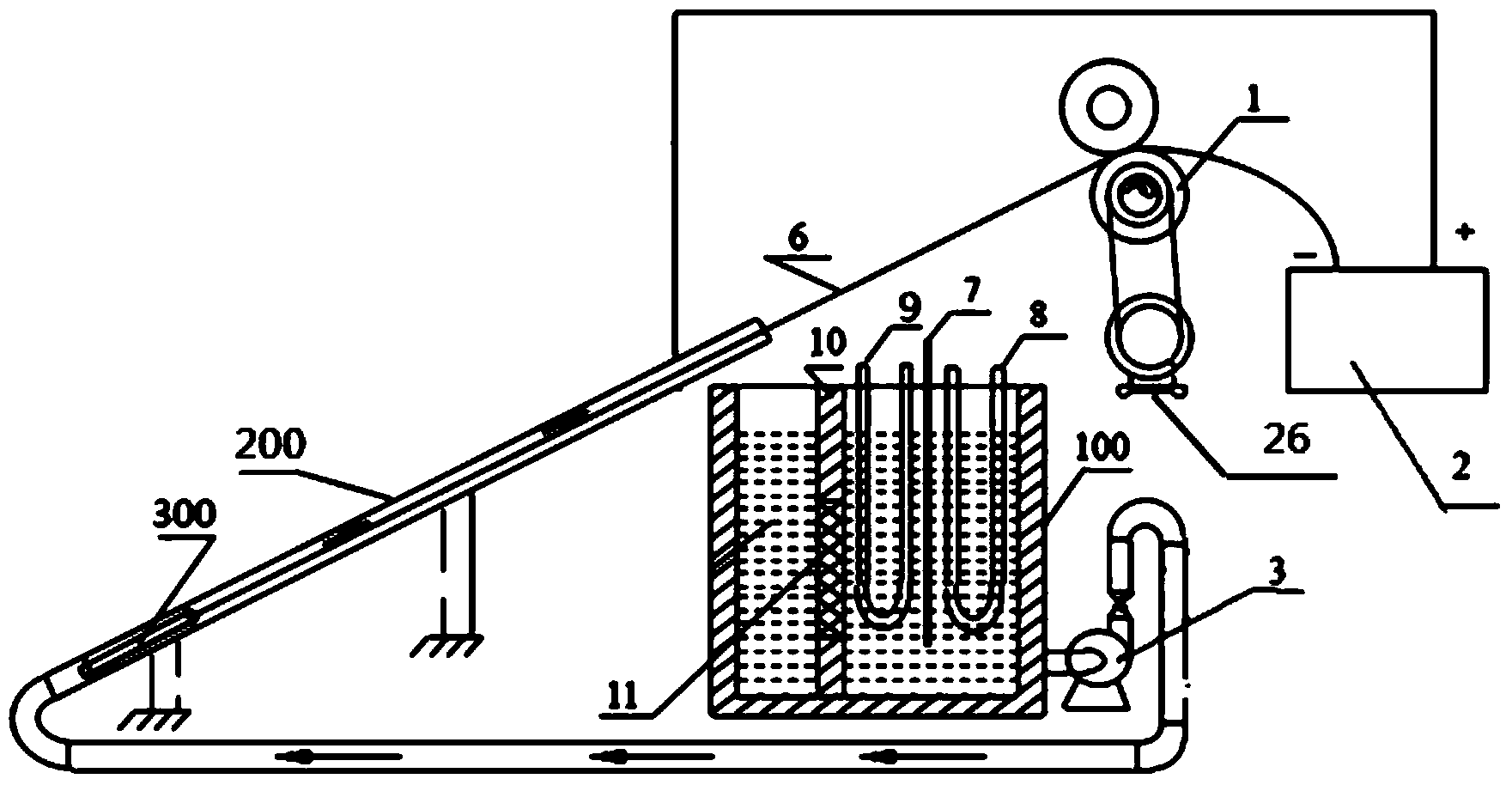

Electrochemical polishing liquid for inner wall of stainless steel pipe as well as polishing method and device of electrochemical polishing liquid

A stainless steel tube and polishing liquid technology, applied in the field of stainless steel surface treatment, can solve problems such as affecting polishing quality, affecting polishing effect, and being difficult to dissipate, and achieving the effect of ensuring polishing quality and excellent electrochemical polishing surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

