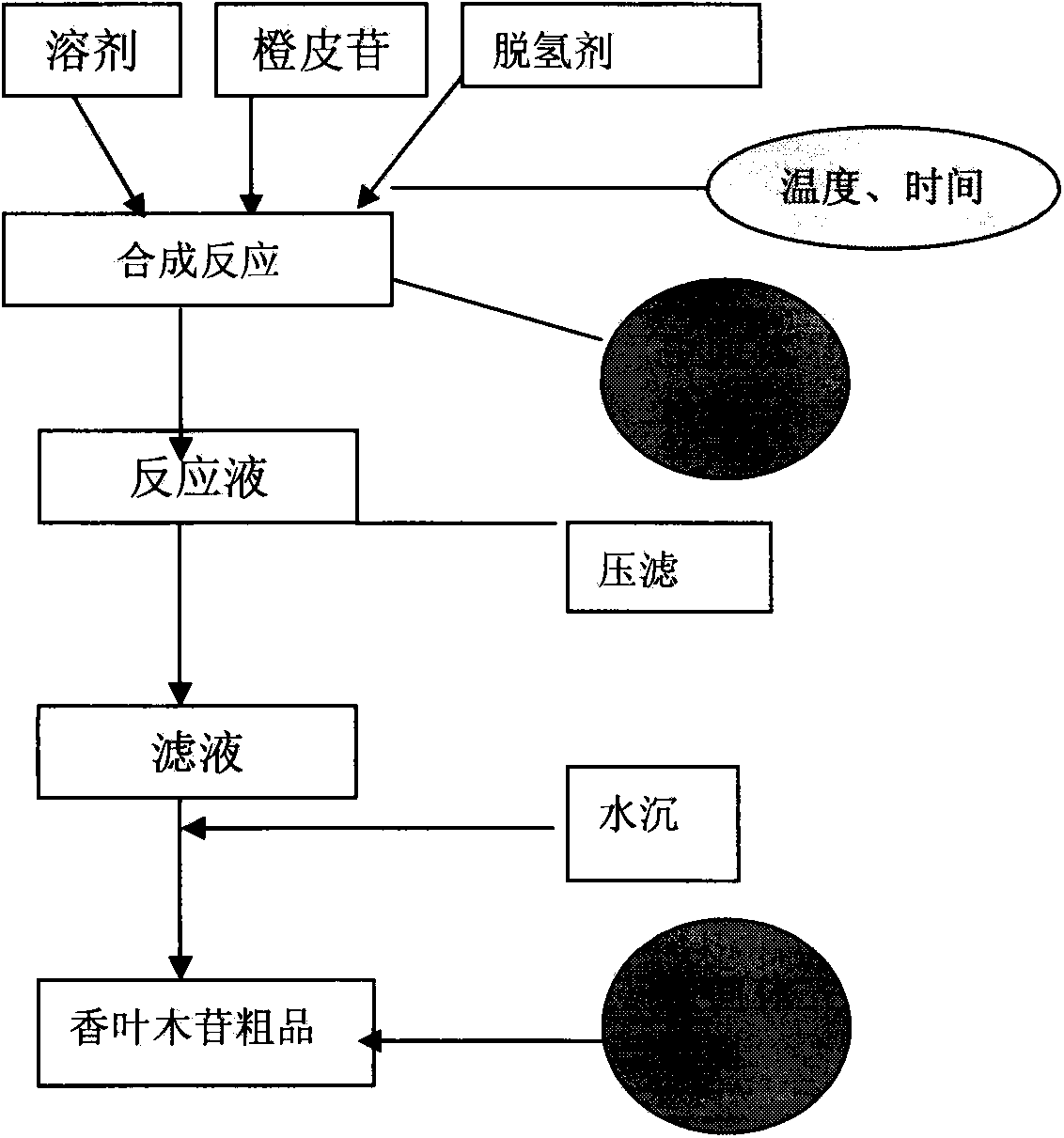

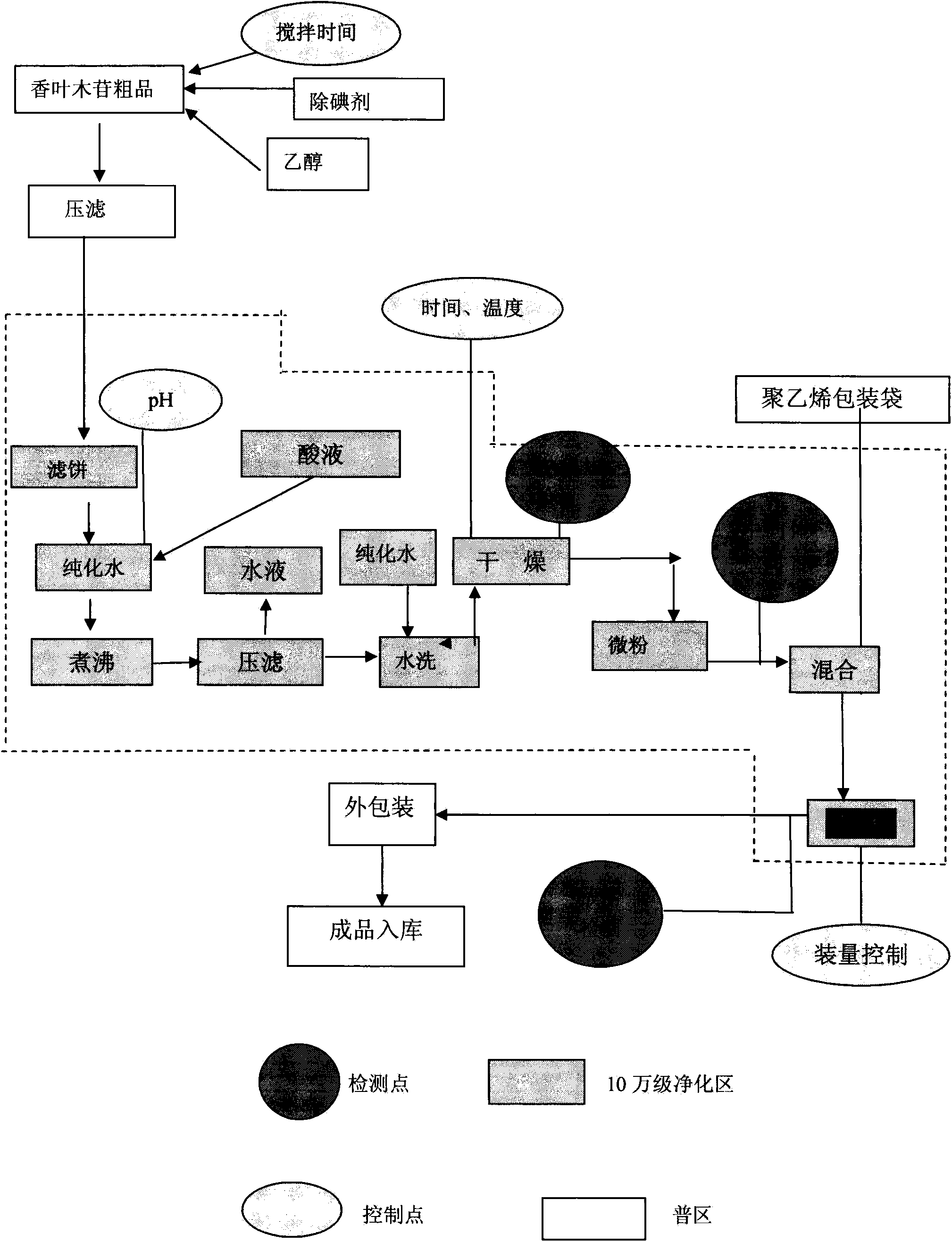

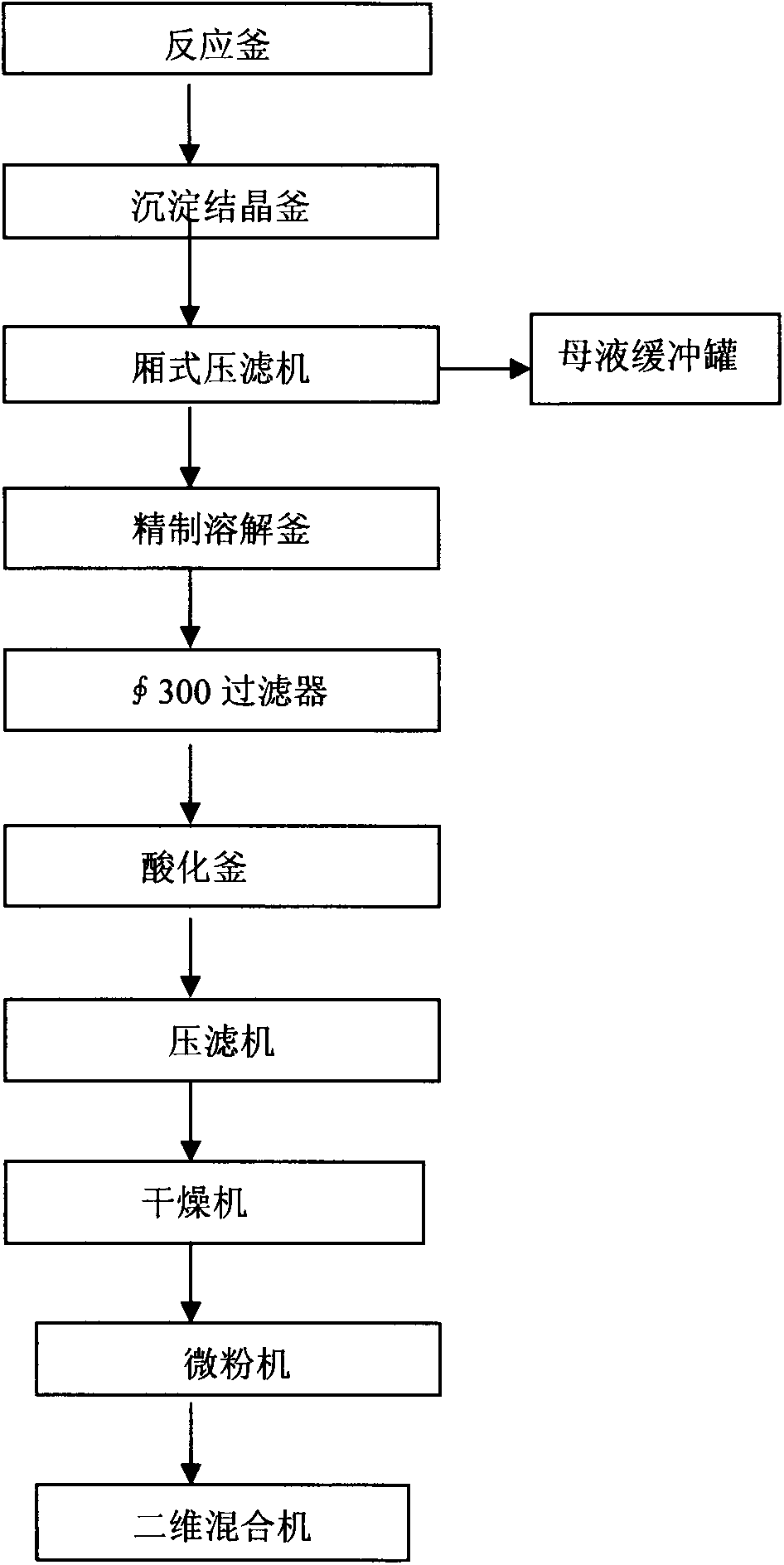

Method used

Image

Examples

Embodiment Construction

[0016] In a 500Kg reactor, add 300.0kg DMF, slowly add 100.0kg hesperidin, then add iodine 1.0~5.0kg and bromine water 1.0~3.0kg, slowly heat to 90~120℃ under stirring, and react at this temperature for 12~ 16h. Take a sample to detect the content of diosmin. When the content of hesperidin is lower than 1.0%, the reaction is finished, filtered, and the filtrate is recovered at 80-95° C. under a vacuum of - (0.05-0.07) Mpa to obtain a paste Dianoside. Add 1200kg of purified water to the paste-like diosmin, stir well, heat to 40-70°C, keep warm for 30-60min, press filter, wash with water until the outflowing water is clear. The filter cake was dried in an oven until the water content was 8-15%, and 108kg of the crude product was obtained. Put the crude product into the reaction kettle, add 864kg, 648kg, and 432kg of 85% ethanol respectively, and then add 400kg of iodine-removing agent, and stir and reflux for 60, 40, and 30 minutes respectively. Press filtration, wash the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com