Highland barley za wine and preparation method thereof

A production method and highland barley technology, which are applied in the preparation of alcoholic beverages, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems that do not involve the production method of highland barley wine, do not involve the production method of highland barley wine, etc. The effect of high appearance quality, golden color and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

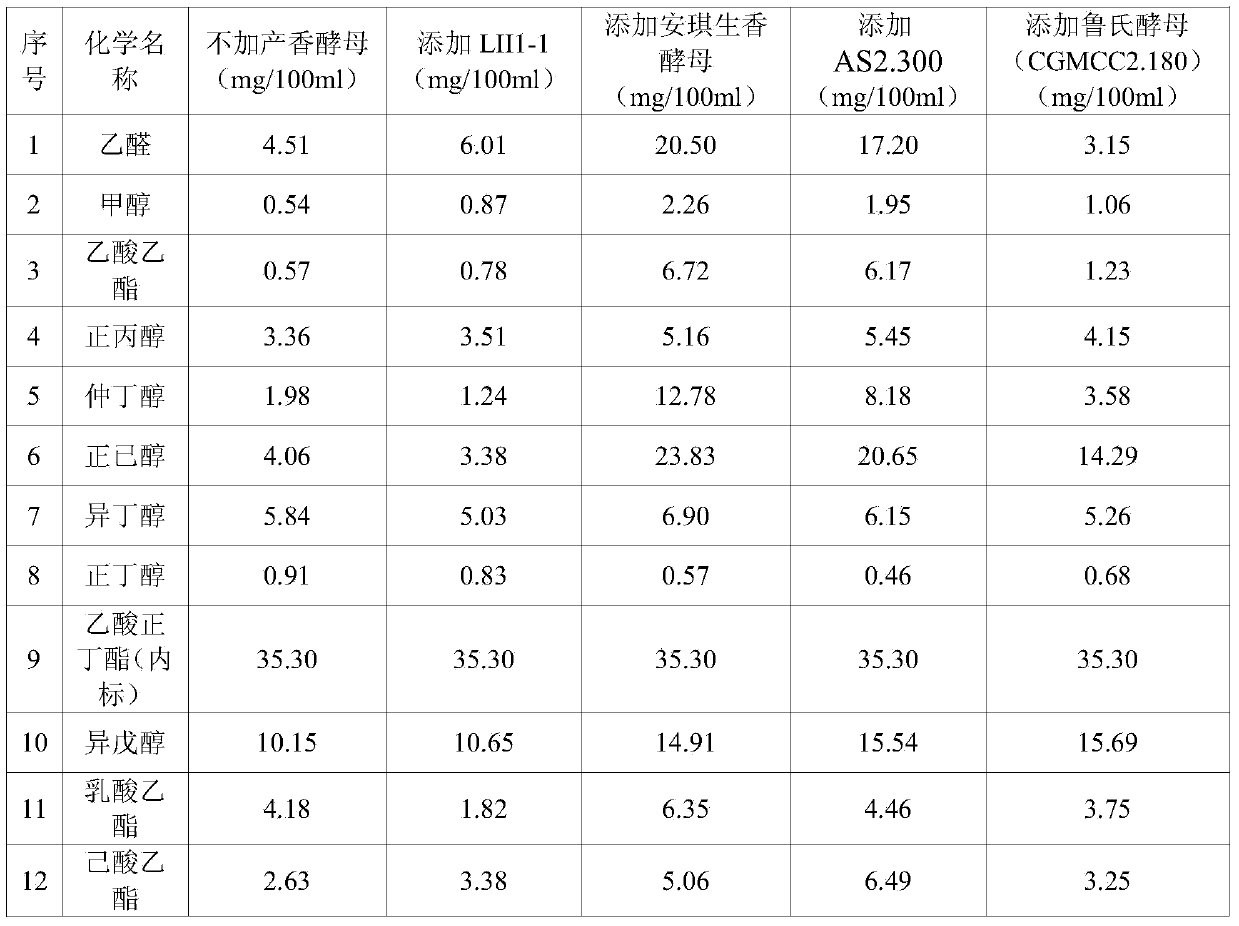

Embodiment 1

[0074] After washing 2000kg of highland barley, soak it in water at 20°C for 24 hours in a rice soaking tank, and the liquid level is 10cm higher. After the highland barley is soaked and drained, crush the highland barley to 5 mesh with a crusher, then add 2kg of crushed black malt, mix well and cook in a rice steamer, and cook for 25 minutes from the time of SAIC. Air-cool the boiled raw materials to 28°C, add 20kg of Q303 rhizopus barley koji and 1kg of Angelica ester-producing active dry yeast, mix them with a rotary mixer, put them into the tank and start saccharification. The total time of saccharification is 5 days, of which the 3rd Take out the 20% saccharification solution in the tank, sterilize it at 137°C for 5s, and store it in a dry and cool place for the final blending of Zajiu. After saccharification, add water equal to the weight of the raw materials into the fermenter, mix evenly with a stirring paddle, let it stand for 12 hours, and stir for 2 minutes every 1 ...

Embodiment 2

[0077] After washing 2000kg of highland barley, soak it in water at 25°C for 24 hours in a rice soaking tank, and the liquid level is 5cm higher. After the highland barley is soaked and drained, crush the highland barley to 5 mesh with a crusher, then add 10kg of crushed black malt, mix well and cook in a rice steamer, and cook for 25 minutes from the time of SAIC. Air-cool the boiled raw materials to 28°C, add 10kg of raw material weight C-24 rhizopus barley koji and 1kg of Angelica ester-producing active dry yeast, mix them with a rotary mixer, put them into the tank and start saccharification, the total time of saccharification is 5d , where 20% of the saccharification solution in the tank was taken out on the 3rd day, sterilized at 137°C for 5s and stored in a dry and cool place for the final blending of the wine. After saccharification, add water equal to the weight of the raw materials into the fermenter, mix evenly with a stirring paddle, let it stand for 12 hours, and ...

Embodiment 3

[0080] After washing 2000kg of highland barley, soak it in 35°C water for 24 hours in a rice soaking tank, and the liquid level is 5cm higher. After soaking and draining the highland barley, crush the highland barley to 10 meshes with a crusher, then add 16kg of crushed black malt, mix well and cook in a rice steamer, and cook for 25 minutes from the time of SAIC. Air-cool the boiled raw materials to 25°C, add 40kg of AS3.866 Rhizopus barley koji and 2kg of Angie ester-producing active dry yeast, mix them with a rotary mixer and put them into the tank to start saccharification. The total time of saccharification is 5 days , where 20% of the saccharification solution in the tank was taken out on the 3rd day, sterilized at 137°C for 5s and stored in a dry and cool place for the final blending of the wine. After saccharification, add water equal to the weight of the raw materials into the fermenter, mix evenly with a stirring paddle, let it stand for 12 hours, and stir for 2 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com