MOCVD reactor and support shaft for MOCVD reactor

A technology for supporting shafts and reactors, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problems of prolonging normal working hours, large thermal conductivity, large heat transfer, etc., and achieve easy and uniform thermal field , Calorie reduction, easy to form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

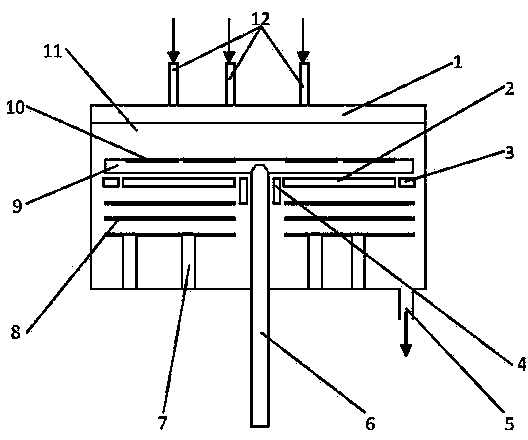

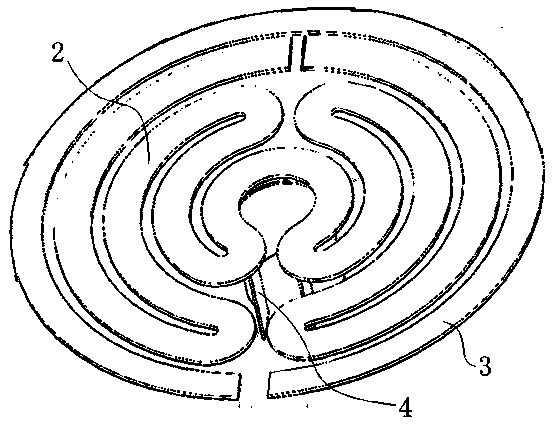

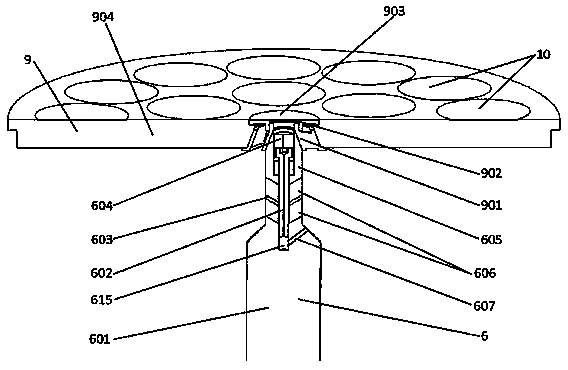

[0065] image 3 Shown is a schematic diagram of an implementation example of the present invention, Figure 4 for image 3 A partial enlargement of the . combine image 3 and Figure 4 It can be seen that the rotating support shaft 6 of the wafer carrier mainly includes a bottom portion 601 of the rotating supporting shaft, a top portion 605 of the rotating supporting shaft, a heat insulating sleeve 606 , and a reinforcing sleeve 603 . The components of the above-mentioned rotating support shaft are fastened together by screws 602 to form a whole. In order to enhance the heat insulation effect, a heat insulation pad 610 and a gasket 609 for protecting the heat insulation pad are distributed under the screw head or the bolt head 604, and a heat insulation cover 604 is distributed above the screw head or the bolt head. The wafer carrier 9 is coupled to the top 605 of the rotating support shaft 6 , and the wafer carrier 9 mainly includes a connecting ring 901 , a fixed cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com