Method for preparing diosmin by adopting continuous flow microreactor

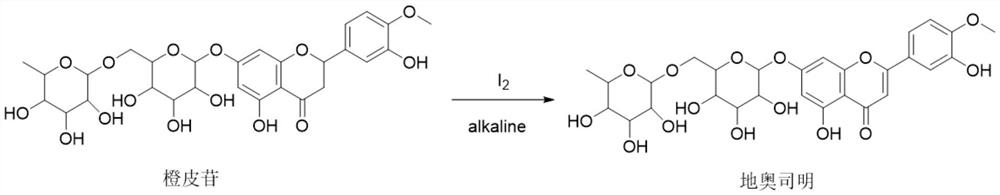

A technology of microreactor and diosmin, which is applied in the fields of chemical instruments and methods, chemical/physical/physicochemical reactors, preparation of sugar derivatives, etc., can solve the problem of greater harm to the environment and operators, long reaction time, Eliminate the strong irritating smell of pyridine and other problems, and achieve the effect of enhanced intrinsic safety and safe reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

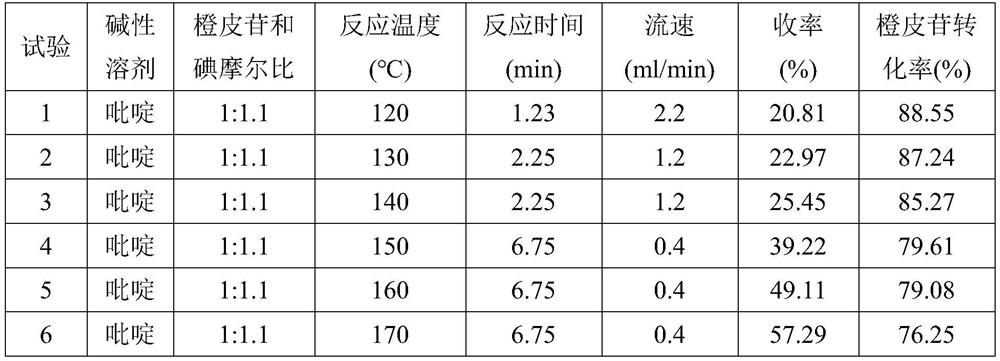

[0031] Example 1. Preparation of Diosmin by Continuous Flow Microreaction under Pressurization in the Present Invention

[0032] The specific method for preparing diosmin in a continuous flow microreactor under pressure is: adopt Corning microchannel continuous flow reactor (Corning lab-reactor, single module, liquid holding volume 2.7ml, two inlets and one outlet, heat exchange Oil pump rotation number 3500) as reaction equipment, and increase back pressure valve in reactor to increase system pressure, back pressure pressure is 10Bar. Hesperidin was formulated into a hesperidin solution with a concentration of 100mg / ml using an alkaline solvent, and iodine was formulated into an iodine solution with a concentration of 46mg / ml. The molar ratio and a certain flow rate are respectively injected into the reactor, and then the reaction is carried out to obtain a reaction liquid. The pH of the reaction solution was adjusted to neutral with 1 mol / L hydrochloric acid, and after bein...

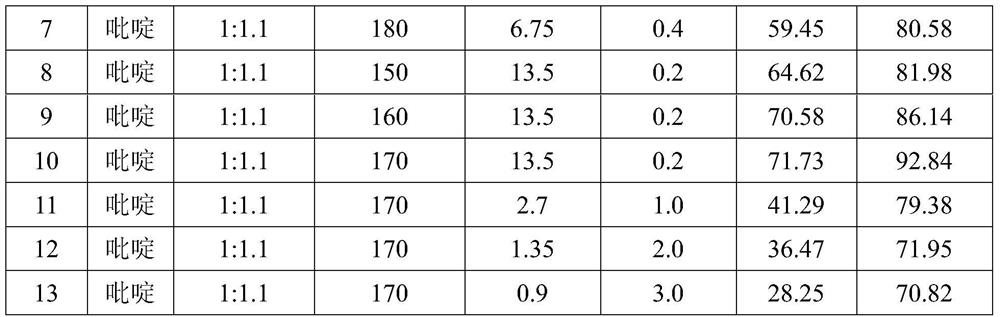

Embodiment 2

[0039] Example 2, Preparation of Diosmin by Continuous Flow Microreaction under Pressurization in the Present Invention

[0040] The specific method for preparing diosmin in a continuous flow microreactor under pressure is: adopt Corning microchannel continuous flow reactor (Corning lab-reactor, single module, liquid holding volume 2.7ml, two inlets and one outlet, heat exchange Oil pump rotation number 3500) as reaction equipment, and increase back pressure valve in reactor to increase system pressure, back pressure pressure is 10Bar. Hesperidin was formulated into a hesperidin solution with a concentration of 100 mg / ml using an alkaline solvent, and iodine was formulated into an iodine solution with a concentration of 46 mg / ml. The molar ratio was stirred and mixed under normal pressure at 10° C. for 30 minutes, and then injected into the reactor at a certain flow rate for reaction to obtain a reaction liquid. The pH of the reaction solution was adjusted to neutral with 1 m...

Embodiment 3

[0046] Example 3, Preparation of Diosmin by Continuous Flow Microreaction under Normal Pressure of the present invention

[0047] The specific method for preparing diosmin in a continuous flow microreactor under normal pressure is: adopt Corning microchannel continuous flow reactor (Corning lab-reactor, single module, liquid holding volume 2.7ml, two inlets and one outlet, heat exchange Oil pump revolutions 3500) as reaction equipment. Hesperidin is formulated into a hesperidin solution with a concentration of 100mg / ml using an alkaline solvent, and iodine is formulated into an iodine solution with a concentration of 46mg / ml; The molar ratio and a certain flow rate are respectively injected into the reactor, and then the reaction is carried out to obtain a reaction liquid. The pH of the reaction solution was adjusted to neutral with 1 mol / L hydrochloric acid, and after being diluted with DMSO to constant volume, it was analyzed by HPLC to determine the yield of the product di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com