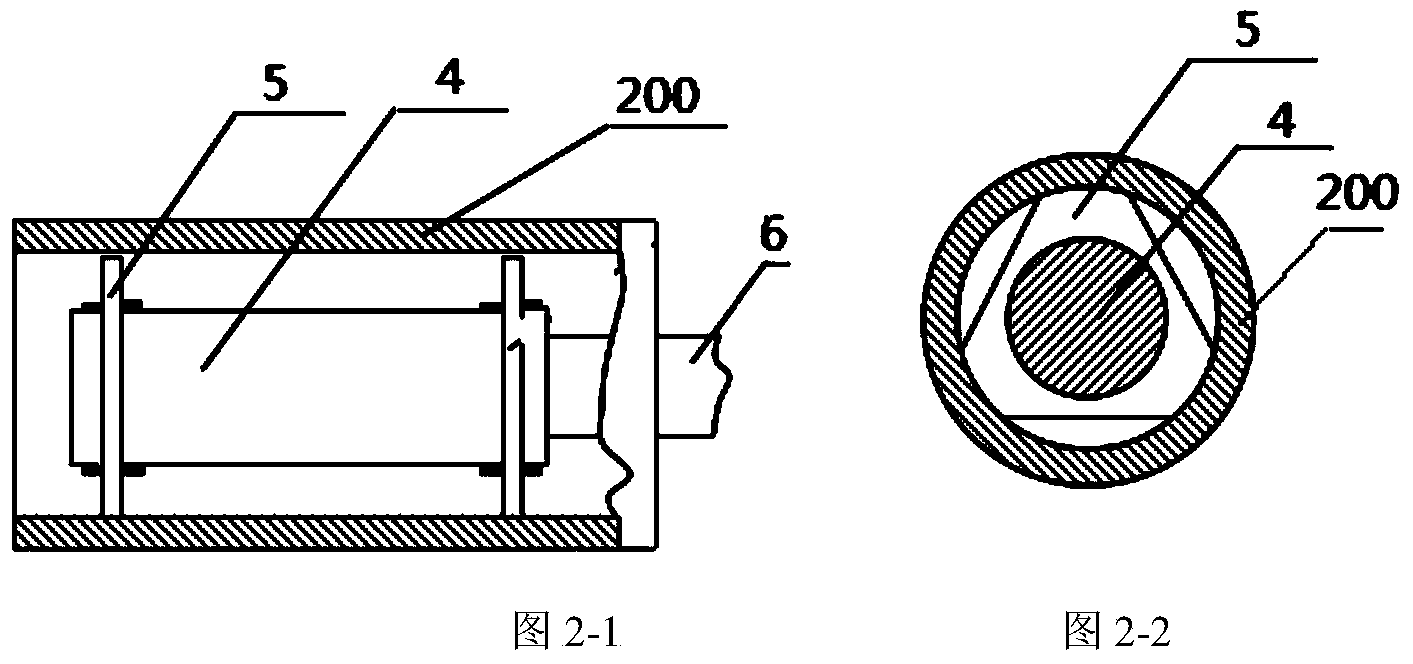

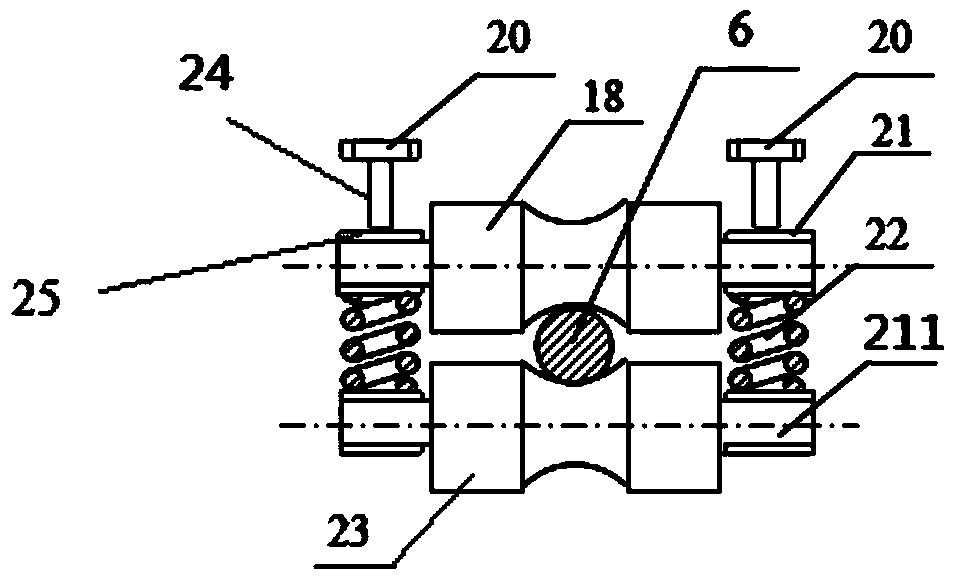

Method used

Image

Examples

Embodiment 1

[0041] The inner wall of a 304 stainless steel pipe with a length of Ф20 and a length of 12 meters is electrochemically polished. The composition and weight of the polishing solution and the operating parameters are as follows.

[0042] Phosphoric acid 79.5 parts, sulfuric acid 45.1 parts, ethylene glycol 1.7 parts, citric acid 1.7 parts, polyvinylpyrrolidone 0.1 parts, ethylenediaminetetraacetic acid 0.8 parts, saccharin 0.3 parts, water 100 parts. Temperature 40℃, current density 10A / dm 2 , Cathode moving speed 50mm / min.

[0043] The density of phosphoric acid is 1.7, the density of sulfuric acid is 1.84; the viscosity average molecular weight of polyvinylpyrrolidone is 35000;

[0044] The surface roughness of the inner wall of the stainless steel tube treated by the process in this example can reach 0.01 μm, and the inner surface of the austenitic stainless steel tube achieves a mirror effect, and the reflectivity is greater than 98%.

Embodiment 2

[0046] The inner wall of Ф20 304 stainless steel pipe with a length of 12 meters is electrochemically polished. The composition and weight of the polishing solution and the operating parameters are as follows:

[0047] 105 parts of phosphoric acid, 60 parts of sulfuric acid, 3 parts of ethylene glycol, 3 parts of citric acid, 0.2 parts of polyvinylpyrrolidone, 2 parts of ethylenediaminetetraacetic acid, 0.8 parts of saccharin, and 100 parts of water. Temperature 60℃, current density 30A / dm 2, Cathode moving speed 50mm / min.

[0048] The density of phosphoric acid is 1.7, the density of sulfuric acid is 1.84; the viscosity average molecular weight of polyvinylpyrrolidone is 30000;

[0049] Cathode moving speed 30mm / min.

[0050] The surface roughness of the inner wall of the stainless steel tube treated by the process in this example can reach 0.01 μm, and the inner surface of the austenitic stainless steel tube achieves a mirror effect, and the reflectivity is greater than 98...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com